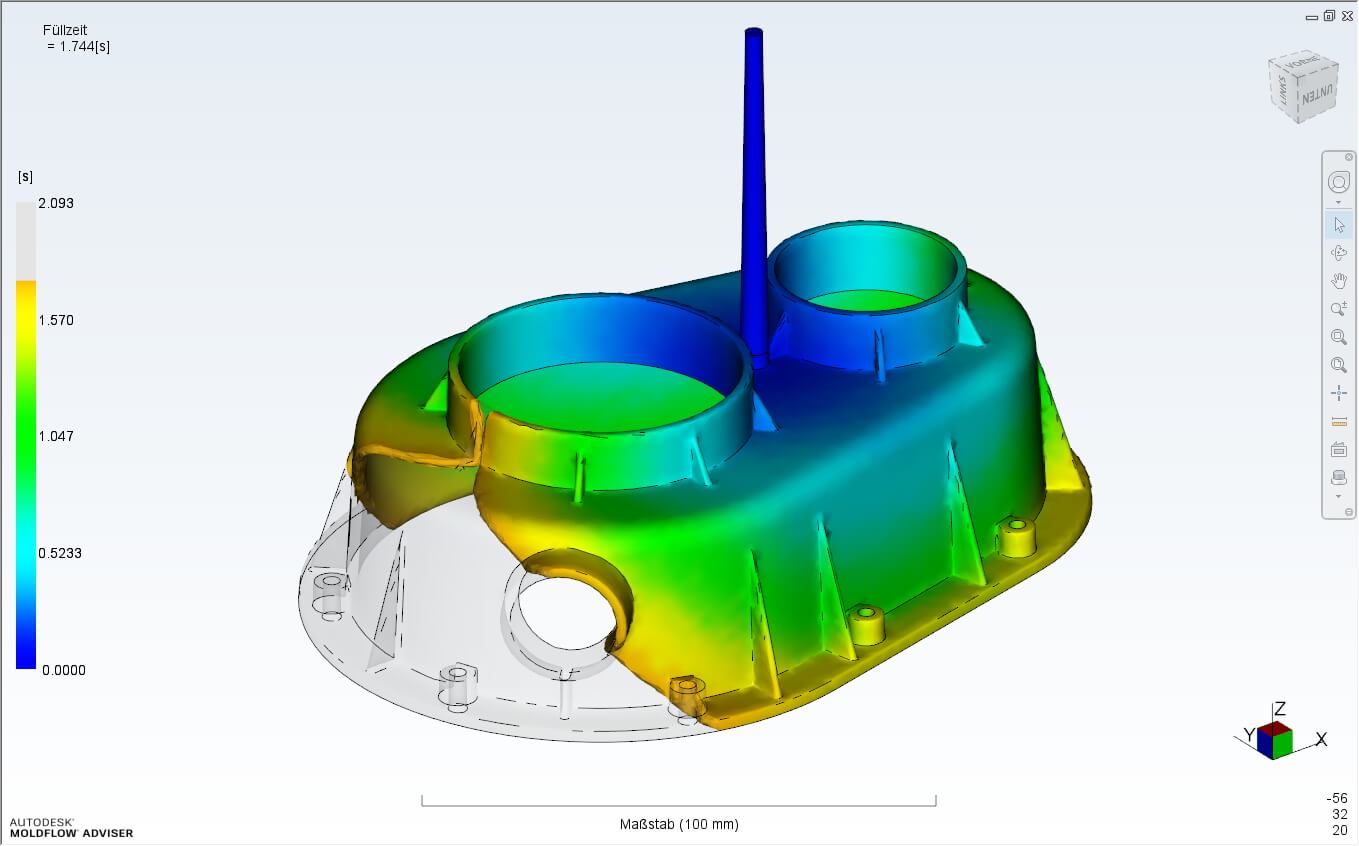

Moldflow Adviser

To improve the quality of your manufactured parts and produce them even more cost-efficiently.

Autodesk Moldflow Adviser is the ideal tool for validating and optimizing your plastic or injection-moulded parts, even during the development phase.

Autodesk Moldflow Adviser gives you the opportunity to reduce the number of physical prototypes and replace them with digital prototypes, thereby dramatically reducing development costs. In addition, you accelerate product development and thus shorten the time required to bring your product to market.

- Optimize workpieces and shapes

- Improve solver capacity with flexible calculations

- Connecting workflows

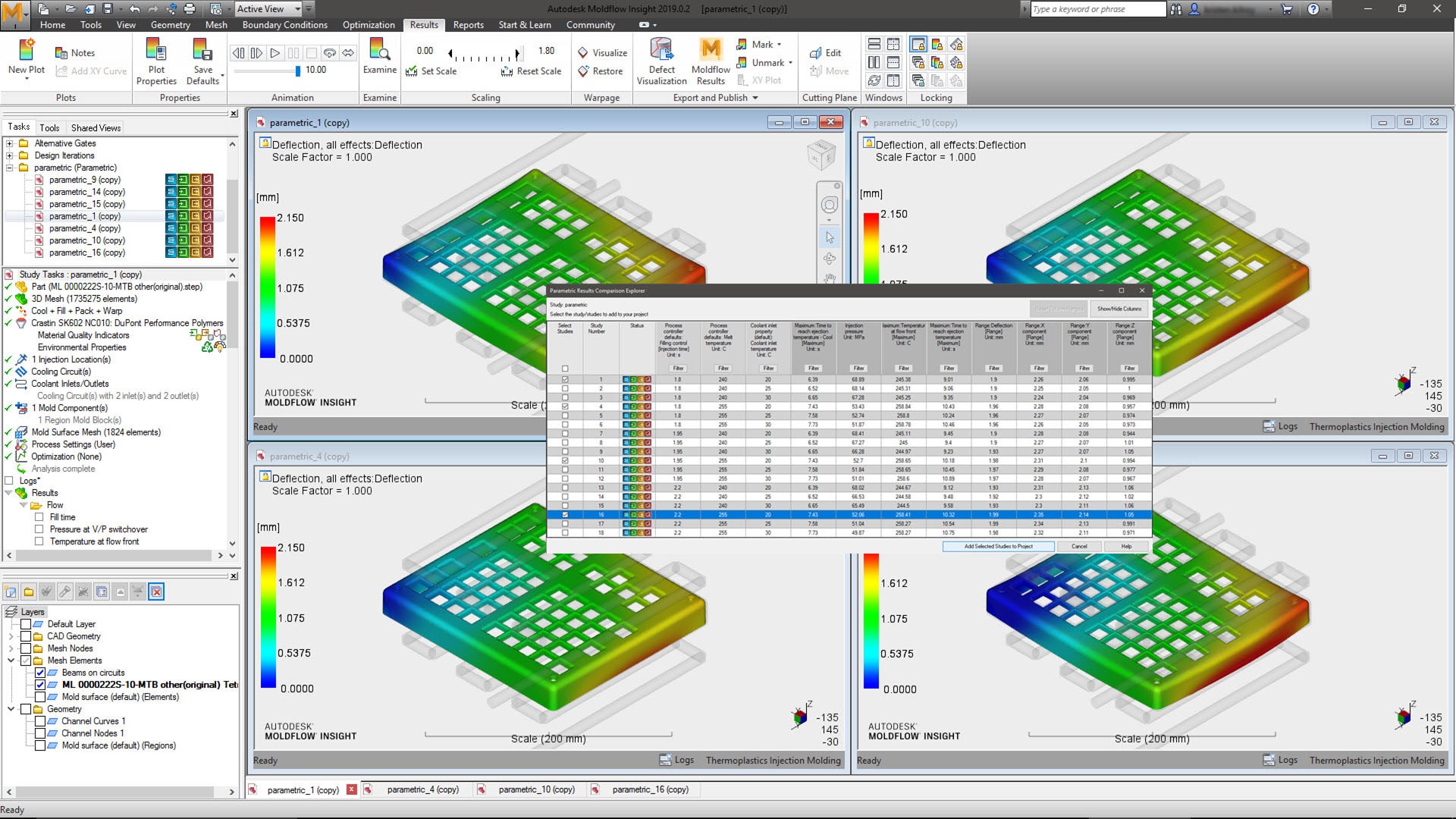

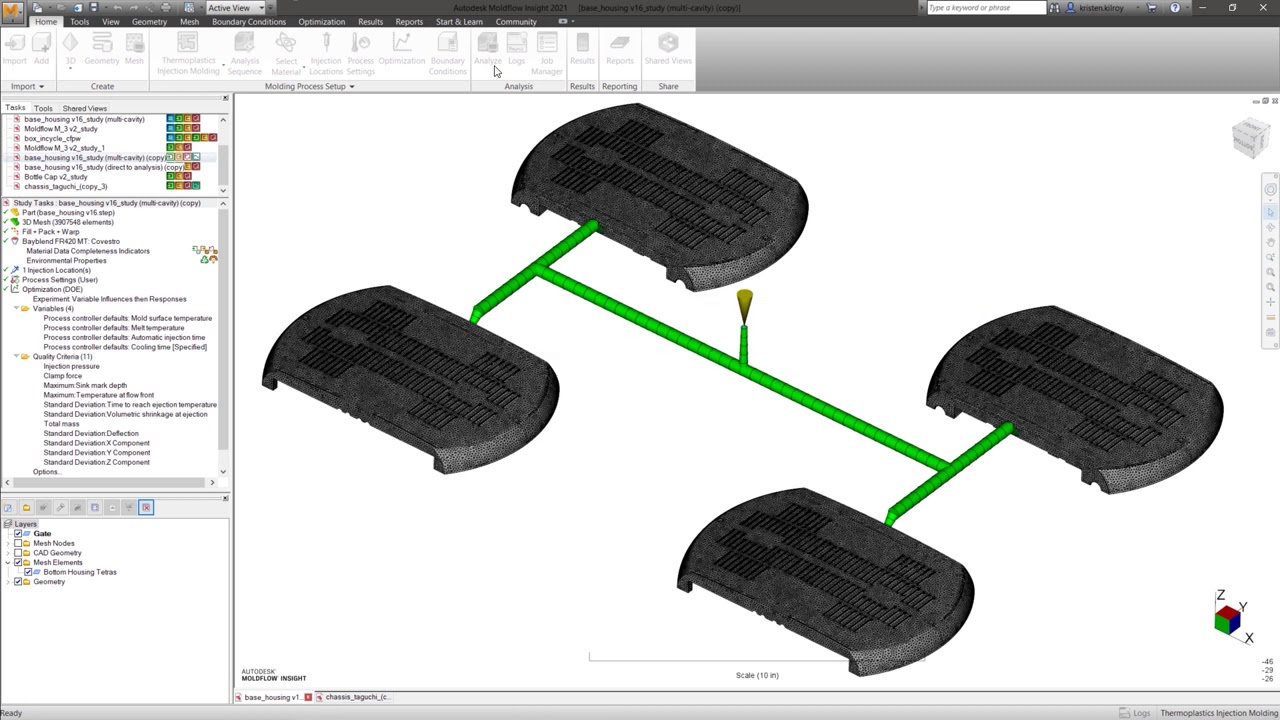

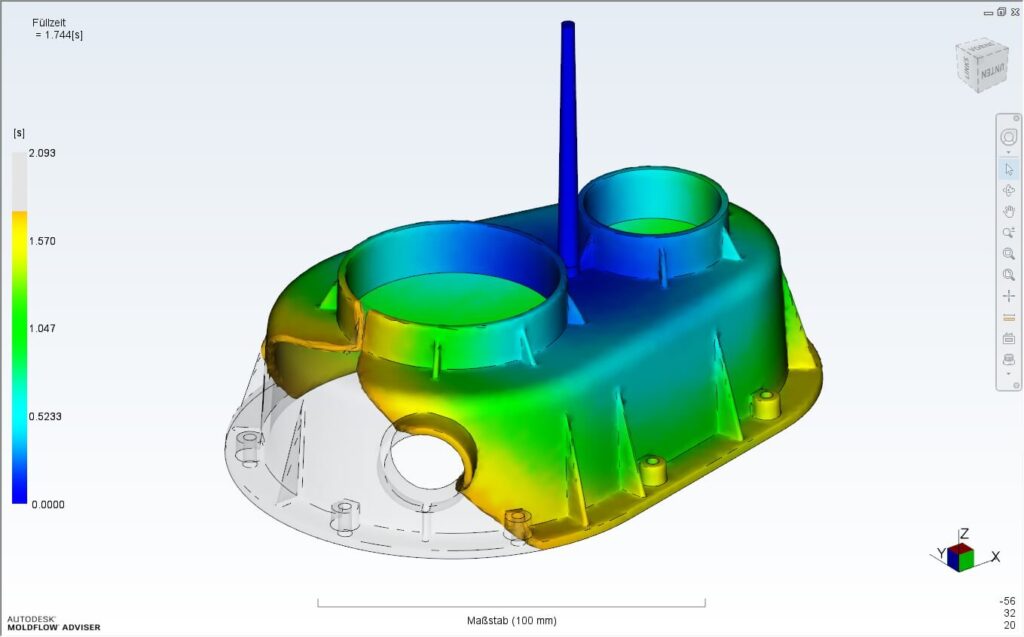

Optimize workpieces and processes

Analyze single or multiple tools to determine part manufacturability, tool design, material selection and process optimization. Model or import cooling systems and sprue systems.

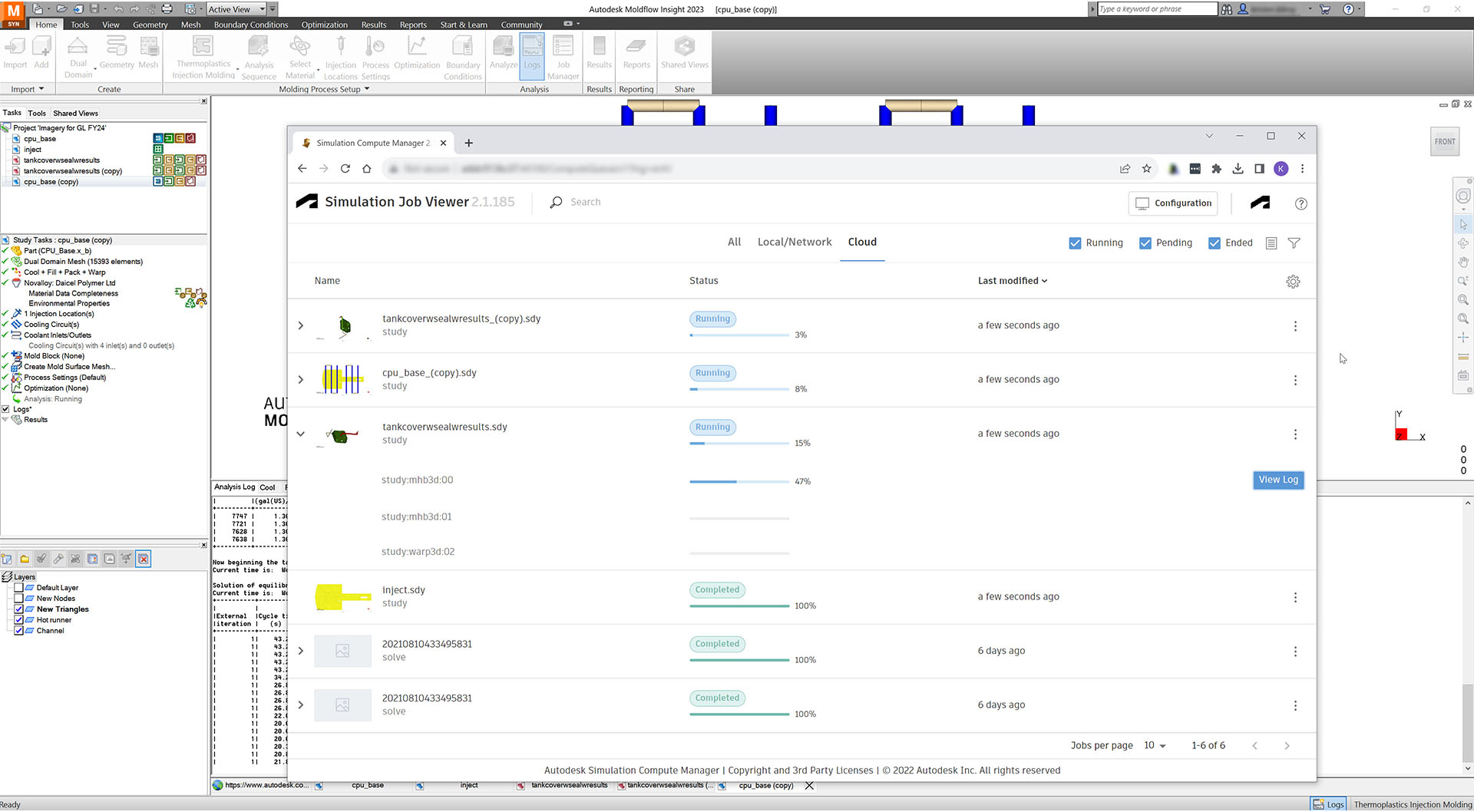

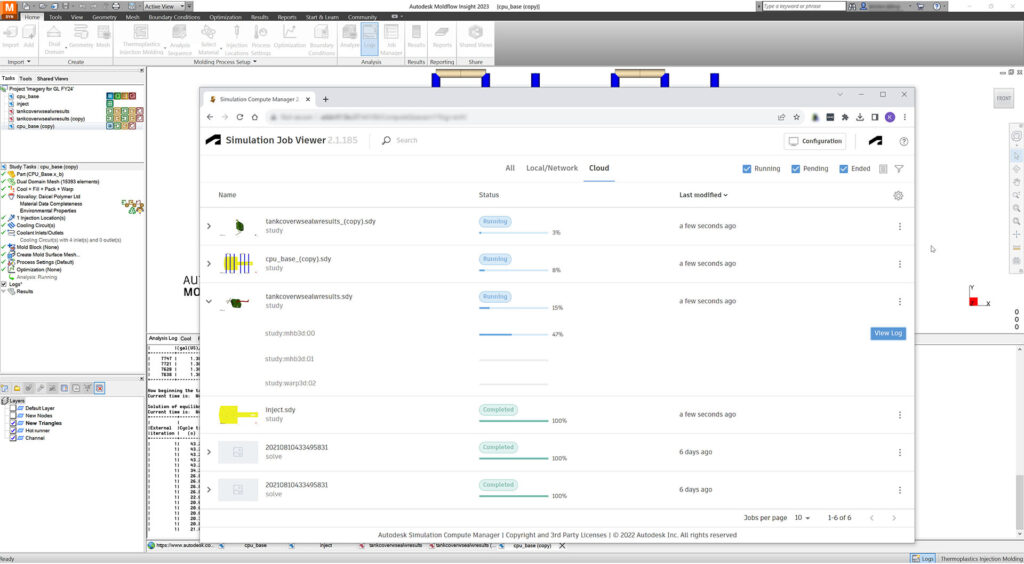

Improve solver capacity with flexible calculations

Run multiple simulations simultaneously to quickly discover optimal designs.

Network and calculate Moldflow Insight simulation jobs via local, remote and secure cloud servers. Run multiple simulations simultaneously.

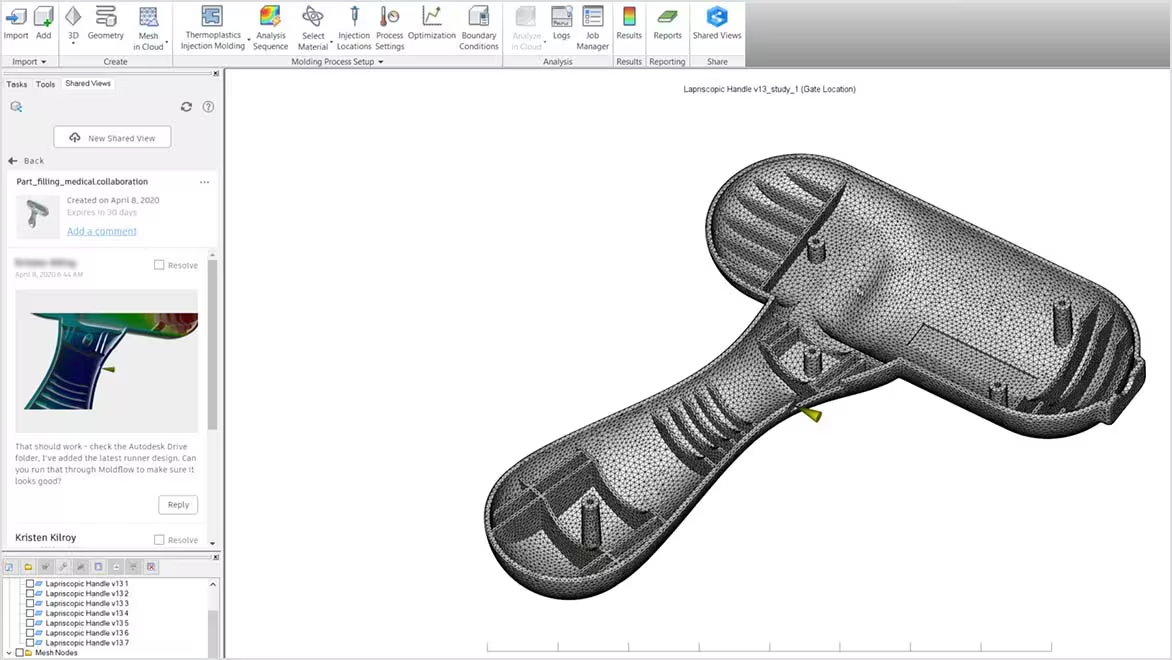

Connecting workflows

Connect product development teams with Autodesk Drive and shared views to minimize delays and costly rework.

With the in-product push function to Fusion 360, you can make geometry changes more quickly. Export CAD and results for post-processing.

Functions

Predict the quality of molded parts and correct errors earlier.

Optimize mould designs, including the arrangement of cavities, feed and cooling.

Use process optimization to find the ideal processing window.

Receiving fast, uncomplicated support from a competent partner like WESTCAM is extremely valuable.

Frequently asked questions (FAQs)

What is Autodesk Moldflow?

Autodesk Moldflow is used to simulate injection molding and injection compression molding processes for plastics.

Engineers, analysts and mold makers can use it to optimize material selection, process settings, cooling efficiency and gating system designs to minimize the risk of poor part quality.

Autodesk Moldflow simulations provide analysts with insights that help predict and potentially avoid defects in molded parts such as sink marks, weld lines and warpage. They can also investigate options for reducing cycle time.

Can I perform calculations in the cloud with Moldflow Insight?

Moldflow Insight has an option for calculation in the cloud with Autodesk tokens. The cost of the cloud calculation varies depending on the simulation study type. This calculation in the cloud is provided in addition to the local and remote server calculation options from Moldflow Insight.

What is different about Moldflow Adviser and Moldflow Insight?

In contrast to Autodesk Moldflow Insight, the Adviser is designed for simulation during the design process. The use of Autodesk Moldflow Adviser is particularly simple and intuitive and supports the designer with essential information on filling, shrinkage, warpage, etc. and thus allows the designer to assess the design in the very early product development phase and design accordingly.