ScanBox for eMotors

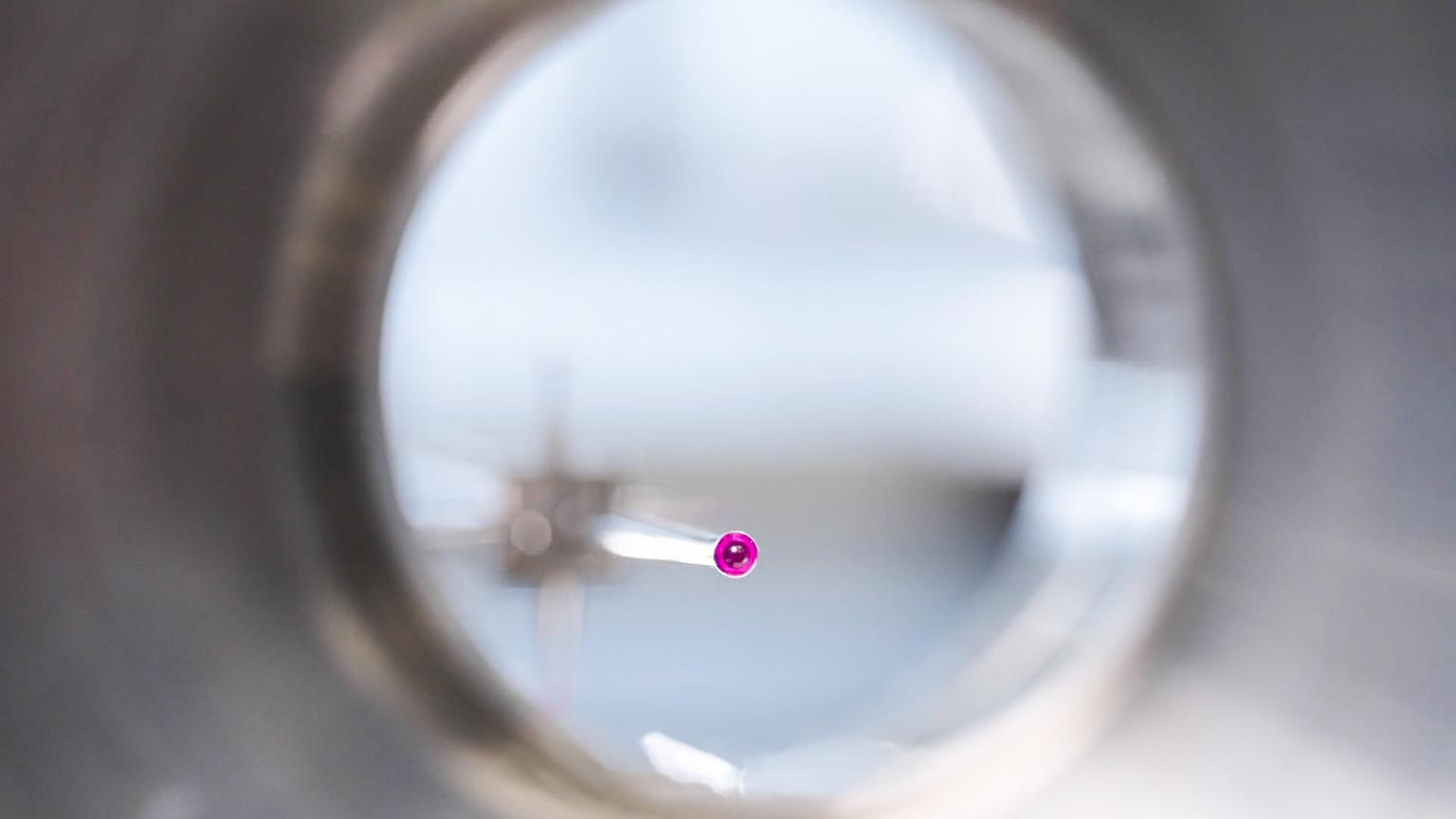

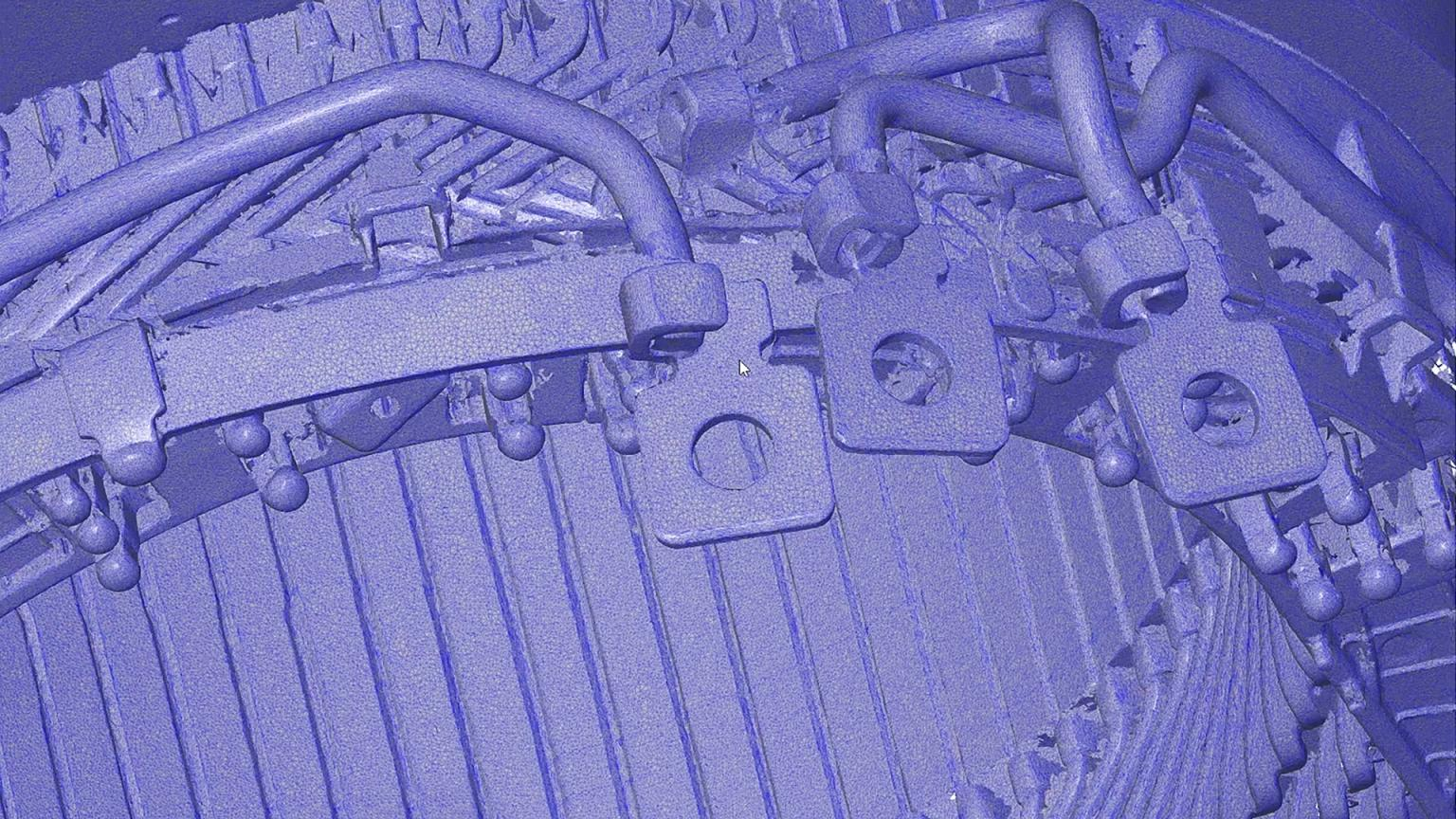

Precise inspection and digitization of hairpins & stators.

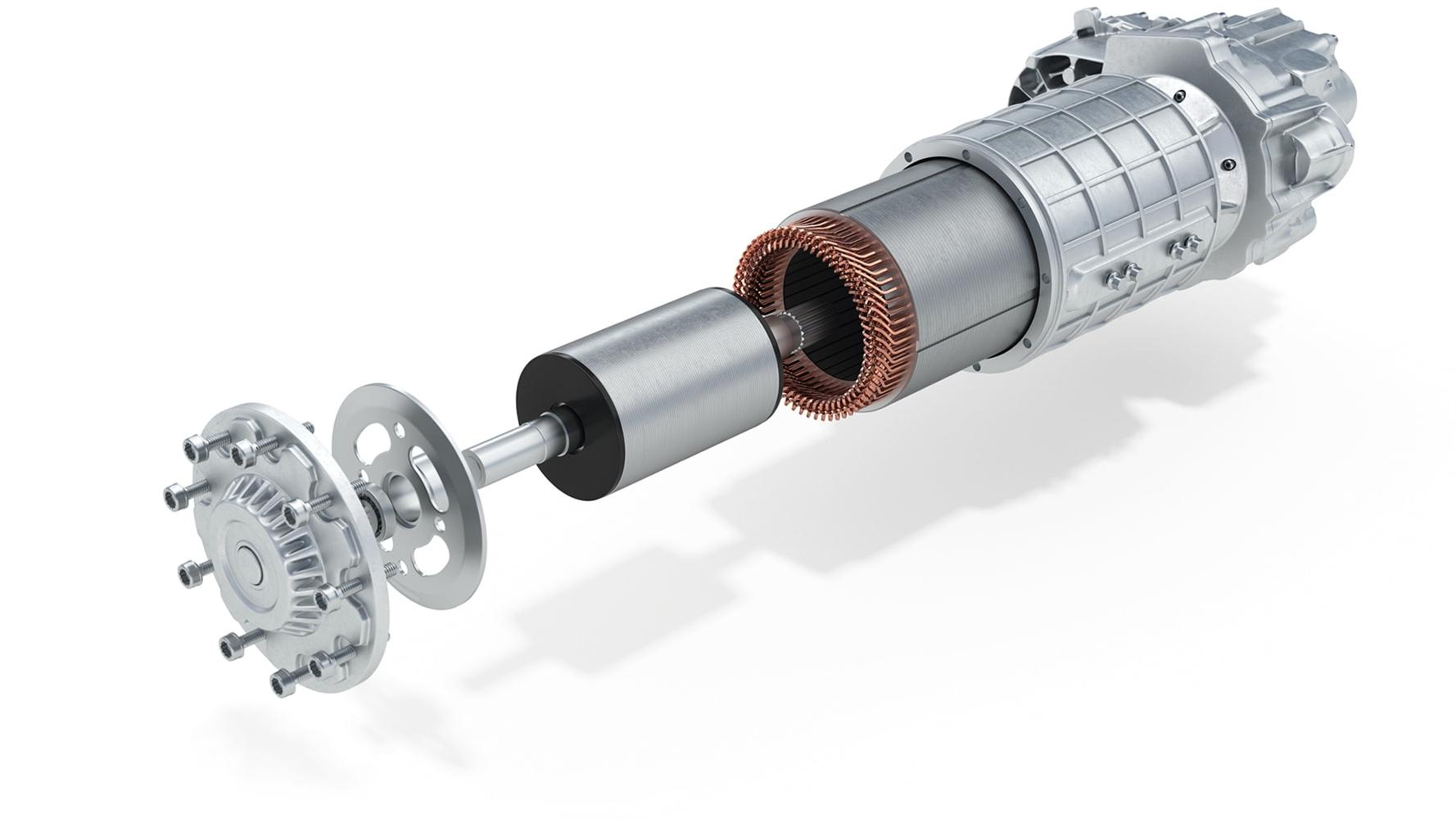

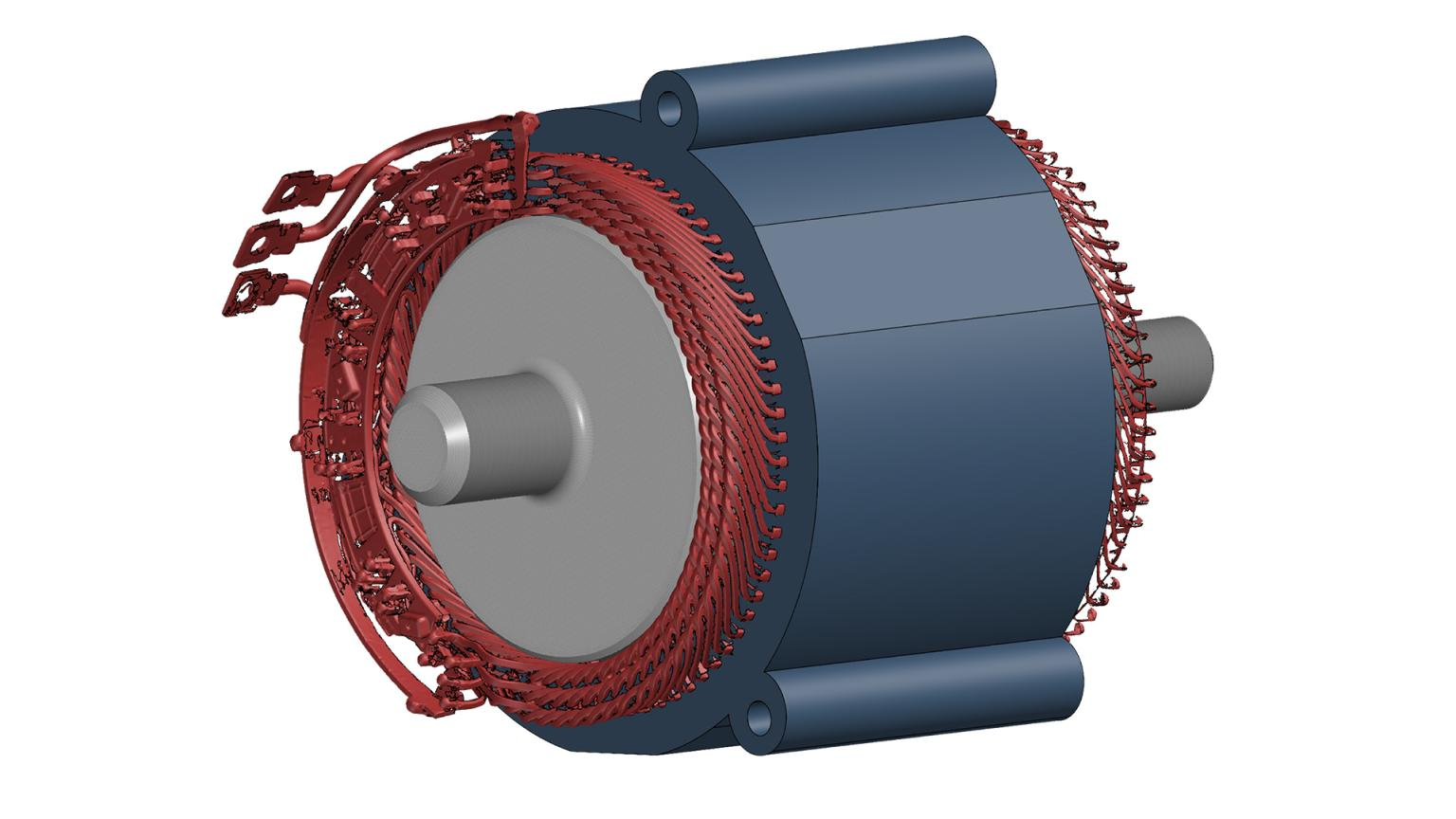

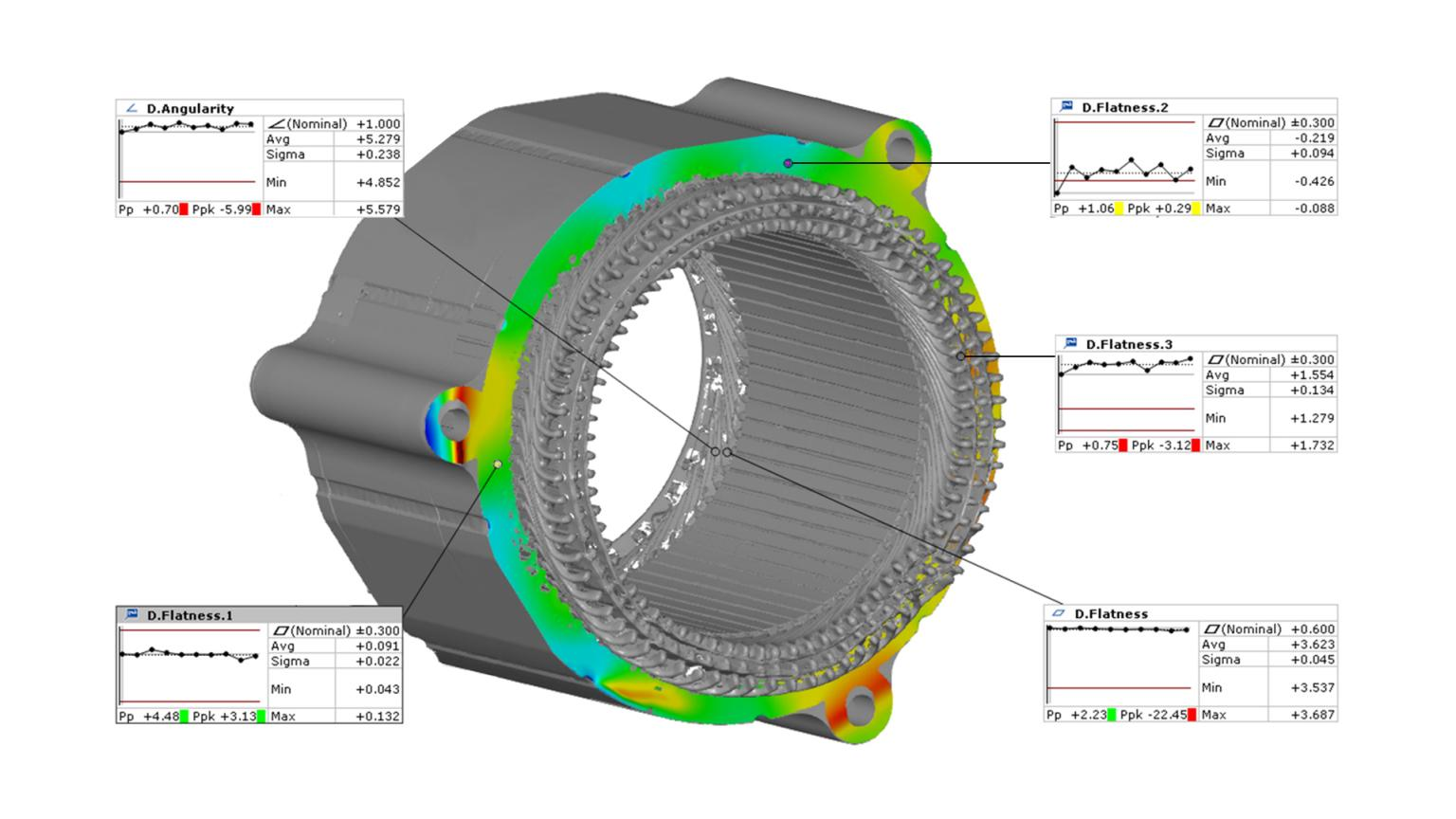

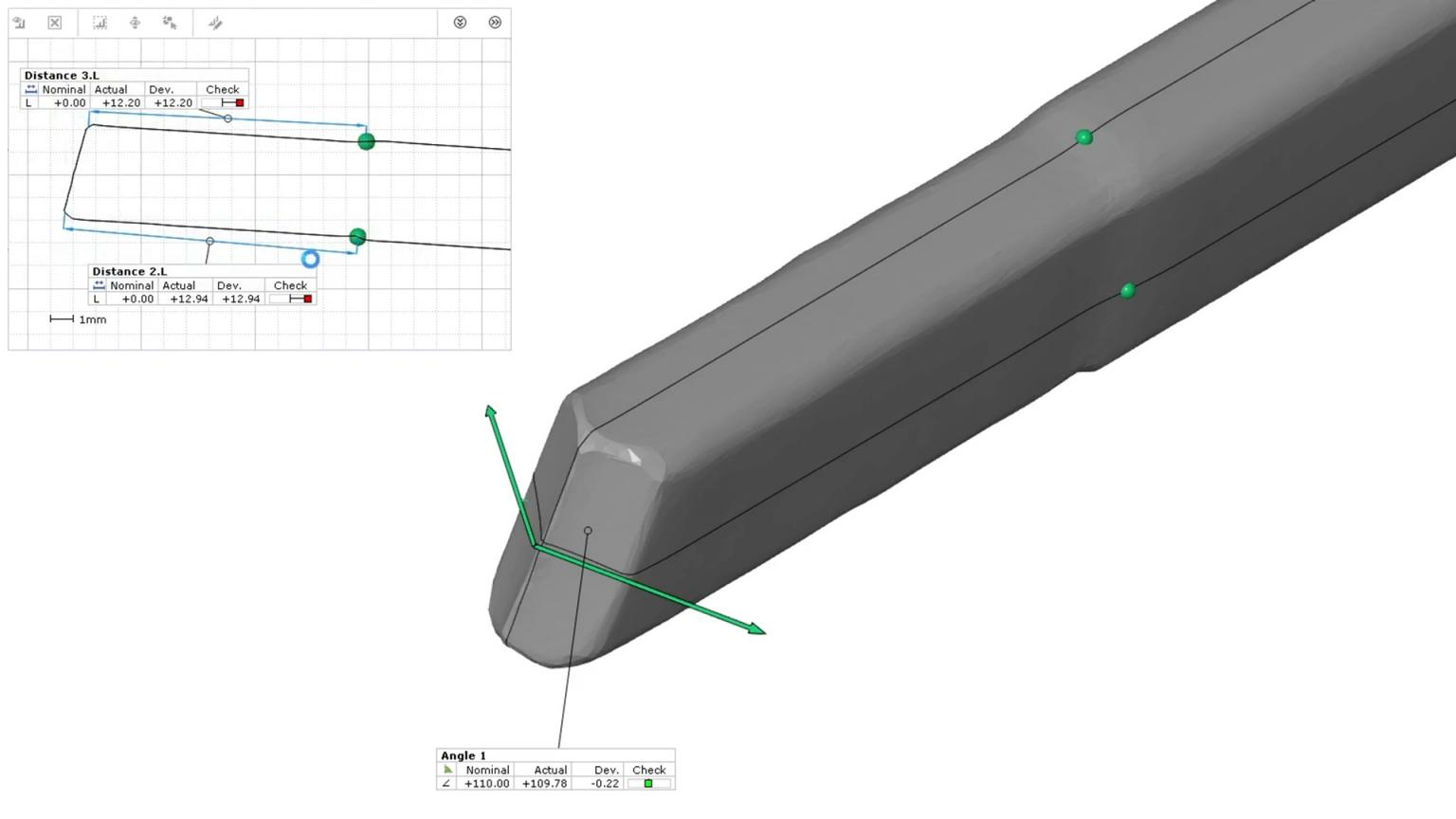

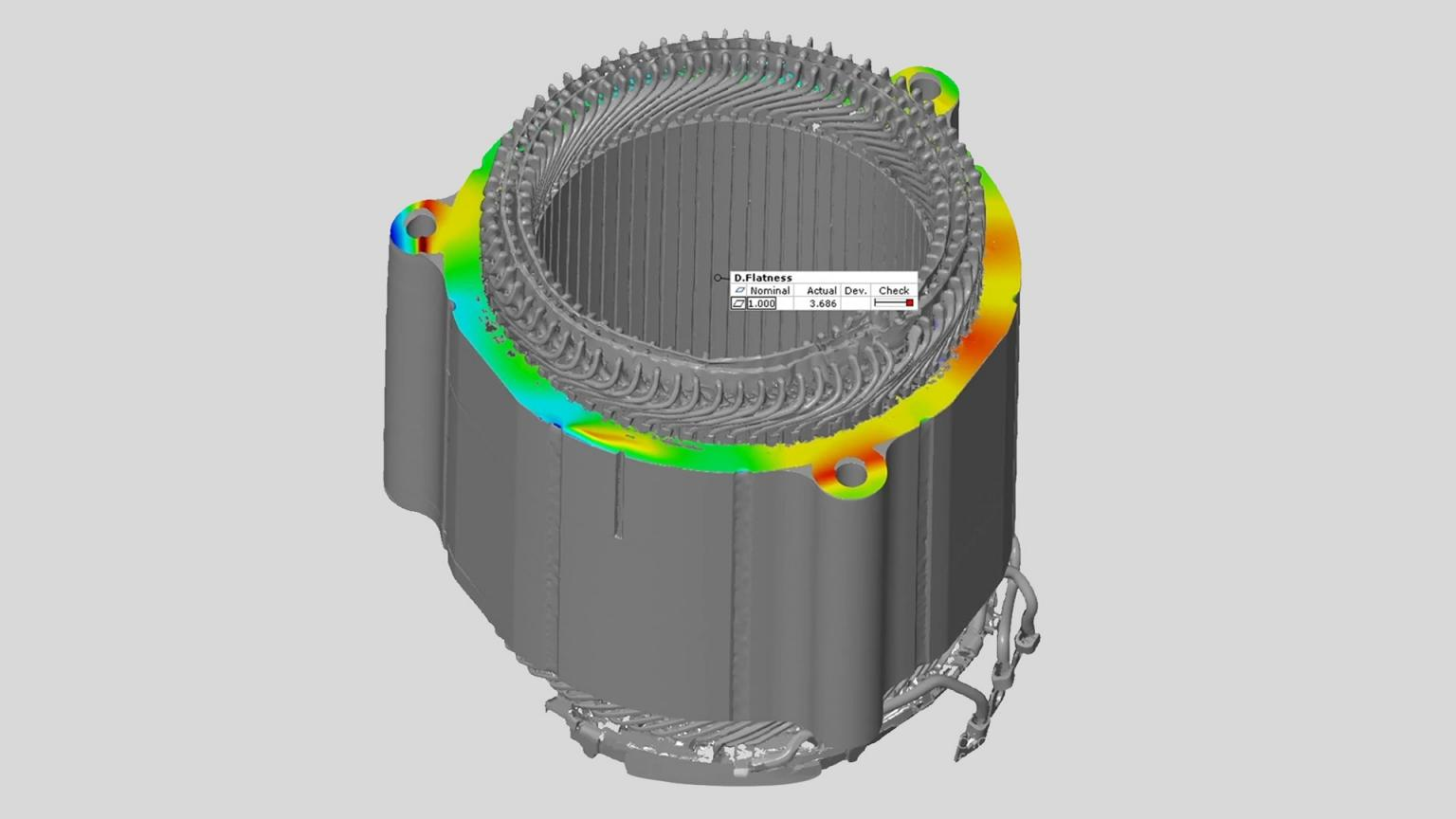

ZEISS ScanBox for eMotors specializes in the very fast and precise inspection and digitization of hairpins and stators. Both complete stators including hairpins as well as individual or multiple hairpins can be inspected fully automatically within a very short time. The recorded 3D measurement data is then visualized and evaluated in the powerful ZEISS INSPECT inspection software.

- Automated inspection

- Virual Measuring Room

- Analysis tool included

Automated inspection

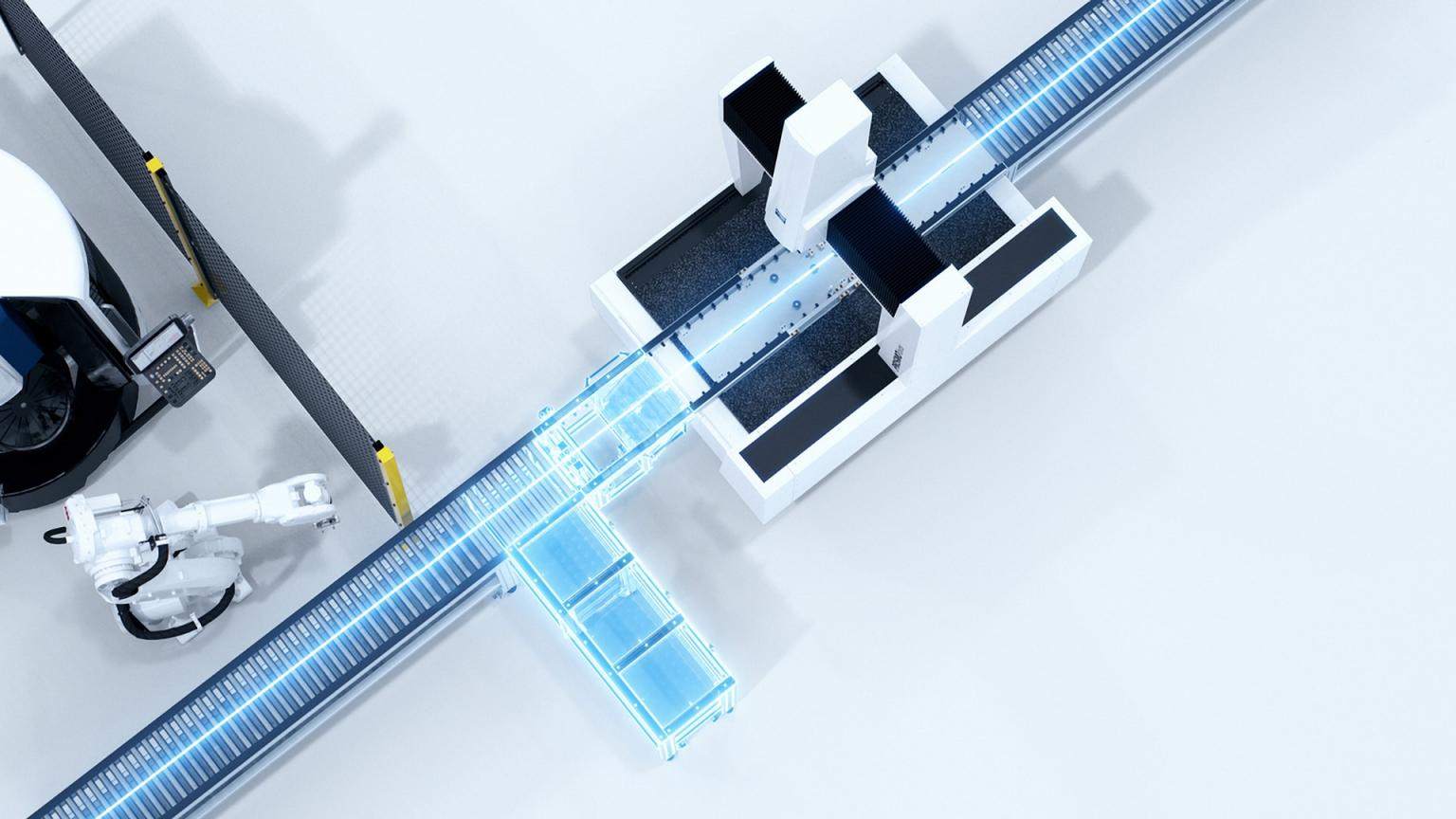

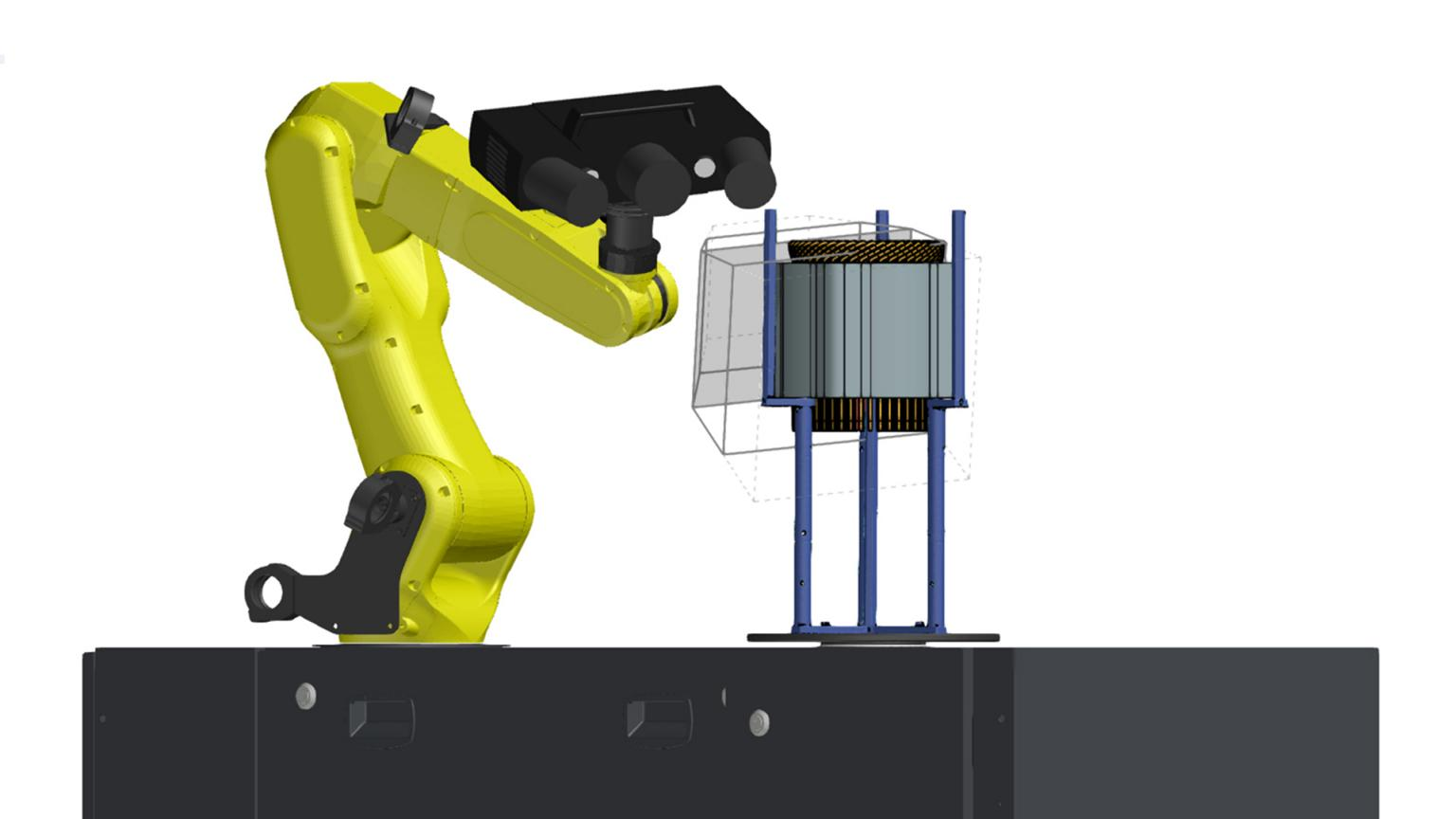

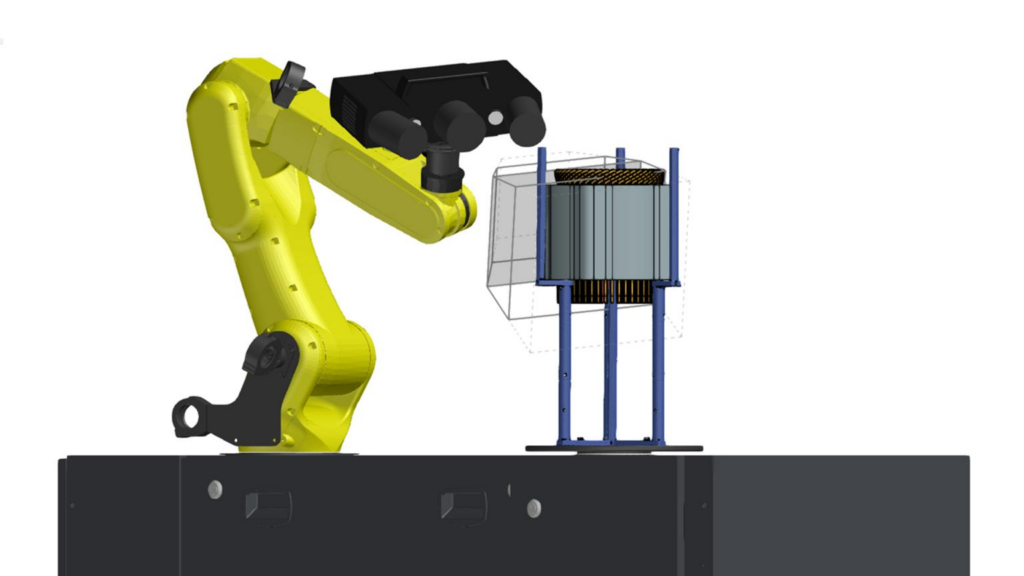

Programming, automated digitization, inspection and reporting are all included in the standardized measuring machine ZEISS ScanBox for eMotors.

The device is very intuitive to operate thanks to its user-friendly interface and the virtual measuring room (VMR) as the central control and measurement planning software.

Virual Measuring Room

The Virual Measuring Room (VMR) is the central control and planning software for the optical 3D measuring machine. This is where the real environment is mapped in a precise virtual simulation. The VMR contains a robot with sensor, enables the programming of the robot paths and the creation and execution of the measurement plan.

Thanks to the VMR, no special robot knowledge is required: all movements are simulated in advance and checked for collisions before execution.

Analysis tool included

WESTCAM offers everything from a single source: scanning, checking and reporting for detailed target/actual comparisons as well as shape and position tolerances. The easy-to-understand results enable you to implement any necessary corrections directly.

Carry out comprehensive analyses, create detailed reports and integrate the measurement results seamlessly into your existing processes.

Frequently asked questions (FAQs)

What is the function of the virtual measuring room (VMR) as a control tool for ZEISS ScanBox?

The ZEISS ScanBoxes feature the Virual Measuring Room (VMR) as the central control and planning software. This is where an exact reconstruction of the real environment takes place in a virtual simulation. The robot paths are programmed in the VMR, measurement positions are defined and the measurement plan is created and executed. Before implementation, all movements are checked for safety using simulations, without the need for special knowledge.

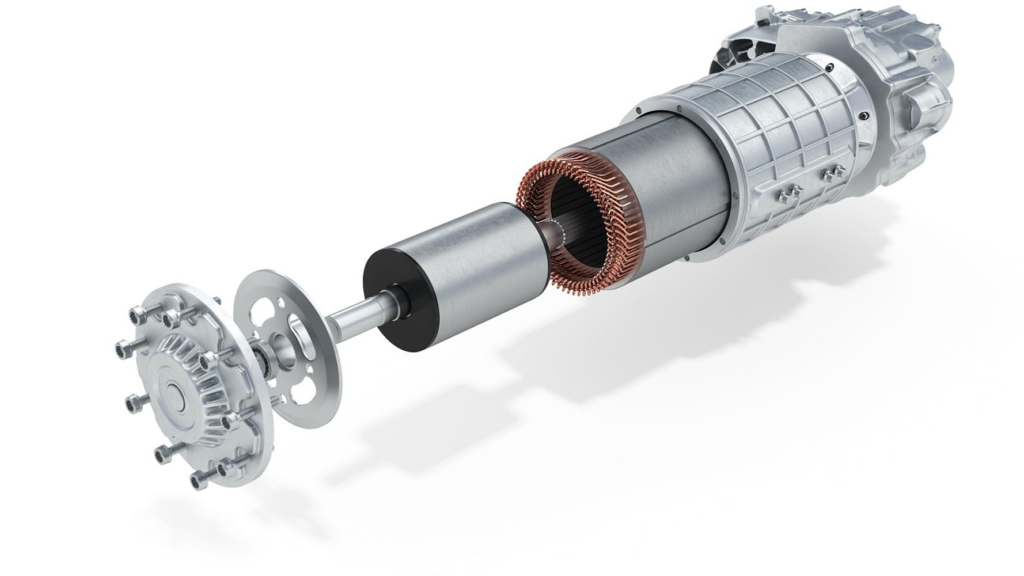

What are the features of the ZEISS ScanBox for eMotors?

With the ZEISS ScanBox for eMotors, complete stators including hairpins or single/multiple hairpins can be inspected and digitized very quickly and precisely. The fully automatic inspection takes place in a short time and the collected 3D measurement data is recorded.

How can the ZEISS ScanBox for eMotors be used for the quality assurance of eMotors?

The ZEISS ScanBox is a standardized, optical measuring machine that enables automated digitization, inspection and reporting. The system can be used to analyze form and position tolerances and perform detailed target/actual comparisons. In addition, the ZEISS INSPECT software enables specialized evaluation options for hairpins and stators in order to efficiently incorporate process optimizations into production.

We advise you personally!

Gladly there for you

Mechatronics & Robotics

Mechatronics & Robotics