Feature/macro programming

With hyperMILL feature and macro technology, you can optimize your CAM programming through standardized and automated processes.

The feature and macro technology allows you to minimize the programming effort for repeated geometries such as holes, pockets, threads etc. and prevents errors – while at the same time allowing you to establish standards for machining in your company!

This has the great advantage that you not only program faster and with greater process reliability – you also guarantee optimum and consistent machining thanks to the consistent machining processes!

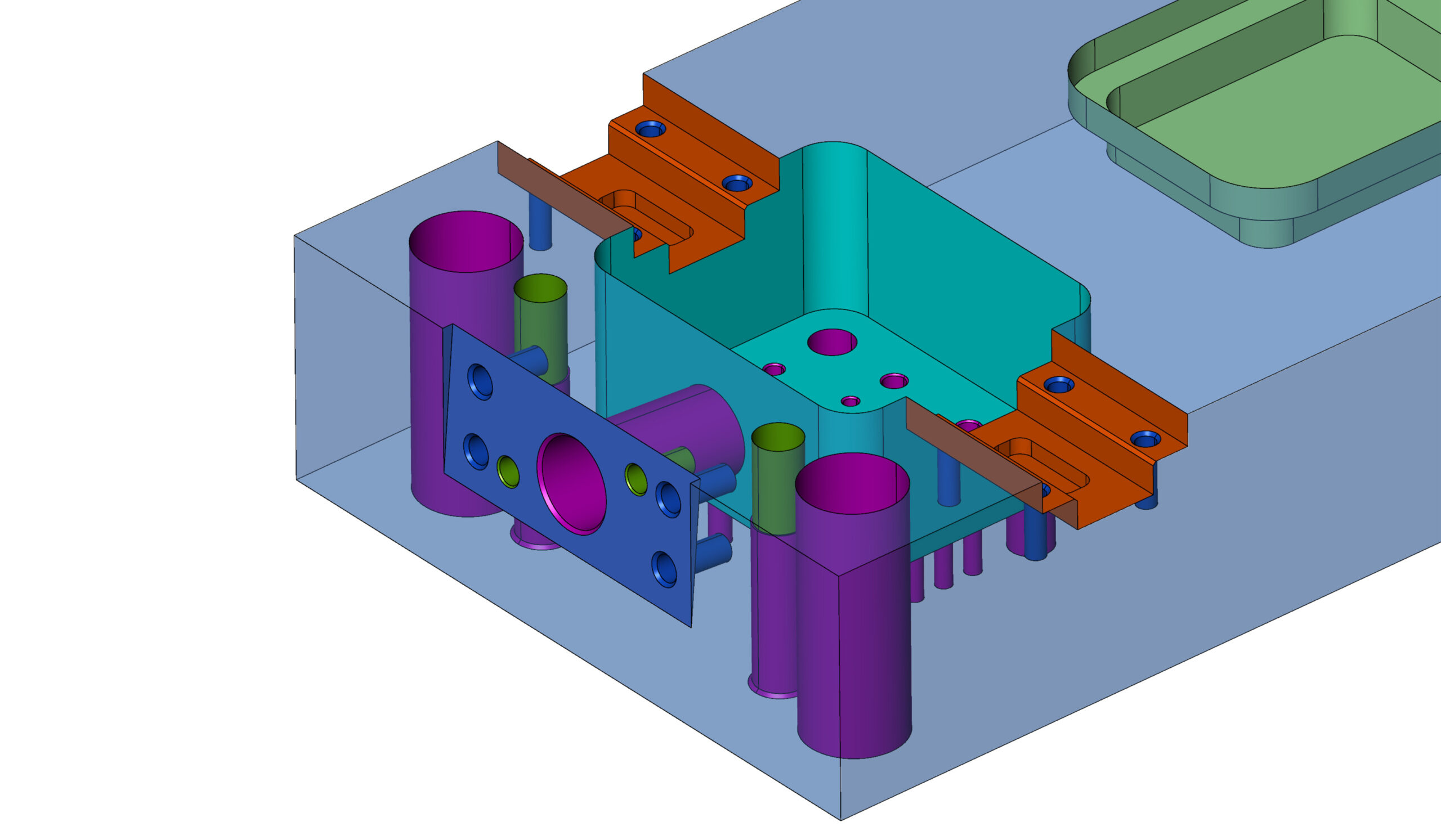

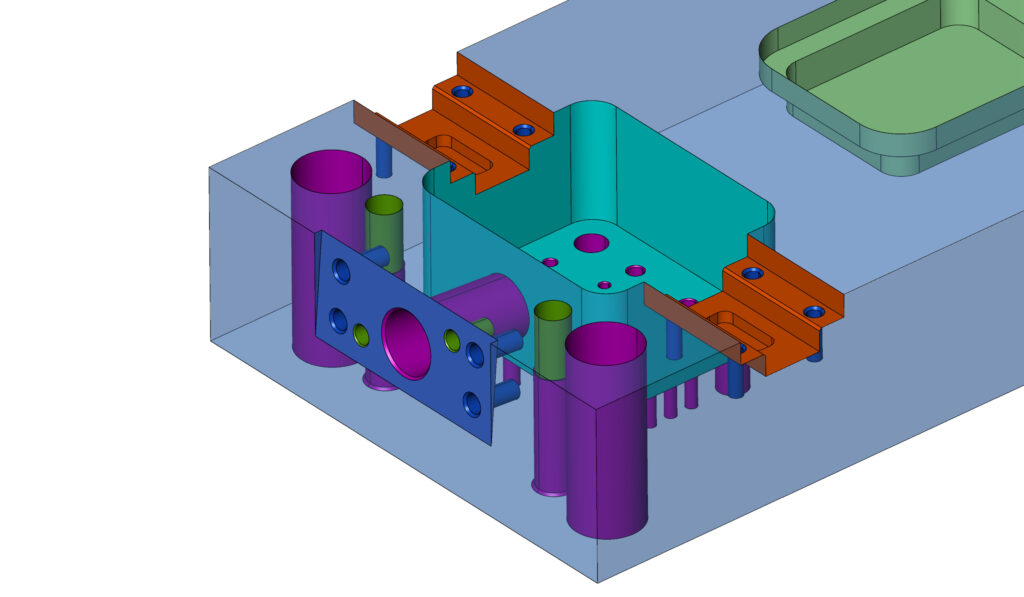

- Feature detection on all components

- Efficient CAM automation with intelligent macros

- Color tables for feature recognition

- Intelligent macros for flexible customization

Feature detection on all components

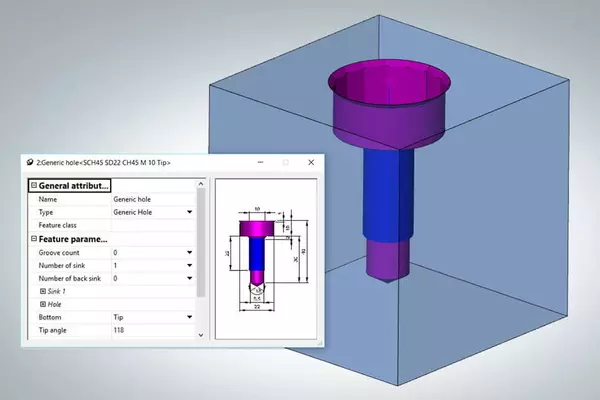

hyperMILL‘s feature recognition automatically identifies characteristic geometries such as holes, threads and pockets – regardless of whether these geometries were created in hyperMILL or the part was imported via an interface.

These features can be provided with additional information for machining. Automatic feature recognition makes this geometry information usable for CAM programming, which means that this information no longer needs to be selected by the CAM user.

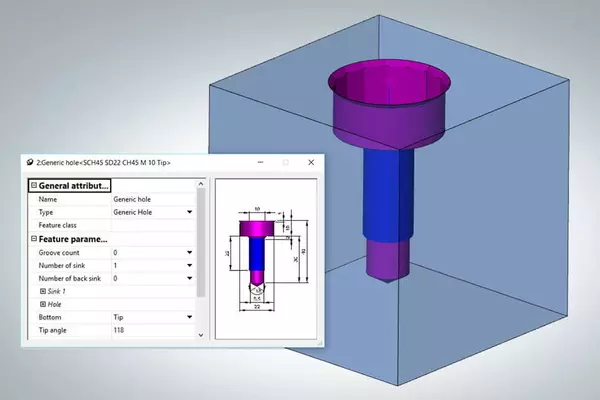

Efficient CAM automation with intelligent macros

Processing steps (intelligent macros) can be created for recognized features/geometries. These macros save proven processing strategies and user-specific settings that can be automatically reapplied to the geometries (features) present on this component at any time if required.

This significantly reduces manual programming time and standardizes your processes!

Color tables for feature recognition

A unique aspect of hyperMILL feature recognition is the use of color information to identify and classify geometries. By using color tables, features such as fits, tolerances and specific machining requirements can be visually coded directly in the CAD model.

This enables the correct machining strategies to be assigned quickly and precisely during CAM programming and significantly improves the accuracy and efficiency of the processes.

Intelligent macros for flexible customization

hyperMILL‘s intelligent macros make it possible to define rules and conditions for each machining step. Based on these rules and the geometry information such as diameter and depth, the machining steps are automatically adapted to the current requirement and the required tool is selected from the database.

This makes the creation and customization of macros simple and efficient, and created macros can be applied to a variety of different geometries.

Advantages of hyperMILL feature and macro programming

Reduce manual intervention and minimize programming errors with standardized processes.

Use color information to quickly identify and classify processing features.

Optimize your production processes with automatic adjustments and intelligent feature recognition.

Macros ensure repeatable processing results.

Automated processing steps significantly reduce the programming time.

Frequently asked questions (FAQs)

How does feature recognition work in hyperMILL?

Automatic feature recognition identifies geometric features such as holes, pockets and threads from solid and surface models and makes them usable for CAM programming.

What are intelligent macros in hyperMILL?

Intelligent macros are ready-made machining strategies based on defined rules. They automatically adapt to the geometry information and select the appropriate tools and processing steps.