ZEISS INSPECT Correlate

Dynamic 3D analysis made easy.

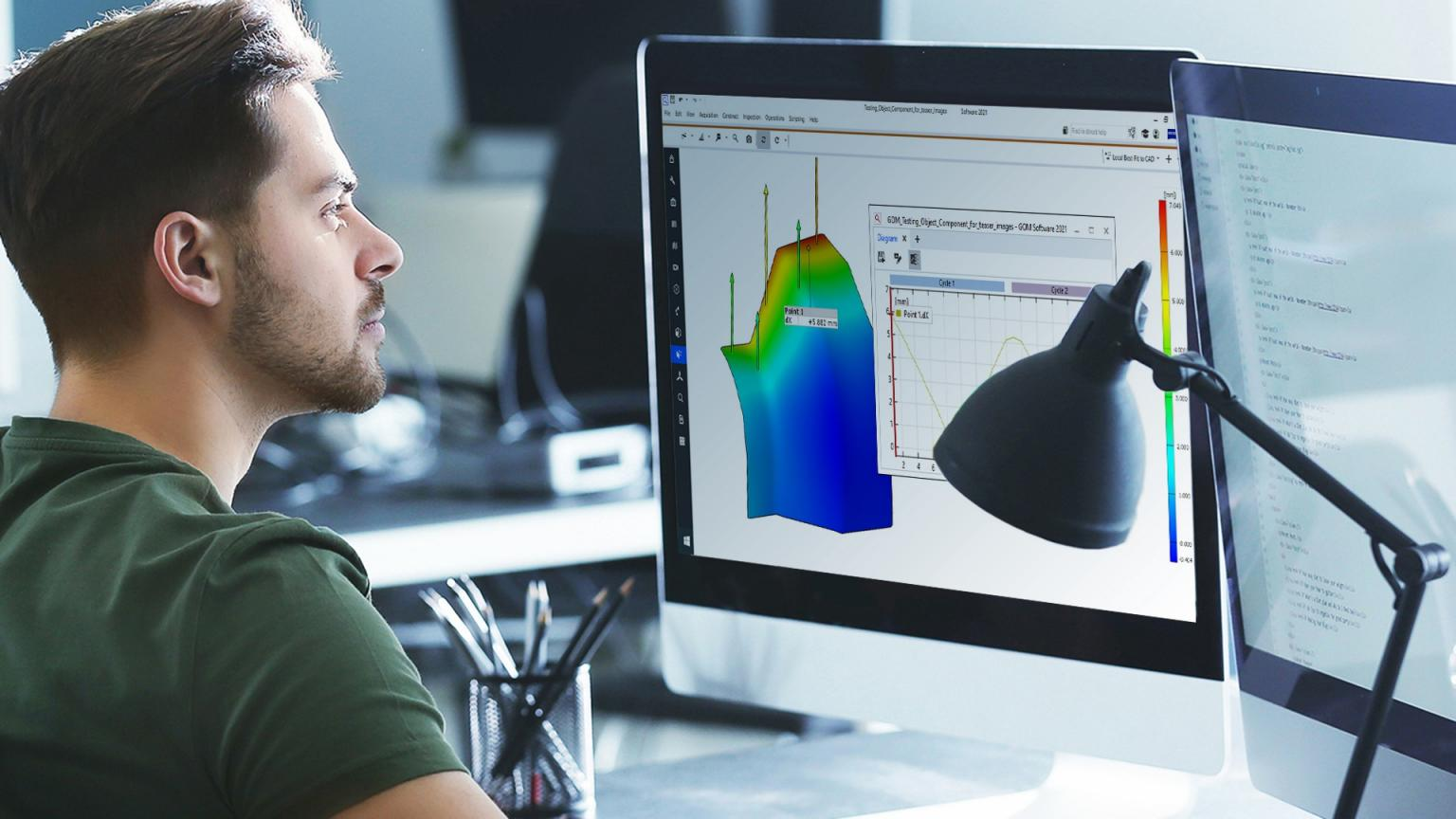

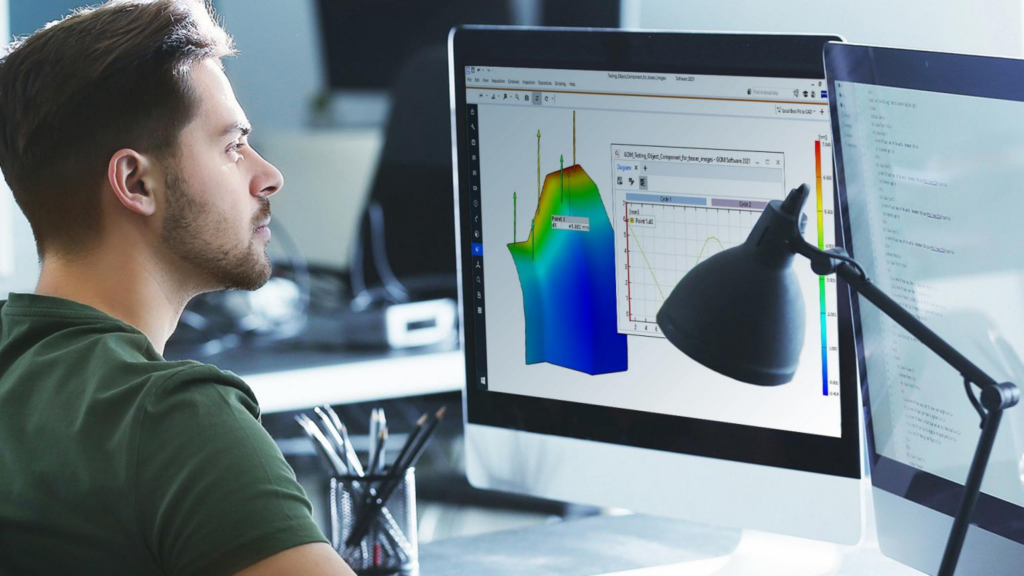

Turn videos into meaningful measurement data. With ZEISS INSPECT Correlate you can analyze dynamic processes such as displacements, rotations or angle changes. Intuitive to use and equipped with practical functions, the software provides you with optimum support for your 3D inspection tasks.

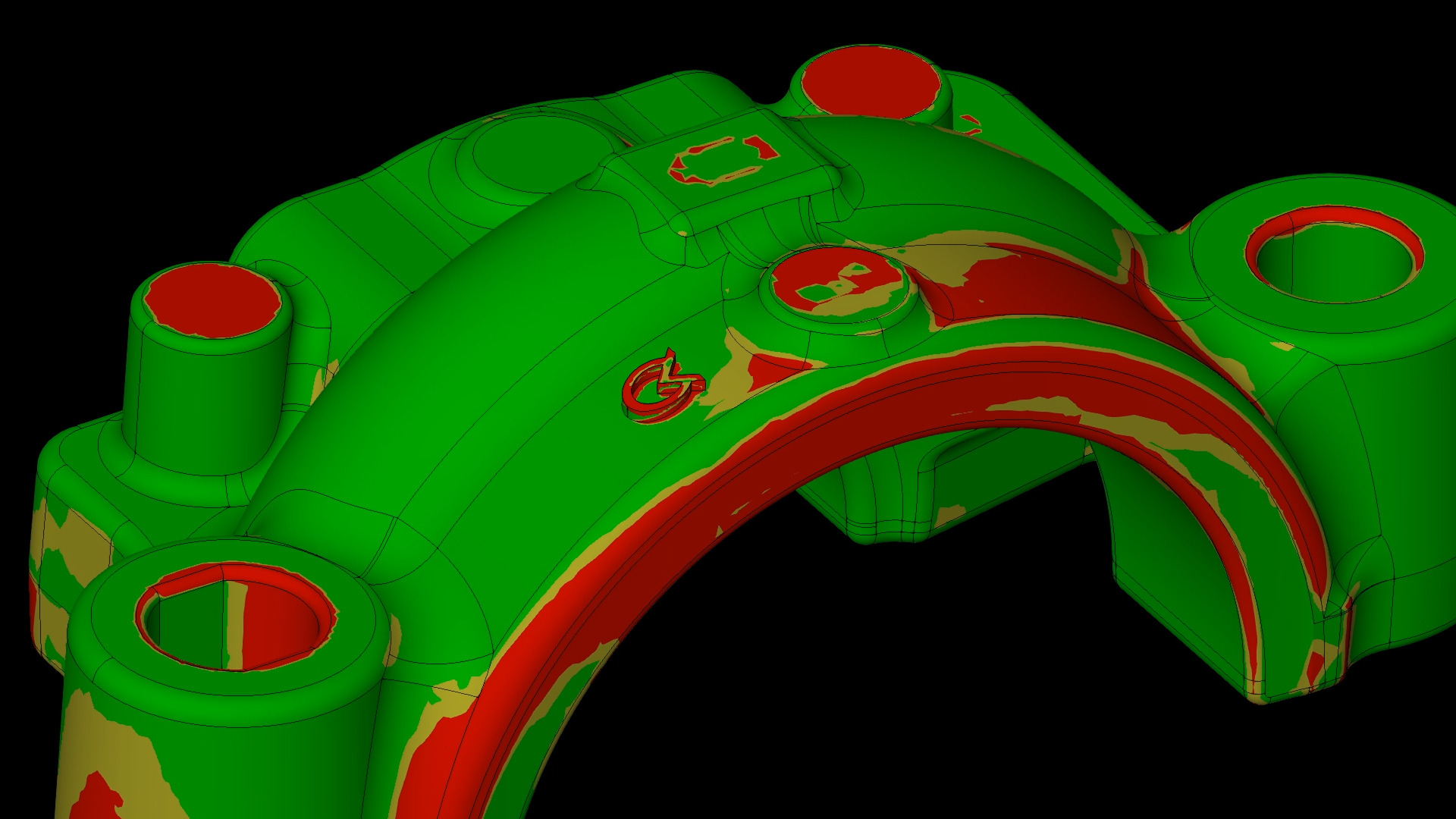

Use digital image correlation and point tracking algorithms to measure 3D coordinates with sub-pixel accuracy and track them over time.

- 2D analyses

- 3D analyses in conjunction with ARAMIS system

- Analyze dynamic processes

- Integrated reporting functionality

- Automatic processes for recurring evaluations

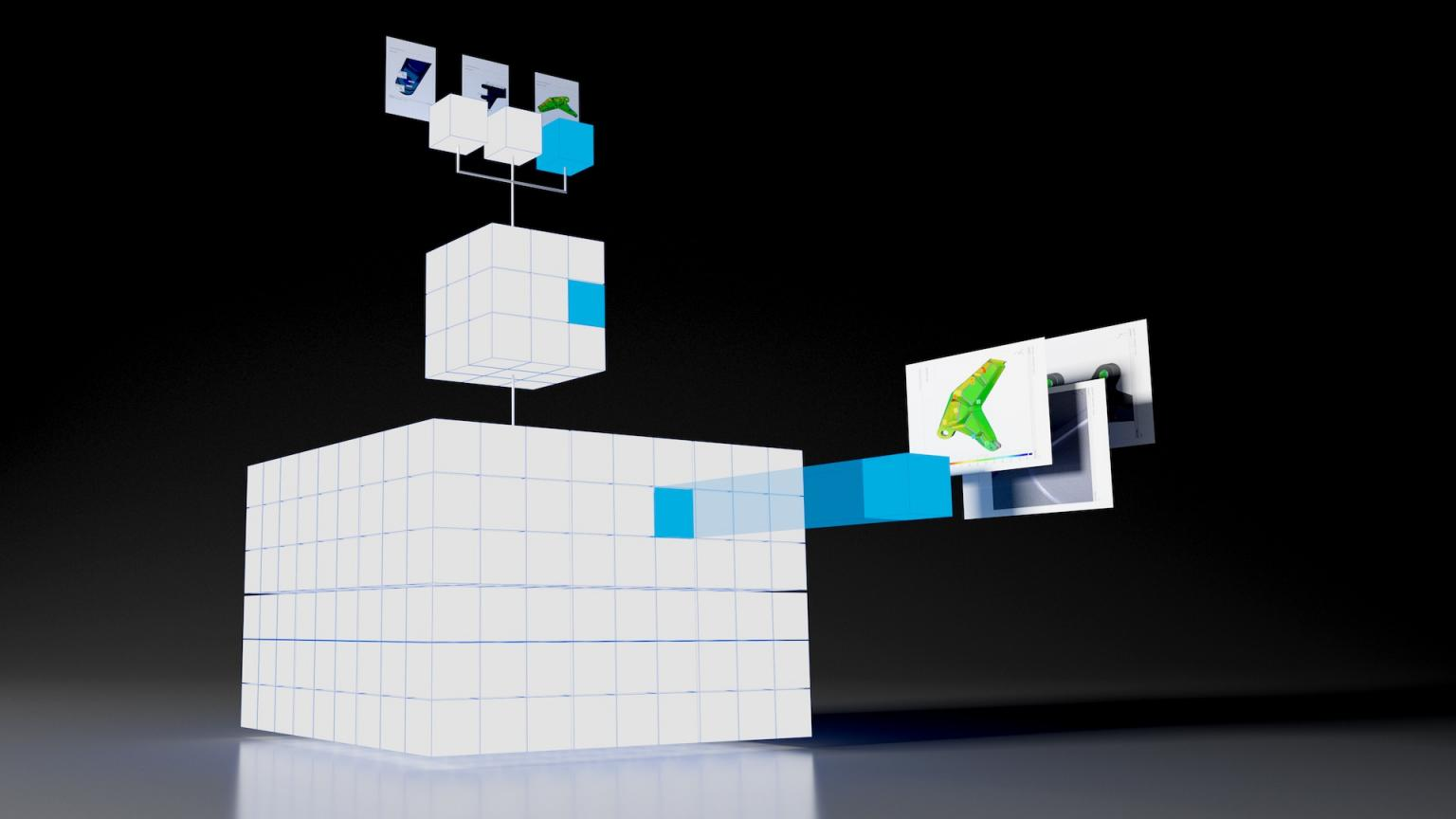

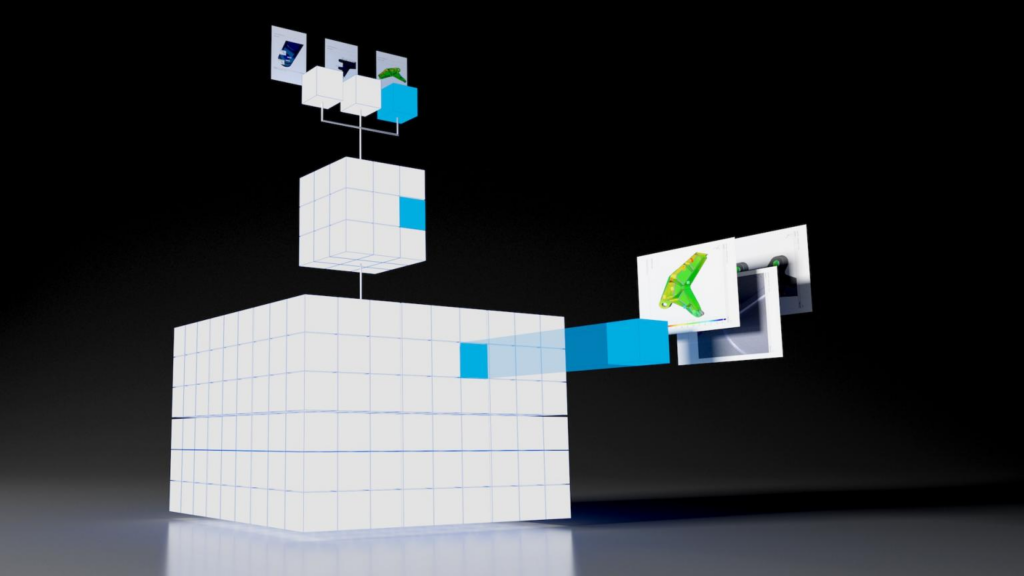

Save inspection steps

As ZEISS INSPECT Correlate saves all evaluations, result variables and dependencies in the background, reports can be updated and new results generated with just a few clicks.

Alignments and reference systems are easily created, tracked and adjusted. Simply create a project template with which you can evaluate an entire series.

Special features

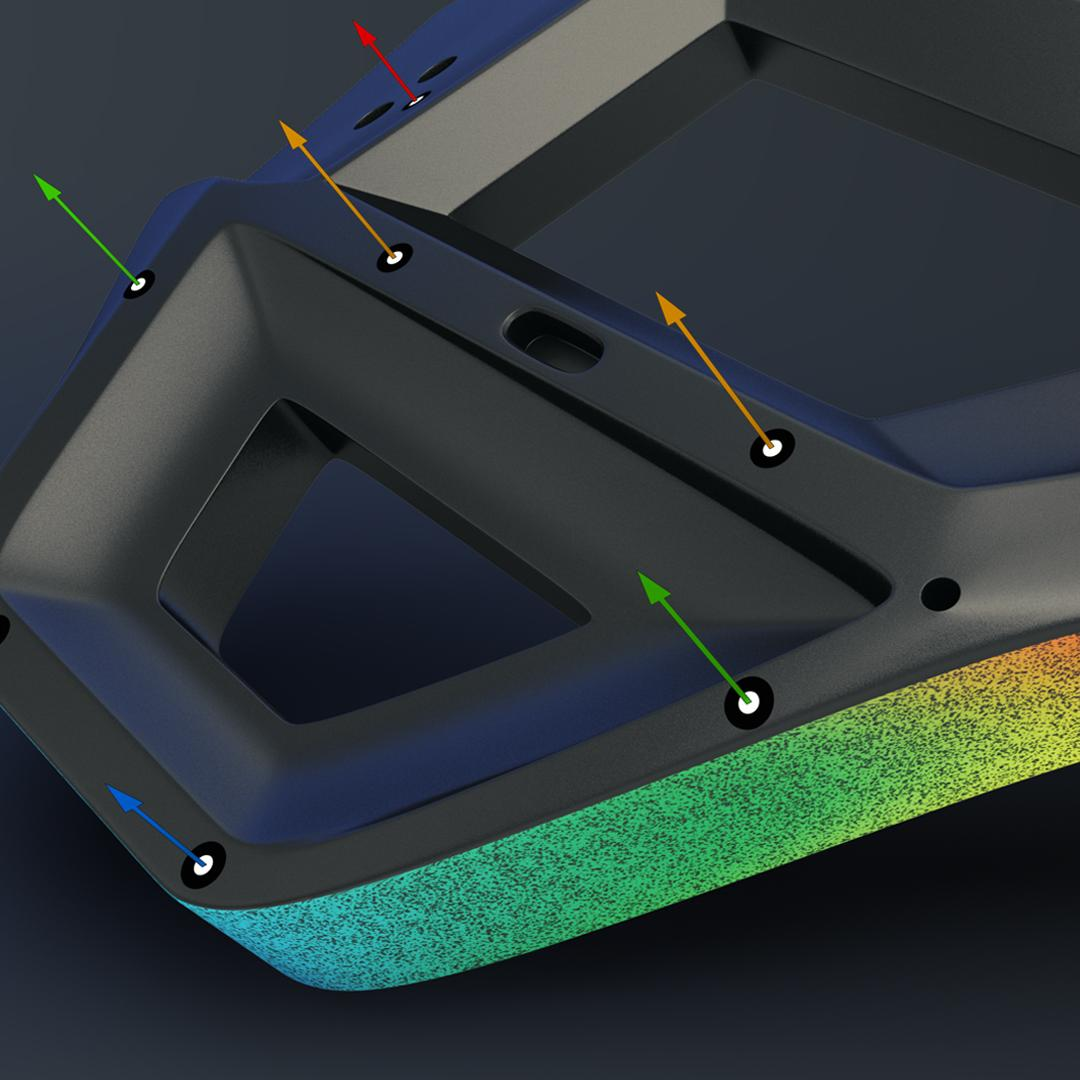

ZEISS INSPECT Correlate offers precise evaluation functions such as 6DoF analysis, trajectory determination and virtual extensometers. It supports CAD and FEM import as well as the measurement of control geometries with probes and adapters.

The software is compatible with generic USB3 cameras, high-speed cameras, ARAMIS sensors and photogrammetric solutions. Thanks to the Python interface, all operations can be recorded, edited and reused for automated evaluations.

Adapt to your working style

Do you need additional functions? Customize ZEISS INSPECT Correlate exactly to your needs with special apps.

The available apps offer functional enhancements such as the determination of material parameters from tensile, Nakajima and bulge tests, the import of FEM data sets for the full-surface comparison of measurement and simulation data and thermomechanical deformation analysis using temperature data from thermographic cameras.

Frequently asked questions (FAQs)

How can ZEISS INSPECT Correlate help with the investigation of movements?

ZEISS INSPECT Correlate enables the precise analysis of movements using digital image correlation and point tracking algorithms. These technologies break down videos into detailed measurement data so that displacements, rotations and angular changes can be examined precisely, even if they are only minimal. For example, the deformation of a component during a crash test or the elongation of a material under load can be tracked in detail.

Which cameras and data types can ZEISS INSPECT Correlate work with?

ZEISS INSPECT Correlate is compatible with a wide range of cameras, including USB3 cameras, high-speed cameras, ARAMIS sensors and photogrammetric solutions. Regardless of the camera used, the software ensures optimal results. In addition, ZEISS INSPECT Correlate supports various data types, including CAD and FEM datasets, allowing measurements to be seamlessly integrated into existing design and simulation models.

What else can the additional apps for ZEISS INSPECT Correlate do?

The additional apps for ZEISS INSPECT Correlate enhance the software with many useful functions for material analysis. For example, these apps can be used to determine material parameters from tensile, Nakajima and bulge tests. They also enable the comparison of measurement and simulation data across the entire surface using FEM imports. Thermo-mechanical deformations can also be analyzed using thermographic cameras.

We advise you personally!

Gladly there for you