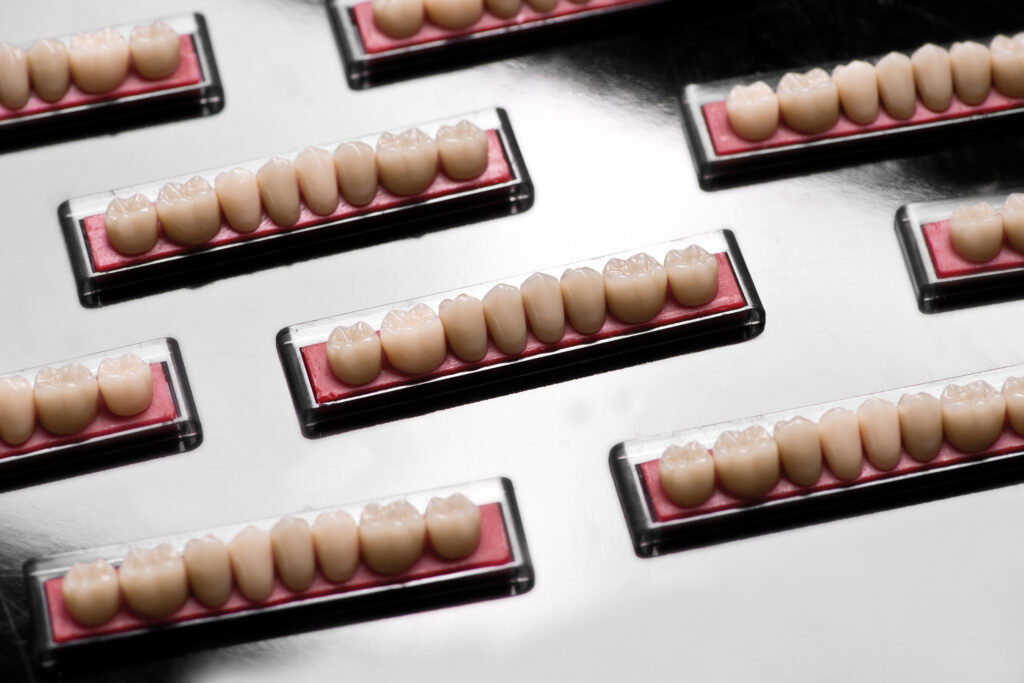

Production moulds for acrylic teeth (oder denture teeth)

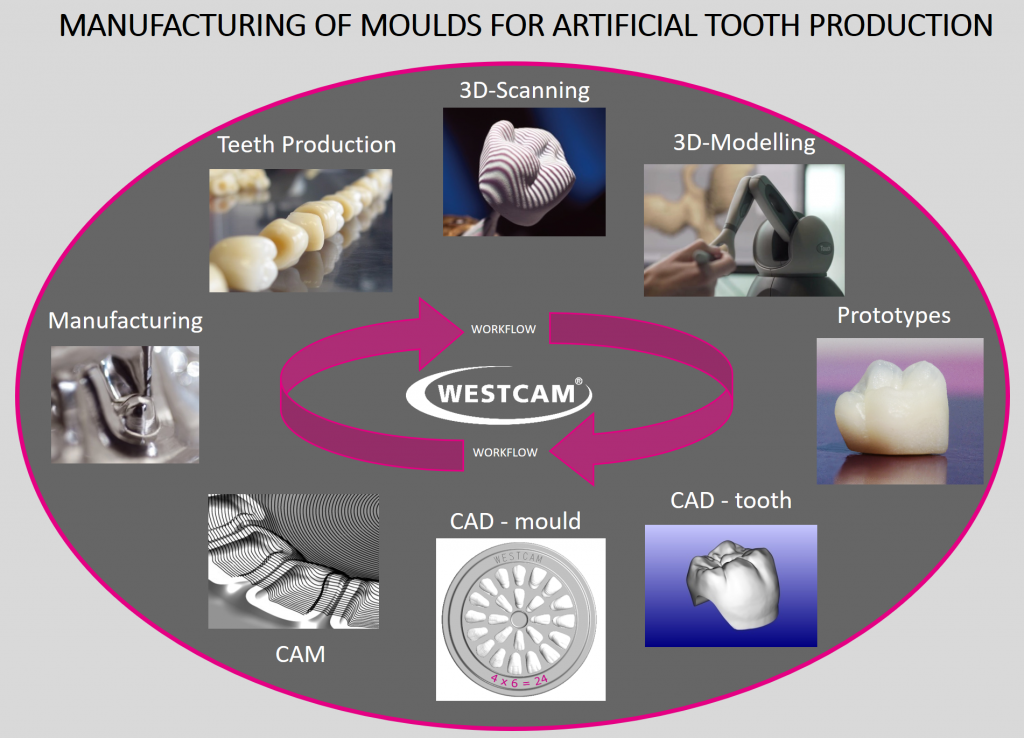

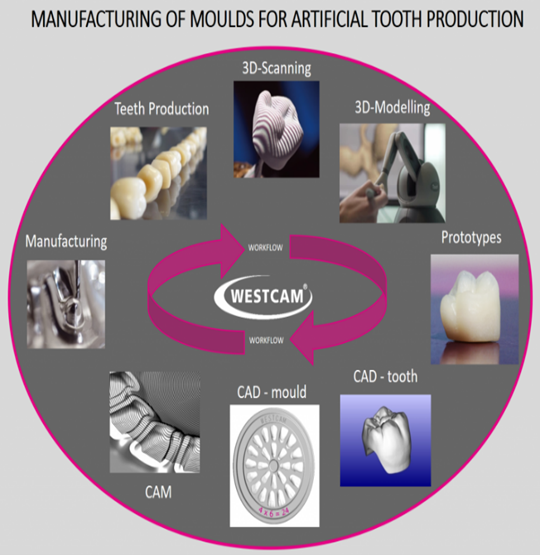

Mold making by WESTCAM

Would you like to renew your production mold fleet? Do you need support for the production of new tooth lines? Great, then you’ve come to the right place!

More than 20 years of experience in the development and design of production molds for the manufacture of artificial teeth (modul manufacturing).

We get your teeth in perfect shape!

- Over 20 years of dental expertise

- Individually adapted to your production process

- Engineering & production of molds from a single source

- High-precision molds in a short time

- Long service life of the molds

- Result: Teeth with high accuracy and very thin flash

- Reproductions: quick & uncomplicated

- Discretion & strict confidentiality

Tailor-made for your production process

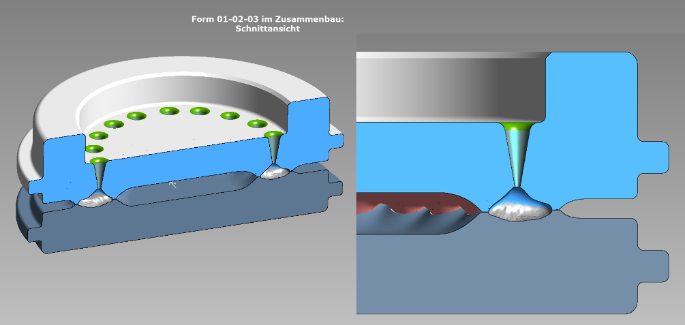

We always engineer and manufacture the production molds for denture teeth individually.

By using state-of-the-art technologies, we ensure an end-to-end digital process chain with which high-precision production molds can be manufactured in a short time.

These molds can be used directly in production and are characterized by their long service life!

3 to 4 times longer service life than conventional electroforms!

High quality material

The molds are made of high-quality stainless mold making steel (DIN 1.2083), are hardened to up to 54 HRC and supplied in highly polished quality incl. 100% quality control (3D measurement, measurement protocol TARGET/ACTUAL comparison).

Let’s go – new CAD/CAM molds

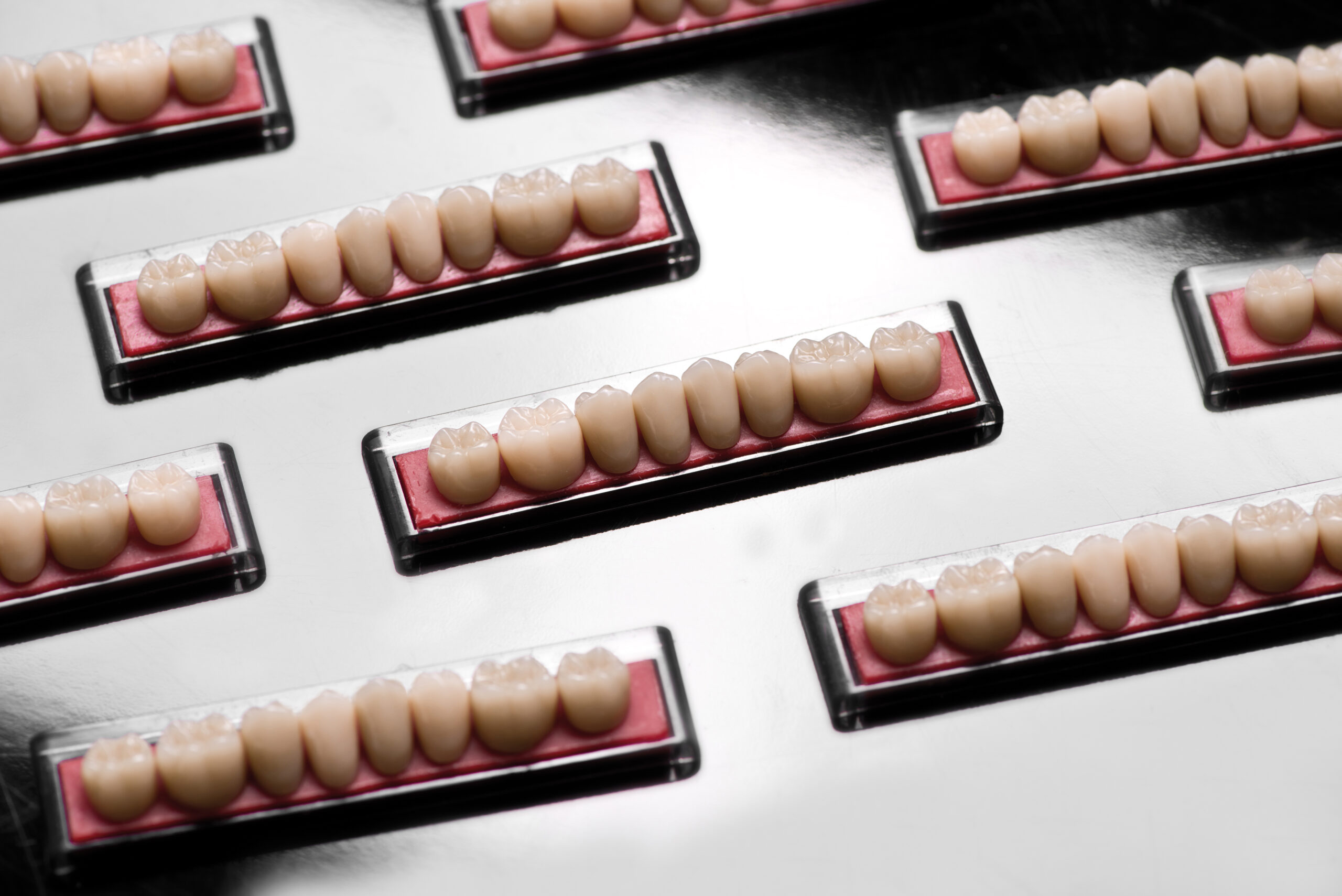

Their new CAD/CAM molds can be used immediately after production and are characterized by excellent accuracy of fit and an extremely sharp parting edge.

Our molds are used to produce teeth with an impressively high level of detail and an extremely thin press burr, meaning that only minimal manual reworking is required.

Sorting and plugging by WESTCAM

Refinement by means of a trowalizing process is sufficient to subsequently sort the teeth by means of a TSB – tooth sorting system to separate and sort the teeth.

In the subsequent process, the teeth can be fixed with our TMM – tooth insertion unit onto wax carrier plates.

Your data in trustworthy hands

We know that design data is one of your most valuable production factors. That’s why we keep customer data strictly confidential and archive it securely.

If required, we can quickly create exact copies of already manufactured production molds with your help.

From the design to the laser-engraved CAD/CAM production mold

We are also happy to help you convert your electroplating molds to modern CAD/CAM molds. The advantage is obvious: CAD/CAM molds have a 3 to 4 times longer service life than conventional electroforming molds.

Frequently asked questions (FAQs)

What material is used for the tooth molds?

The molds are made from high-quality stainless mold steel (DIN 1.2083). They are hardened up to 54 HRC and supplied in highly polished quality including 100% quality control (3D measurement, measurement protocol TARGET/ACTUAL comparison).

Why should I convert my old molds to CAD/CAM molds?

The WESTCAM CAD/CAM molds can be produced in a short time, can be used immediately in production and have a service life that is 3 to 4 times longer than conventional electroforming molds.