Materialise e-Stage for Metal+

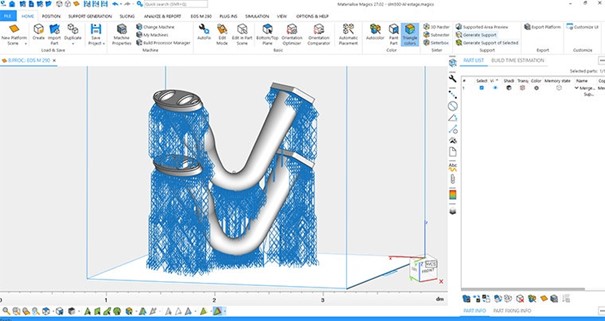

Success in 3D metal printing means keeping costs low, production quality and efficiency high and printing designs error-free the first time. With e-Stage for Metal+, you can create supports completely automatically.

This brings advantages from data preparation to the removal of supports.

- Automatic generation of support structures

- Open support structures

- Stacking components in the Z direction

Automatic generation of support structures

Automatic generation of supports and placement of additional cones to reduce slag formation and stresses and prevent possible deformations.

Save up to 90% of your time for the manual generation of supports and at the same time minimize the risk of manual errors and damage to the construction part.

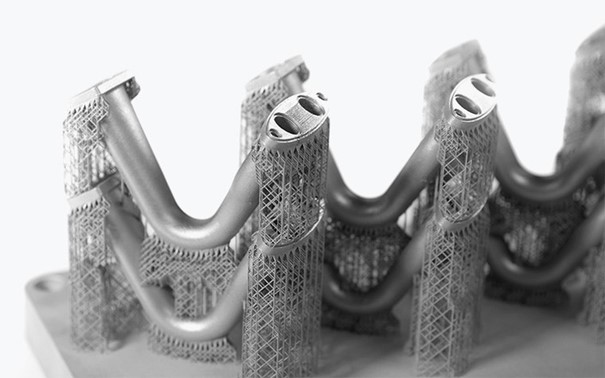

Open support structures

Optimize your post-processing process with the help of fine supports that you can easily remove, reducing the need for additional processes such as EDM and machining.

For large components, material savings of up to 40% can be achieved compared to block supports, while improving the accuracy and quality of the parts. The easy-to-remove, ultra-thin contact points and the fine support structure mean that almost 100% of excess powder can be removed, reducing risks to the health and safety of your employees.

Generate only required supports to significantly reduce post-processing time compared to traditional support generation methods.

With e-Stage for Metal+, you can determine exactly where supports are needed so you can print right the first time without wasting material or time removing unnecessary structures.

To make efficient use of your build volume, e-Stage allows you to nest parts on top of each other in the Z-direction so that your machine can run longer during non-productive times.

Frequently asked questions (FAQs)

Which coater blades should be used?

The E-Stage support is very thin and can be deformed by hard blades such as steel blades. We recommend flexible blades such as rubber blades.

Can e-stage support be combined with conventional support structures?

In principle, the E-Stage Support is sufficient to adequately support the components. If a stronger connection is required, the E-Stage Support can be combined with Cone Supports.

Which components are particularly suitable for E-Stage Support?

In general, all components can be supported quickly and automatically with E-Stage. The greatest advantages are found in components with particularly complex geometries, with internal geometries and in components that are manufactured from expensive materials such as titanium.