Fusion Manufacturing Extension

Especially for sheet metal-based nesting and manufacturing as well as metal-based additive manufacturing

Autodesk Fusion Manufacturing Extension has numerous additional features that have been specially designed to support production companies.

These tools enable you to make optimum use of your machines and devices for metal additive manufacturing, CNC machining, nesting and sheet metal part production.

- Automatic CNC machining

- Nesting of several plans

- 3D printing simulation

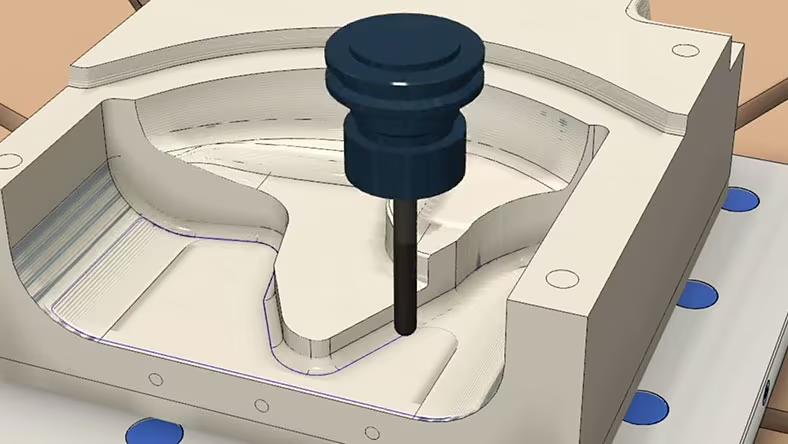

Automatic CNC machining

You can program complex and detailed components with intelligent whole-part strategies such as steep and flat areas, deburring, hole detection and turning.

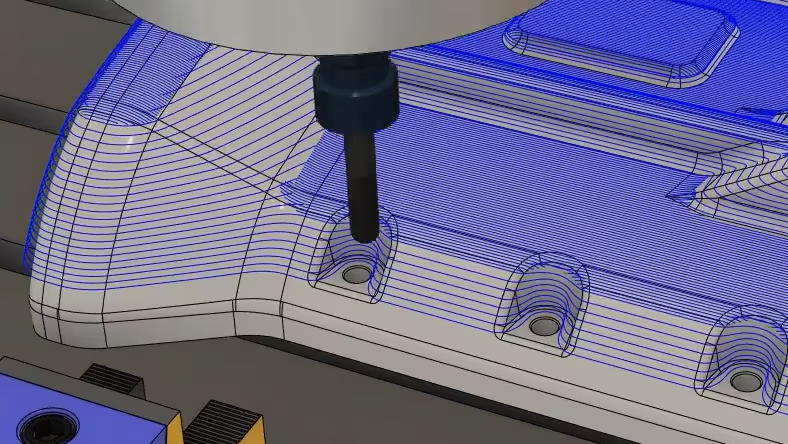

Nesting of several plans

In order to obtain an overview of prices, quotations and orders, intelligent nesting groups workpieces according to their thickness and other material-specific parameters.

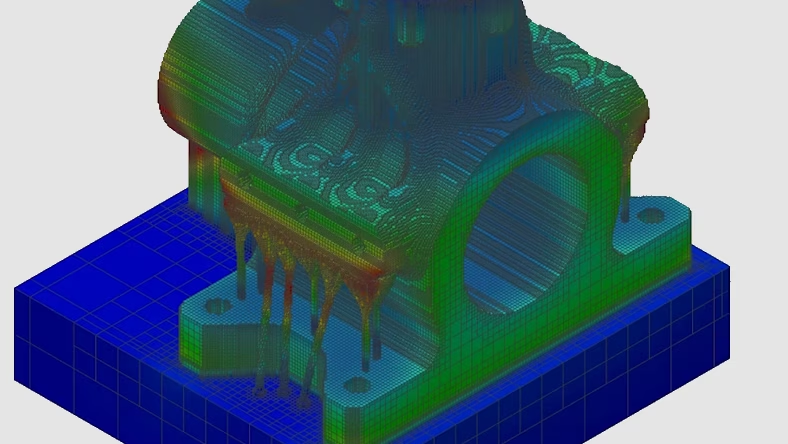

3D printing simulation

Use thermal simulation tools to validate the 3D printing process. In this way, you can avoid costly errors and immediately obtain higher quality workpieces.

Discover more extensions

Unlimited number of calculations in the cloud for generative design, FEM, electronic cooling or even injection molding. Easily optimize your designs and the behavior of your components.

Automate complex geometries to improve the behavior and design of your products.

Especially for the optimization of your PCB designs and analysis of electromagnetic behaviour. The impedance of each critical transmission line can also be controlled.

Change requests, version management or even automatic order list numbering and parts list management can be adapted easily and efficiently.

Frequently asked questions (FAQs)

What special functions does Fusion Manufacturing Extension offer?

The Fusion Manufacturing Extension offers advanced functions for metal-based additive manufacturing, CNC machining and the nesting and production of sheet metal parts.

How can the Manufacturing Extension improve my production processes?

The extension helps to automate repetitive tasks, reduce errors and speed up the transition from design to manufactured component.

Mechatronics & Robotics

Mechatronics & Robotics