Fusion

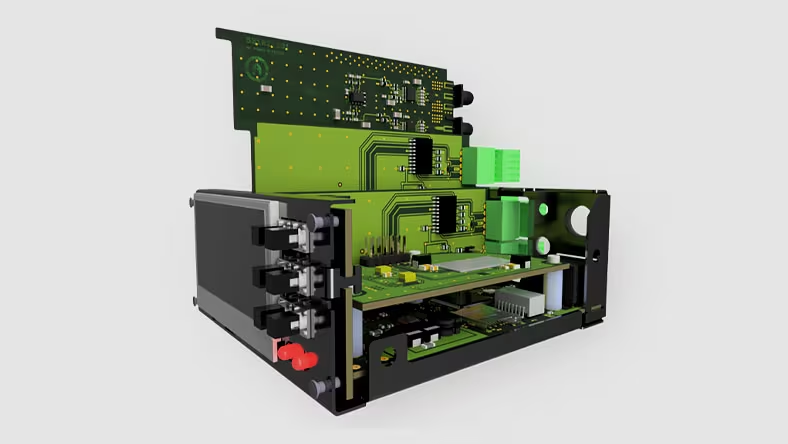

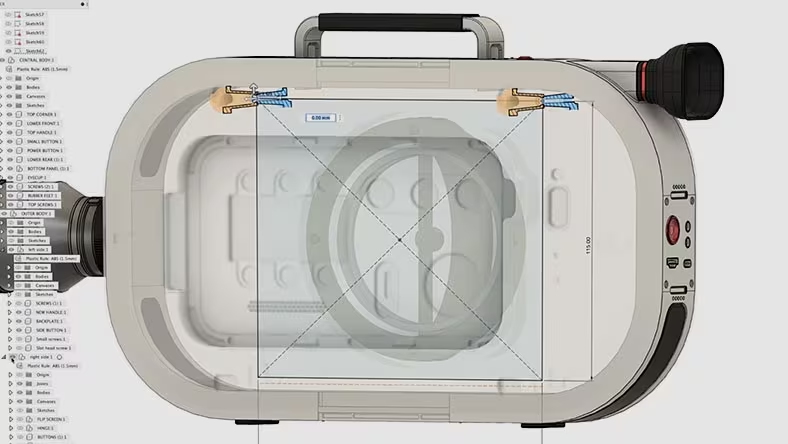

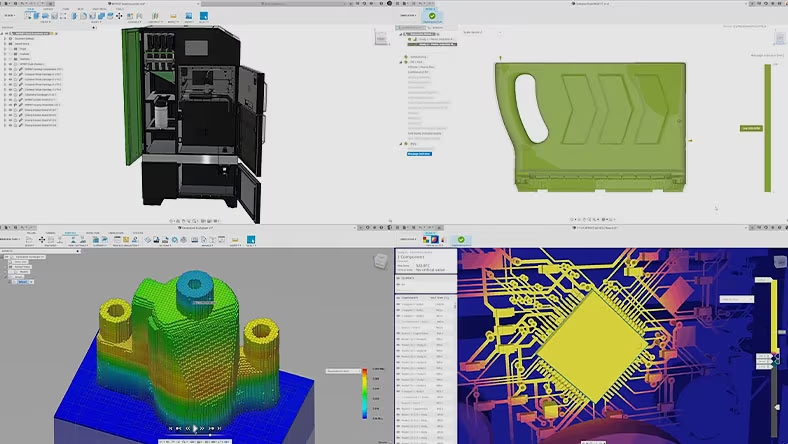

Modeling, CAD, CAM, CAE and PCBs in 3D for product design and fusion manufacturing are available on the cloud-based software platform.

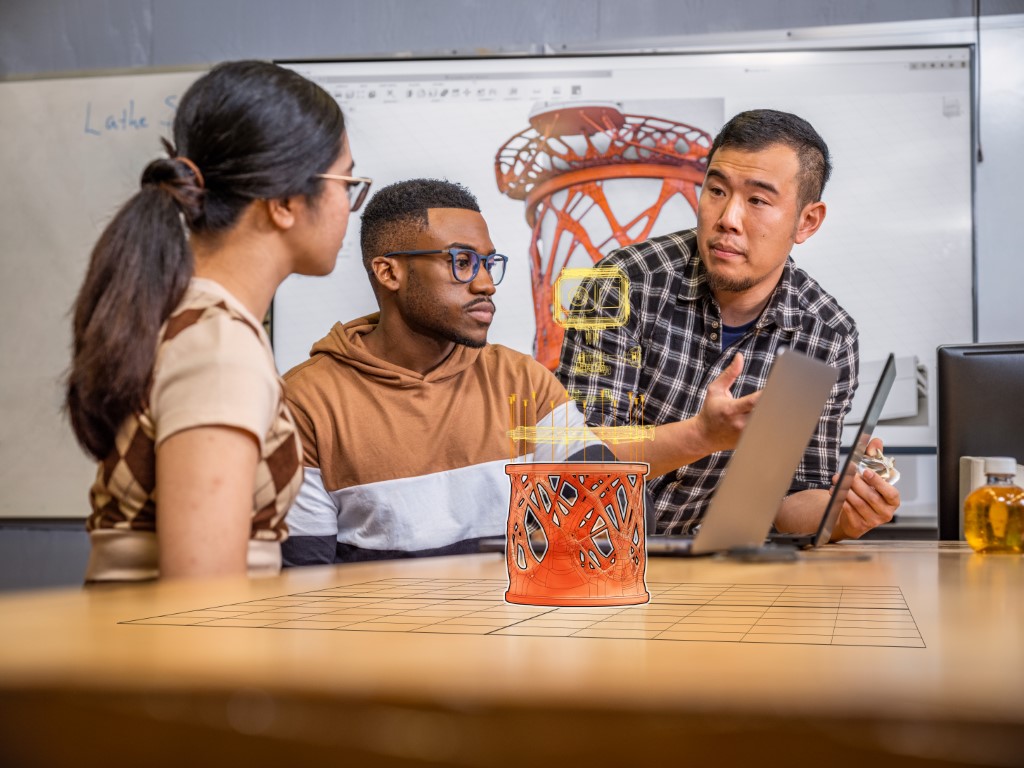

Experience the future of construction and manufacturing technology with Fusion, formerly Fusion 360. This platform enables your team to efficiently plan, develop and collaborate on a cloud-based solution.

To save time and money, improve design, electronics and machining. With Fusion, you can use resources more efficiently and increase capacity more effectively. It is also possible to automate work processes and make them more efficient.

- CAD or simulation

- Fusion Extensions

- Basic functions

Ideally suited for

Precise planning and creation of digital models and technical drawings to support product development and manufacturing.

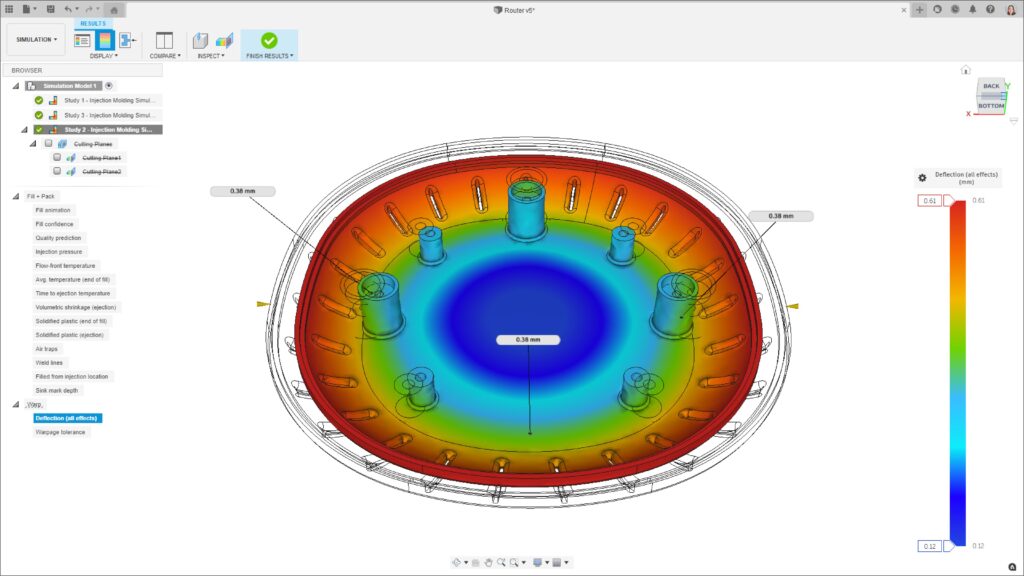

Use digital models to perform tests and evaluations to optimize the behavior and performance of a design under real-world conditions.

Extensions customized to your needs

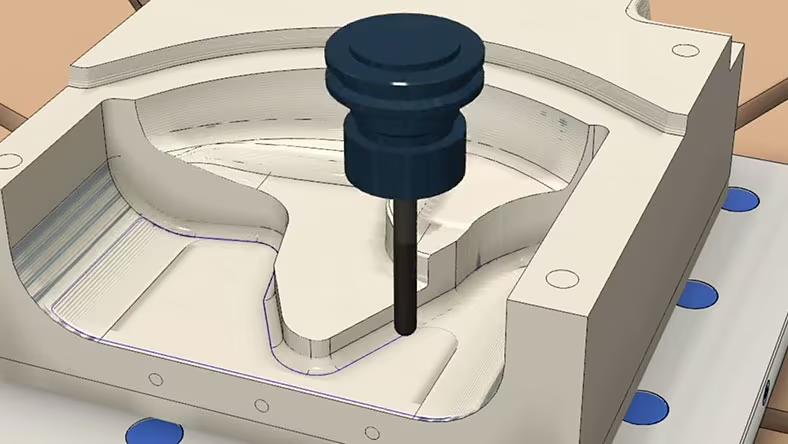

Manufacturing Extension

Offers you additional functions in 3- to 5-axis CNC machining. Especially for sheet metal-based nesting and manufacturing as well as metal-based additive manufacturing.

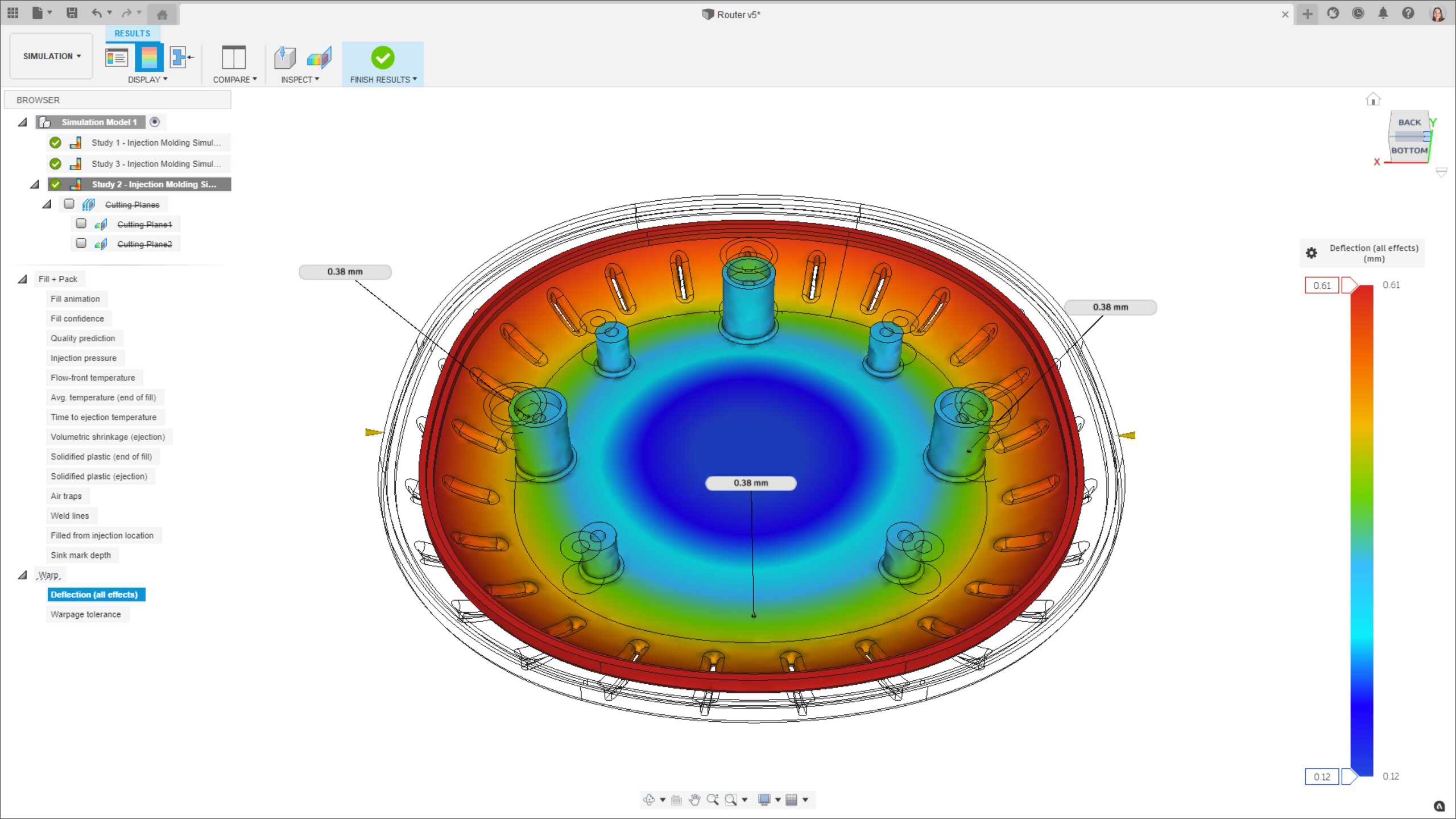

Simulation Extension

Unlimited number of calculations in the cloud for generative design, FEM, electronic cooling or even injection molding. Easily optimize your designs and the behavior of your components.

Design Extension

Automate complex geometries to improve the behavior and design of your products.

Signal Integrity Extension

Especially for the optimization of your PCB designs and analysis of electromagnetic behaviour. The impedance of each critical transmission line can also be controlled.

Manage Extension

Change requests, version management or even automatic order list numbering and parts list management can be adapted easily and efficiently.

Basic functions

Detailed visualizations of complex products with exploded views and animations.

Use integrated collaboration tools to bring teams together and manage product data.

Simple setup of SPICE (simulation program with integrated circuit highlighting)

Test and simulate designs to ensure they hold up under real-world conditions. Create digital simulations to reduce the cost of prototyping.

With generative design, you can explore various production-ready results that meet your design specifications.

Frequently asked questions (FAQs)

Why can I test and analyze simulations in Fusion?

To check structural integrity, thermal loads and vibration behavior of your designs. This includes static stress analysis, thermal analysis, modal and stability analysis to ensure the performance and safety of your components.

How can I use Fusion to improve design and manufacturing processes?

With Fusion, I’m experiencing the future of design and manufacturing through a cloud-based solution that helps my team plan, develop and collaborate efficiently. I can automate design, electronics and machining to save time and costs, as well as optimize resources and increase capacity with less effort. In addition, automated workflows allow me to make our processes more efficient.

What options does Fusion offer me for carrying out simulations and analyses?

With Fusion, I can use digital models to perform tests and evaluations to optimize the behavior and performance of my designs in real-world conditions. I can test my designs to ensure they stand up to real-world conditions and create digital simulations to reduce prototyping costs by using fully validated solvers.