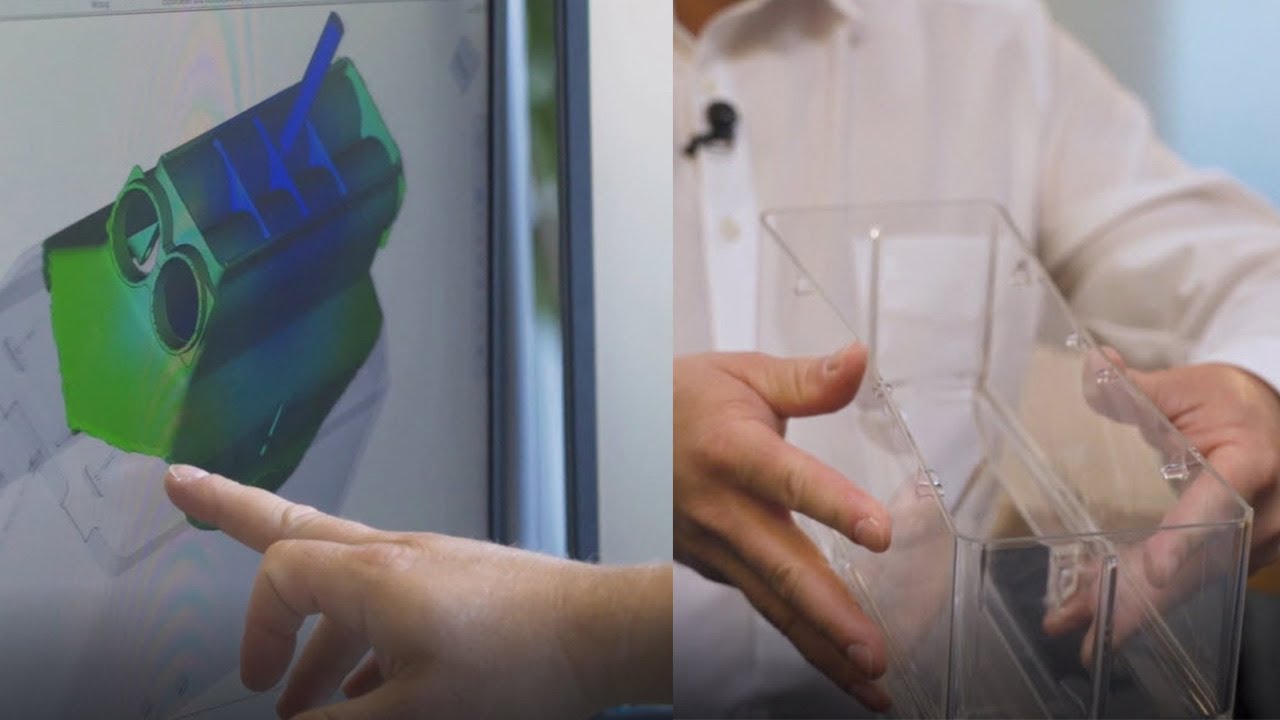

MOLDFLOW: Simulation for injection molding and injection compression molding of plastic parts

Manufacturing plastic parts even more efficiently thanks to sophisticated simulation software

The new version 2023 of Moldflow is here: Improved functions for even more efficient simulation

Moldflow® simulation software helps you solve problems in injection molding and injection compression molding of plastic parts. The advanced tools and simplified user interface help you with challenges such as part warpage, cooling channel efficiency and cycle time reduction.

The new version Moldflow 2023 – now even better:

We will be happy to present the new functions and improvements to you in person on October 21, 2022 at 10:00 a.m.

Here are a few examples in advance:

Injection molding simulation in Fusion 360

- Simulation of the filling process to identify surface problems depending on gate position, material selection and process parameters

- Based on the results, you can examine the filling, visual defects, as well as the distortion of the filling.

- Fusion 360 has an integrated advisor that provides suggestions for improvements where necessary

- Fusion 360 accesses a material database of more than 12,000 materials

Improvements to the surface

Solver optimizations

Scandium Tech Preview 2023 Update