- Comprehensive service portfolio

- High-quality, professional finish

- Customized solution

- Combination of 3D printing and conventional manufacturing processes

- Personal & competent advice

Post-processing and surface treatment

Our 3D printing services go far beyond the actual printing process. We pride ourselves on not only providing you with the best 3D printed parts, but also making sure they look and feel perfect.

This is precisely why we offer you not only 3D printing, but also comprehensive post-processing and surface treatment to make your parts a real highlight.

Our services in detail

Infiltrate

Sometimes it’s the little things that make the difference. By infiltrating 3D printed parts, we fill gaps and pores that occur during printing, making your components even more stable and resistant. In this way, we ensure a top surface that not only looks inspiringly good, but also functions properly.

Varnishing

Painting 3D-printed parts not only gives them an attractive appearance, but also protects them from external influences. An additional coating can improve UV resistance and scratch resistance.

Whether you want a plain tone or a bold color, we offer you the RAL colors that best suit your project. This not only gives your component a stunning look, but also the necessary protection

Mechanical processing of 3D printed parts

If precision is a challenge – we are exactly the right partner! Using processes such as milling, turning or grinding, we bring your components to the exact dimensions and achieve a smooth, high-quality surface – exactly according to your requirements.

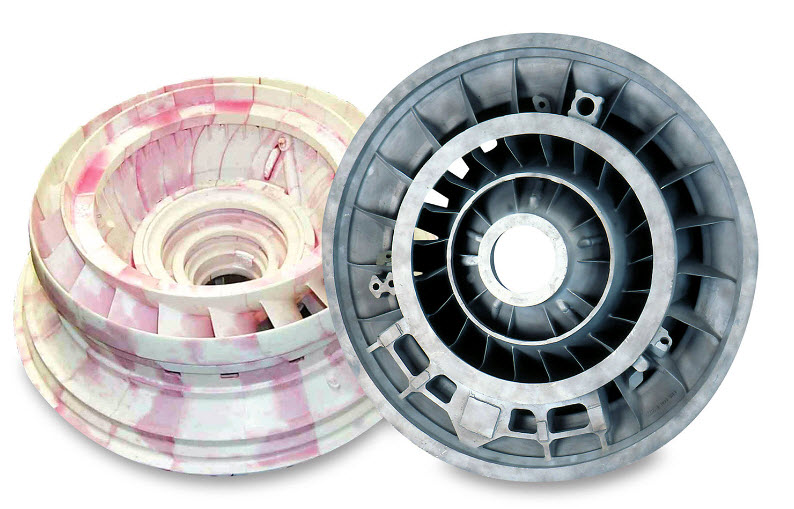

Pouring

3D printed parts can also be used for casting – we ensure that your 3D printed parts can be perfectly transferred into materials such as aluminum or stainless steel. The casting process ensures an excellent level of detail and mechanical stability that is up to any challenge!

Chemical smoothing

With chemical smoothing, we ensure a finish that looks and feels wonderful!

In this process, the top layer of the plastic part is liquefied under the influence of chemicals, resulting in a glossy surface. Depending on the duration and intensity of the treatment, the macroscopic surface structure can also be smoothed.

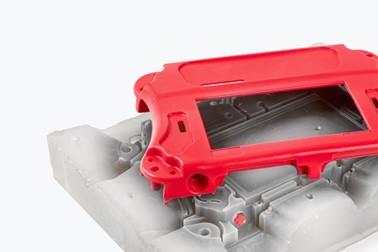

Vacuum casting

Are you looking for a fast and cost-effective way to produce high-quality small batches or prototypes? With our vacuum casting, we offer you the perfect solution for this.

Silicone molds can be used to produce exact copies of sample parts – with materials that come very close to the properties of injection-molded parts!

Polishing

We get the best out of your 3D print – with professional polishing, smoothing and finishing of your 3D printed components.

Whether it’s a functional prototype or a design object – a high-quality polish gives your component the finishing touches

Why our post-processing is crucial

Post-processing is the decisive step in getting the best out of your 3D-printed parts. Whether in mechanical engineering or product development – we will meet your requirements.

By using the latest technologies and years of experience, we ensure that every detail is processed perfectly. We know which way to go to get the best out of your 3D-printed parts.

Mechatronics & Robotics

Mechatronics & Robotics