- Tool-free production – no need to make molds

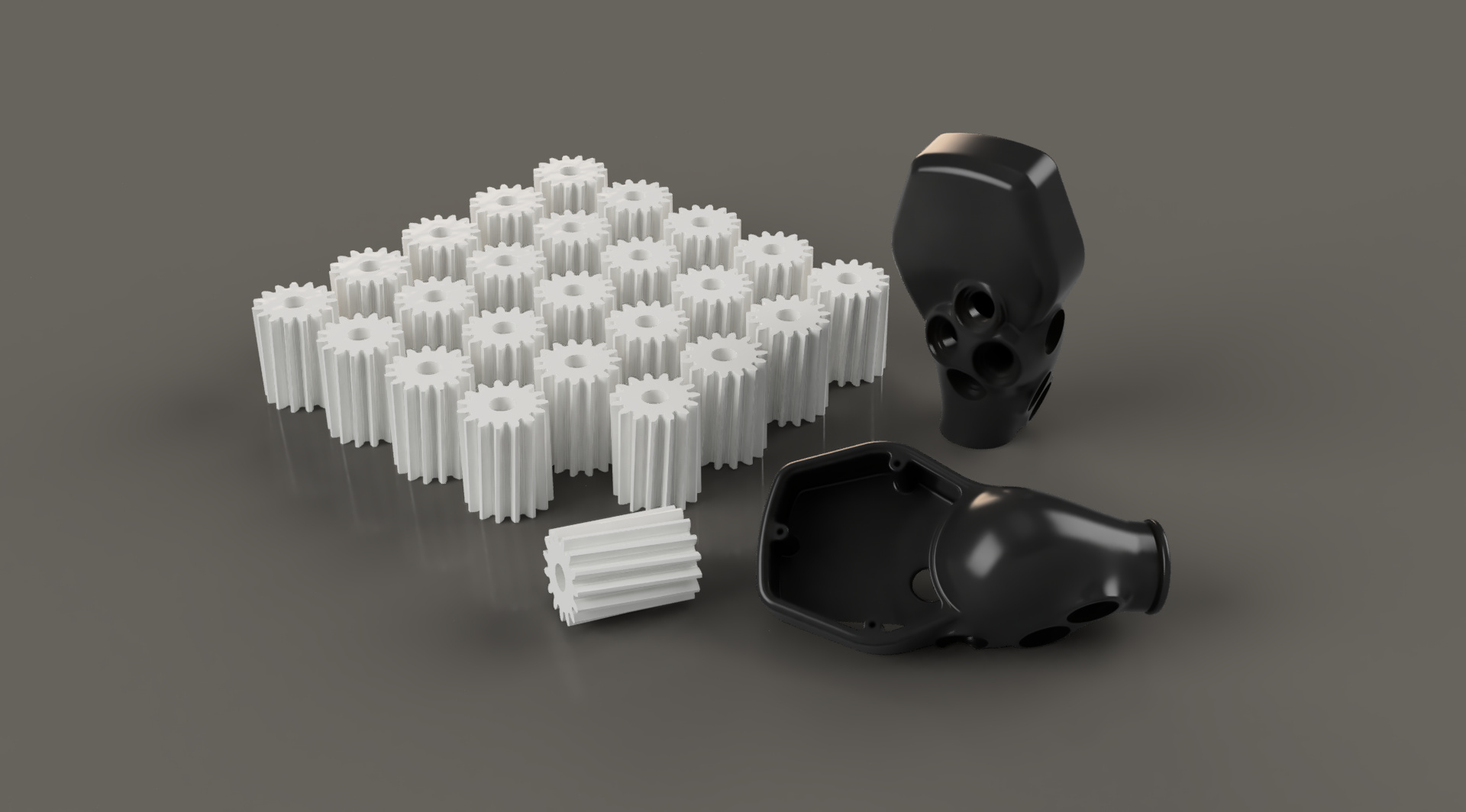

- Complex geometries also possible (high design freedom)

- Shorter time-to-market due to rapid production

- Simple & inexpensive product modifications possible

- Flexible selection of 3D printing materials & processes

- Extensive practical experience

- Numerous reference customers and success stories

Series production and small batches

At WESTCAM, we offer you customized solutions for series production from the 3D printer as a service. Take advantage of the benefits of additive manufacturing for series production!

Our state-of-the-art 3D printing service offers you a cost-effective, flexible and fast solution for the production of small and medium-sized series. Tool-free production in the 3D printer achieves decisive time and cost advantages and even extremely complex designs can be realized.

And best of all – the series parts can even be individualized on request and different components can be produced within a series. This advantage of mass customization is simply not feasible with conventional production. It is also comparatively easy to implement subsequent changes, as only the digital model needs to be modified.

Why 3D printing for series production?

- Cost savings – no expensive tools or molds are required

- High flexibility – changes can be implemented at any time

- Fast production – shorter development and delivery times

- Versatile materials – from plastic to metal for a wide range of requirements

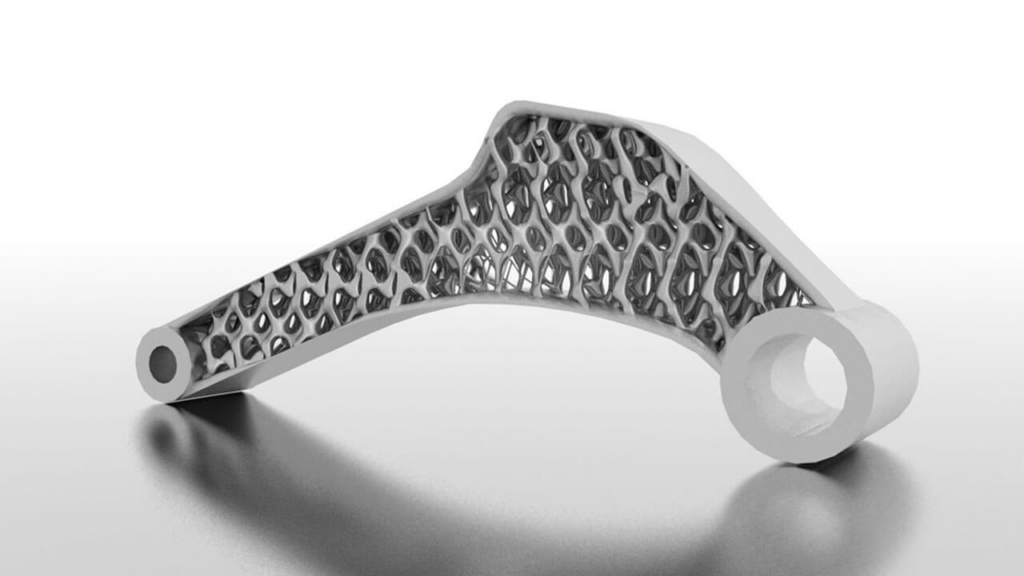

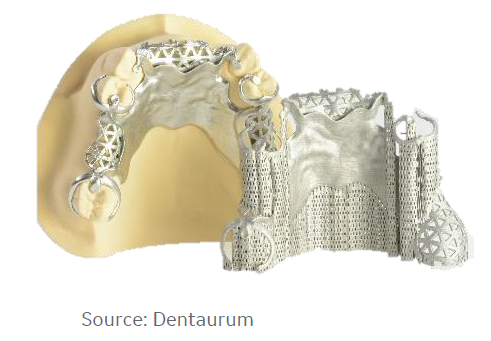

- Complex geometries – realization of structures that are not possible with conventional processes

Our service for your series production

- Consulting & optimization – We support you from the idea to the finished product

- Prototypes to large-scale production – customized solutions for your needs

- Material & technology selection – SLS, SLA, HSS, FDM & more

- Highest quality – precise production with tight tolerances and optimized post-processing

Before printing: CAD data & optimization

The better the input, the better the output. The quality of the CAD data plays a decisive role in the quality of the printed parts. Let us take a look at the CAD data . Thanks to our experience, we can usually provide valuable tips for optimizing the component – keyword: topology optimization.

“Quality first”

The delivery of high-quality components is our highest goal. All series parts can be optically measured and tested on request.

Frequently asked questions (FAQs)

Welche Informationen benötigt WESTCAM um ein Angebot zu erstellen?

In order to provide you with a precise quotation, we first need a 3D data set (e.g. STEP, STL, IGES). If you do not have a data set, you can contact us at any time. WESTCAM also offers construction and design services and the option of digitizing physical components using 3D scanning. If you already have a 3D data set, additional information such as number of pieces, desired material, color and intended use will help us. If this all seems a little overwhelming, we will of course be happy to advise you.

Ist die Qualität 3D-gedruckter Serienfertigung mit der Qualität herkömmlicher Serienfertigung vergleichbar?

See for yourself: You will see that components produced in series using additive manufacturing are indistinguishable from injection-molded series production. In fact, even more complex geometries and shapes are possible in series production with the 3D printer than with the conventional manufacturing method.

Ab welcher Stückzahl lohnt sich die Serienfertigung aus dem 3D-Drucker?

Series production from the 3D printer is already worthwhile from a quantity of 1!

Dental prostheses, for example, are individually adapted to the patient and are already being produced in series on 3D printing systems. In this area, 3D printing has long since replaced the conventional casting process.

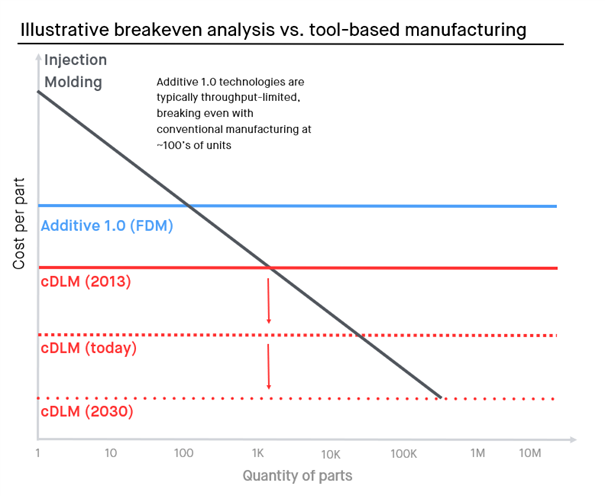

Wie wirtschaftlich ist 3D-Druck-Serienfertigung bei großen Mengen ab ca. 1.000 Stück

3D printing is also becoming increasingly economical for the production of large quantities of a component. In the cDLM process, several 1,000 pieces of small to medium-sized components can be produced on demand without tools in a very short time. Continuous Digital Light Manufacturing (cDLM) is a patented generative manufacturing process from WESTCAM partner ETEC.

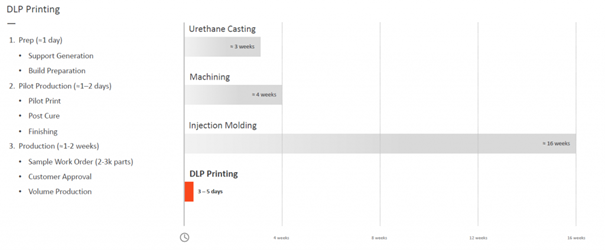

The DLP process is ideal for large components. Digital Light Processing (DLP) is a technology in which a projector projects an image onto a vessel filled with synthetic resin. As a rule, UV projectors are used, which then harden the synthetic resin in the areas that are exposed. The first prototypes can be produced with this technology in 1-2 days – a series of 1,000 to 2,000 pieces in a few weeks. Tool-free production enables rapid design changes in the series process without additional costs and production stops.

Mechatronics & Robotics

Mechatronics & Robotics