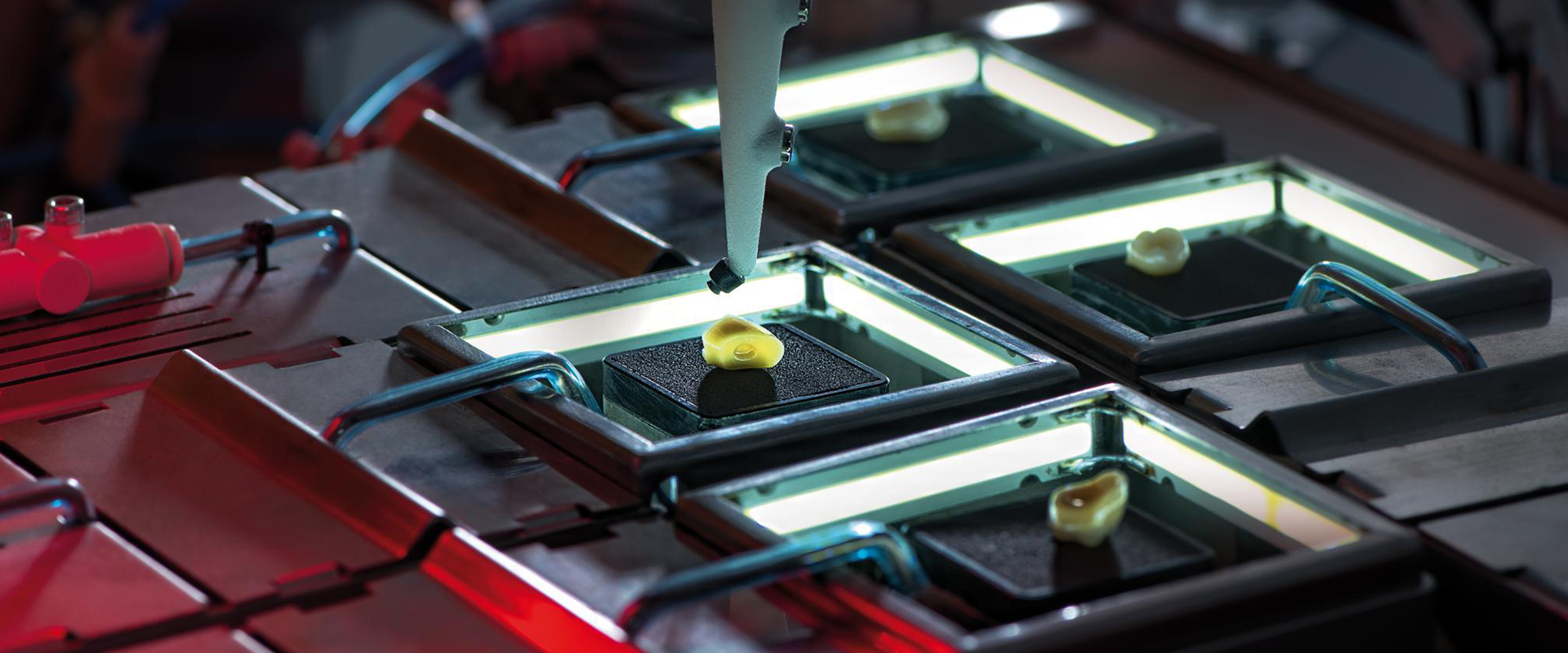

TMM – Tooth Mounting Machine

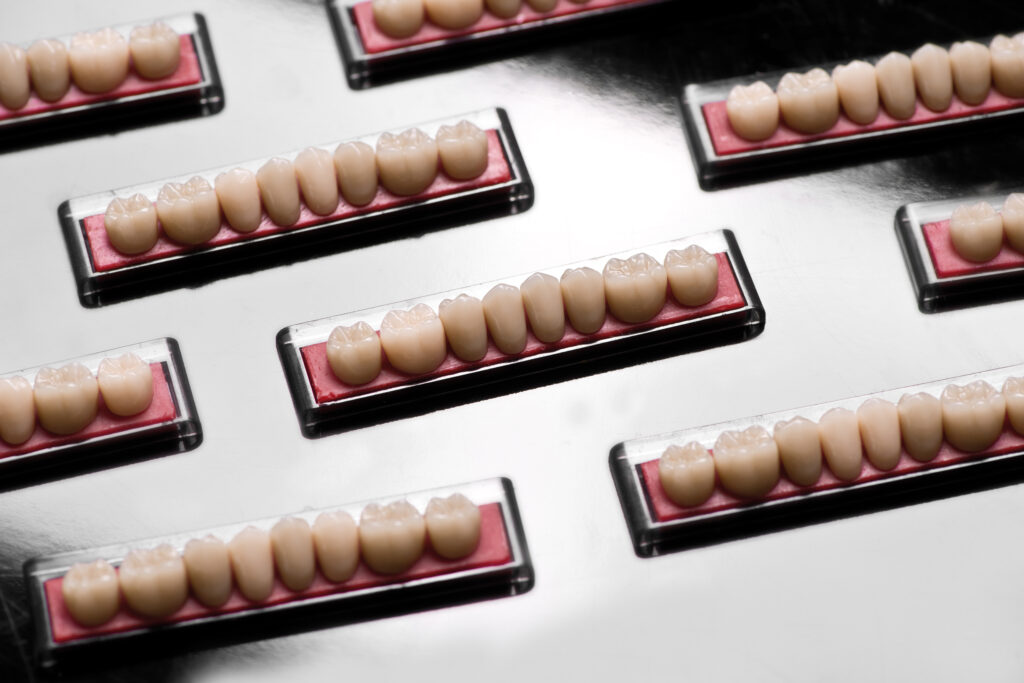

Fully automated gripping and placement of individual teeth on wax strips

Imaging processes are used to determine the current position of the teeth and precisely control the inserting machine. Loose teeth are placed precisely on empty wax strips. The finished wax strips are forwarded to the warehouse or dispatch.

- Up to 1,800 teeth per hour

- Fully automatic insertion of teeth on wax strips

- No position or directional orientation necessary

- Consistently high mating quality

- System can be expanded with labeling modules

- High autonomy for unstaffed night and weekend shifts

Used successfully by WESTCAM dental customers worldwide: Fully automated gripping and placement of individual teeth on wax strips. High speeds with maximum precision. Dental industry know-how for almost 20 years.

Consistently high mating quality

The TMM – Tooth Mounting Machine supplies production data in real time and can be integrated into the production planning system.

The constant speed achieves better results compared to manual stitching, while maintaining the same high quality.

Other advantages include low maintenance requirements and flexible use.

The TMM – Tooth Mounting Machine can be operated both as a stand-alone system and together with a sorting system and an additional storage unit.

Frequently asked questions (FAQs)

Do the teeth have to be arranged in a certain position in order to fit them efficiently on wax strips?

No, no positional or directional orientation is required for inserting the teeth! Our Gripplanning© software recognizes the position of the teeth and calculates the possible grip points in order to control the robot correctly.

How many teeth can be set per hour?

Up to 1,800 teeth per hour are possible with the TMM – Tooth Mounting Machine.

Is it possible to insert other parts with the TMM – Tooth Mounting Machine?

Yes, we also develop production systems for products and parts outside the dental industry.

Mechatronics & Robotics

Mechatronics & Robotics