M Line

Modular machine concept with innovative features

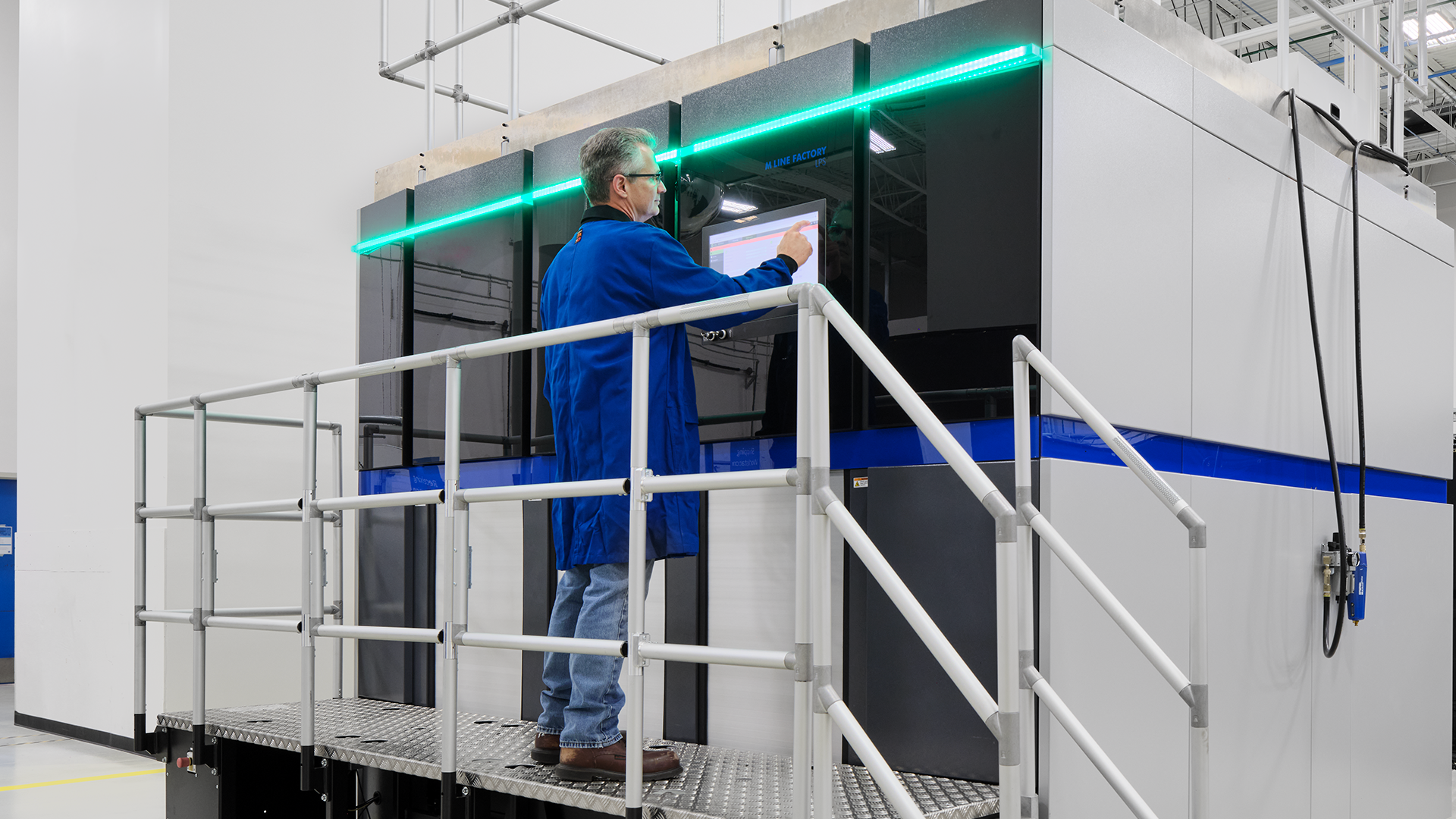

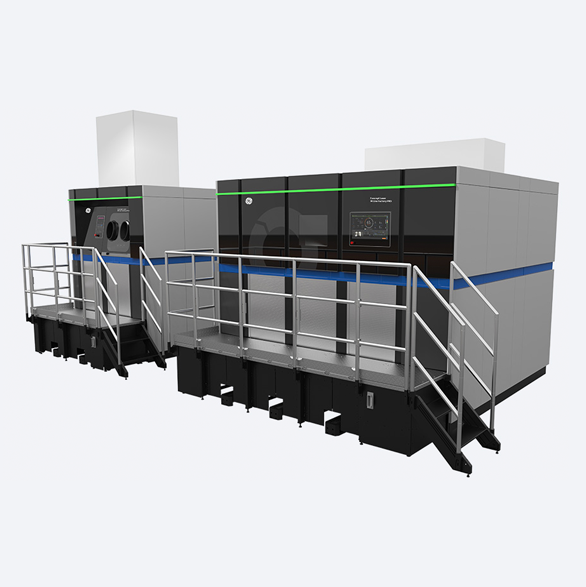

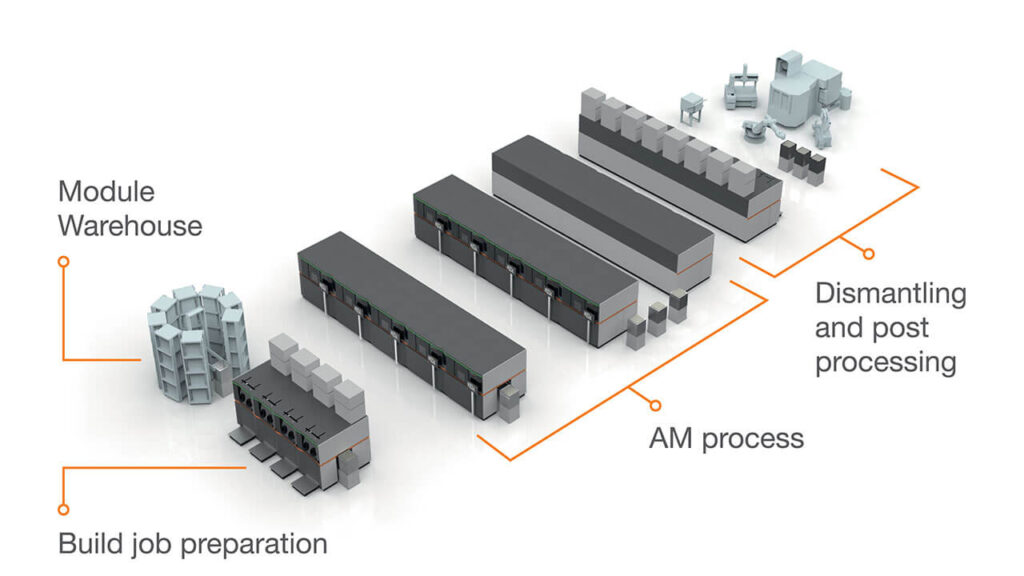

With its modular machine architecture and innovative features, the M Line, formerly known as the Concept Laser M LINE FACTORY, sets new standards for the cost-effective series production of additive metal components.

This advanced production solution is ideally designed for the needs of Industry 4.0, ensures maximum efficiency and sets new standards in additive manufacturing technology.

- Modular architecture

- More security

- Consistently high quality

Modular architecture

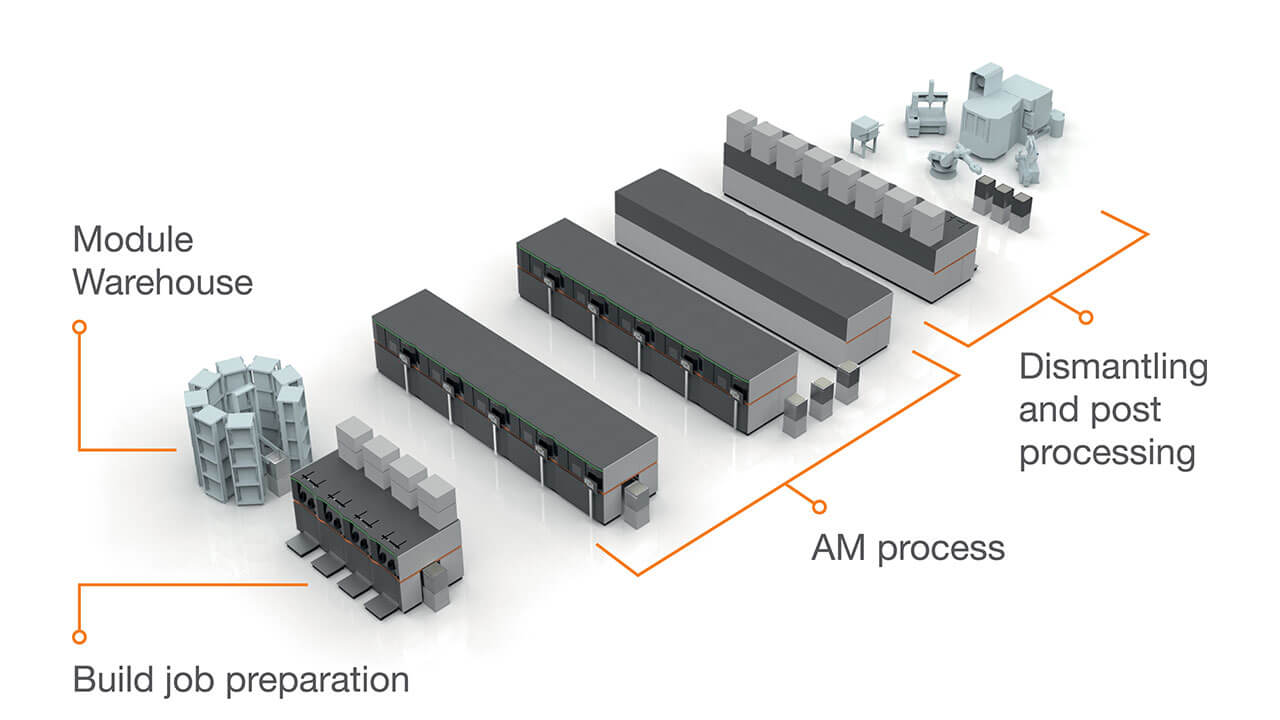

Thanks to the modular structure of the M Line, your production and set-up/disassembly processes can be spatially separated from each other. This reduces downtimes and increases the efficiency of your production.

To increase productivity, it is possible to integrate several machines into automated networks that communicate with each other

More security

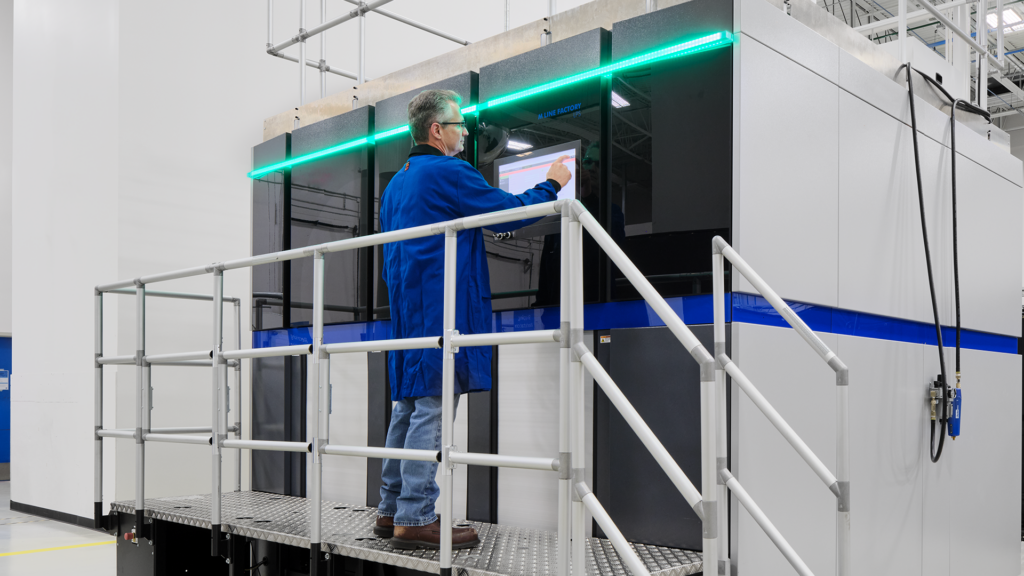

The M Line features advanced technology that includes a time-saving coating strategy, switchable filter units to maximize machine uptime and specially developed software for series production.

A special safety concept also ensures safe operation during the entire production phase.

Frequently asked questions (FAQs)

How does the modular architecture of the M Line support efficiency in the series production of additive metal components?

The modular architecture makes it possible to separate production and set-up/disassembly processes spatially. This minimizes downtimes and leads to considerable cost and time savings.

Which innovative technologies make the M Line the ideal choice for companies aiming for Industry 4.0 standards?

A time-saving coating strategy, switchable filter units, software for series production and the highest safety standards guarantee a stable production process from quantities of 1 to 10,000.

Mechatronics & Robotics

Mechatronics & Robotics