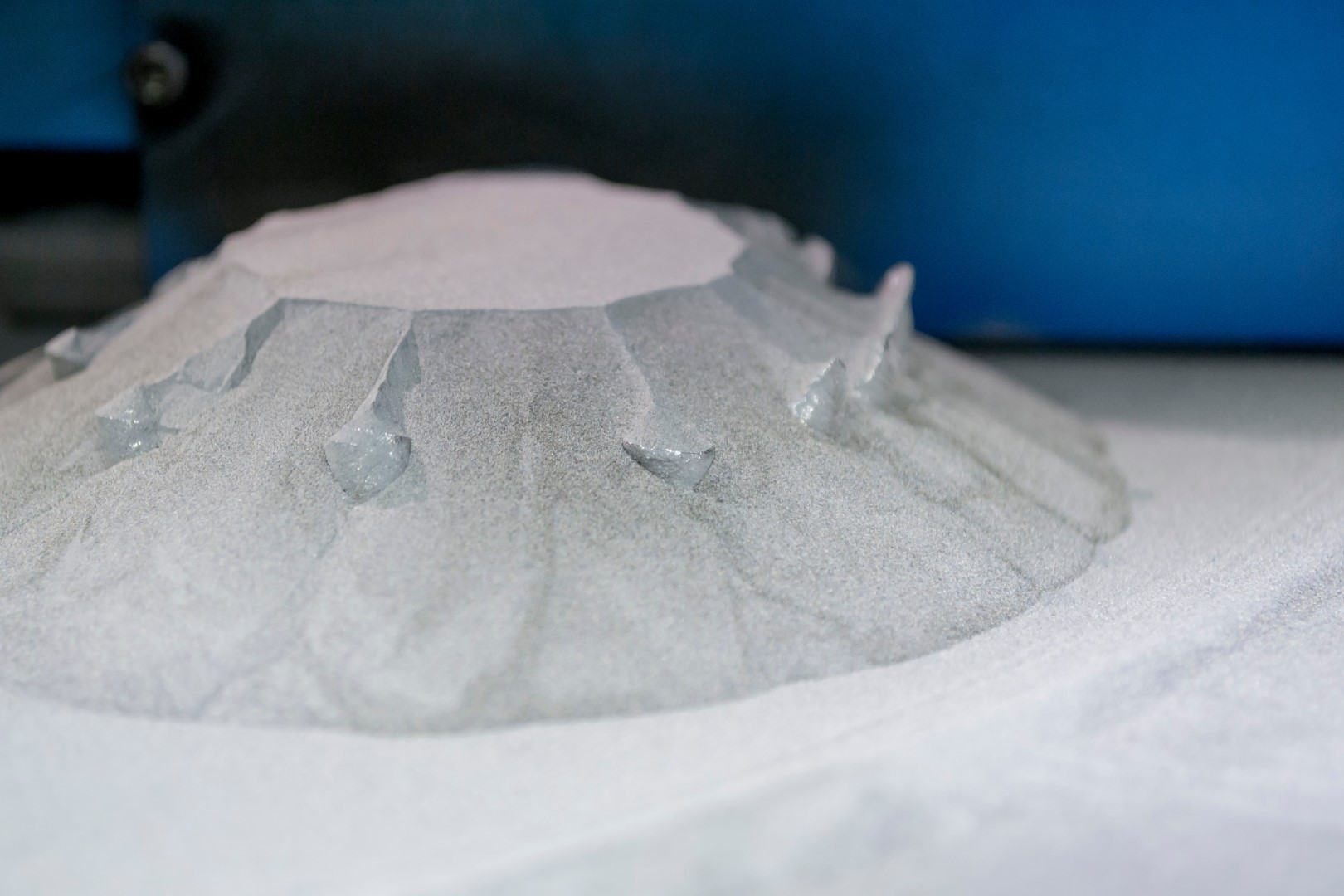

Metal powder

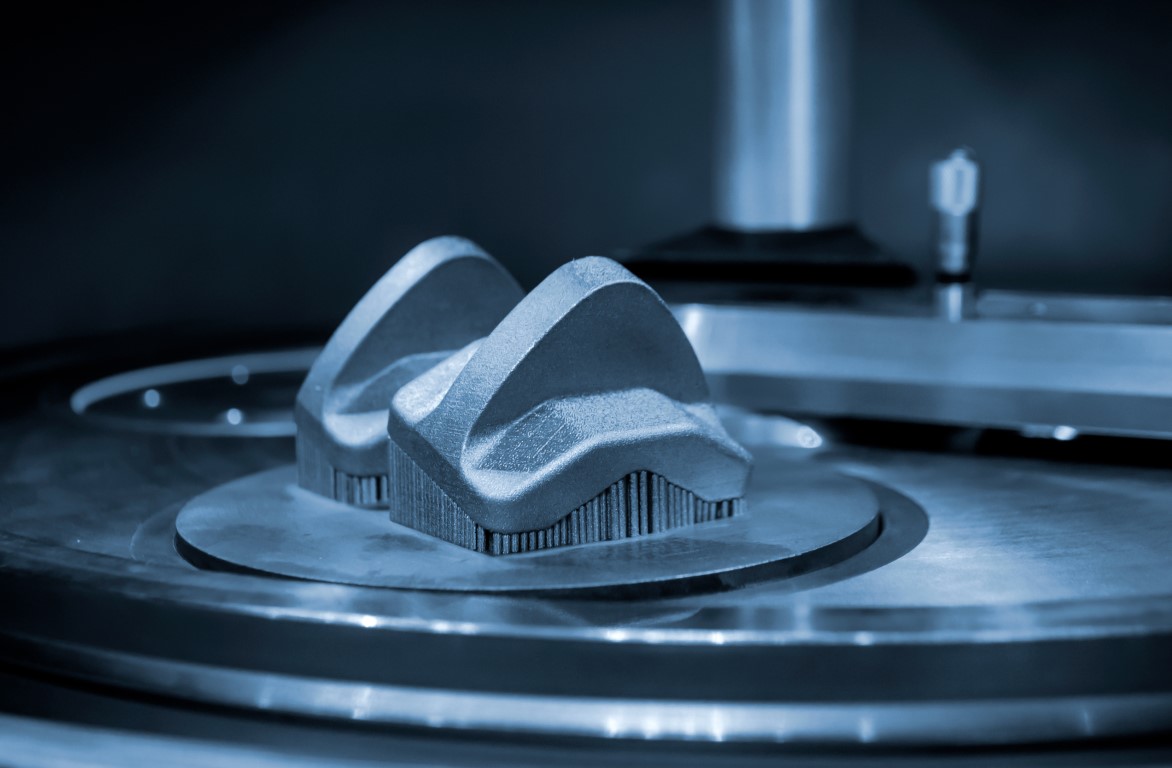

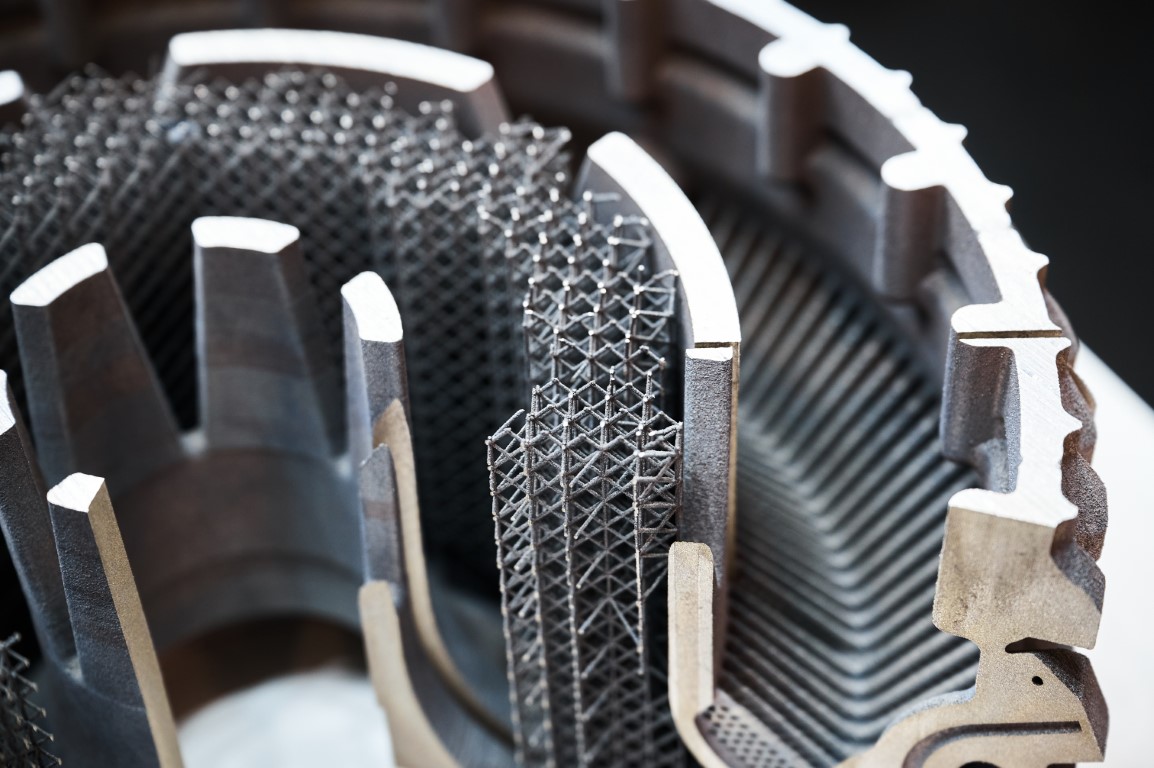

Optimized metal powders for maximum performance in additive manufacturing

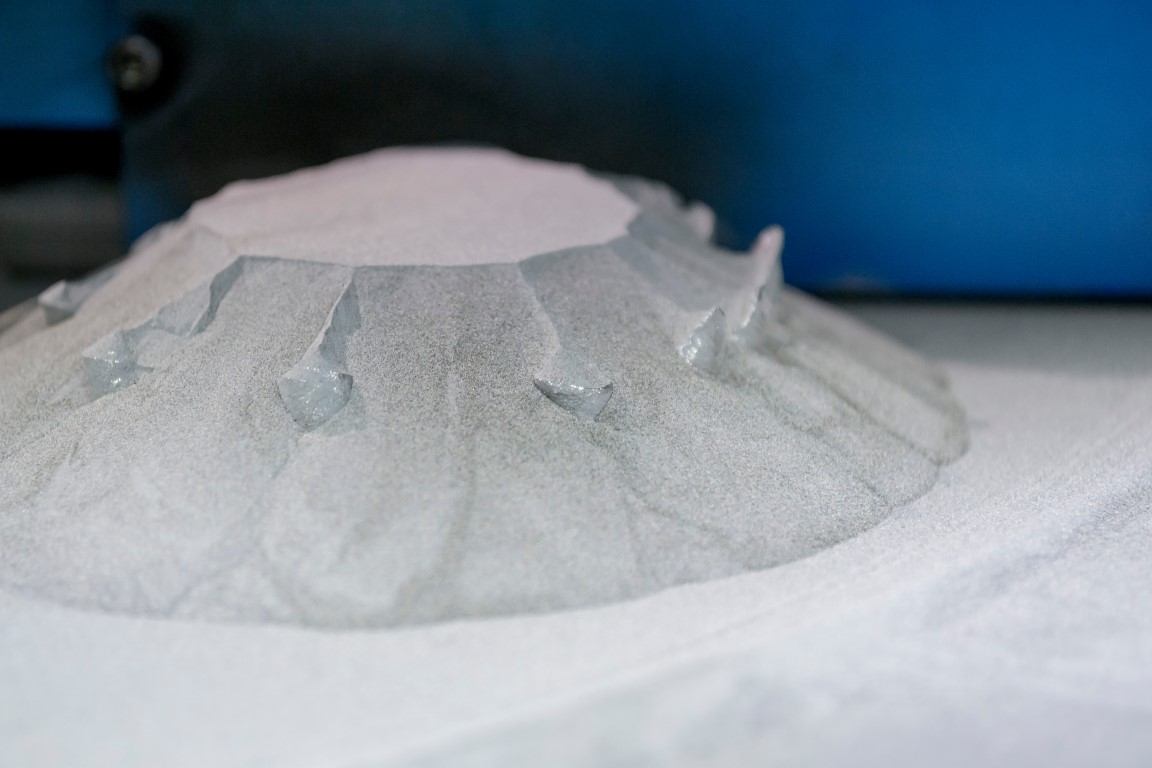

Discover Colibrium Additive’s comprehensive metal powder portfolio, designed for seamless integration into our additive manufacturing environment. The powders, produced by advanced plasma atomization, offer outstanding performance, quality and safety.

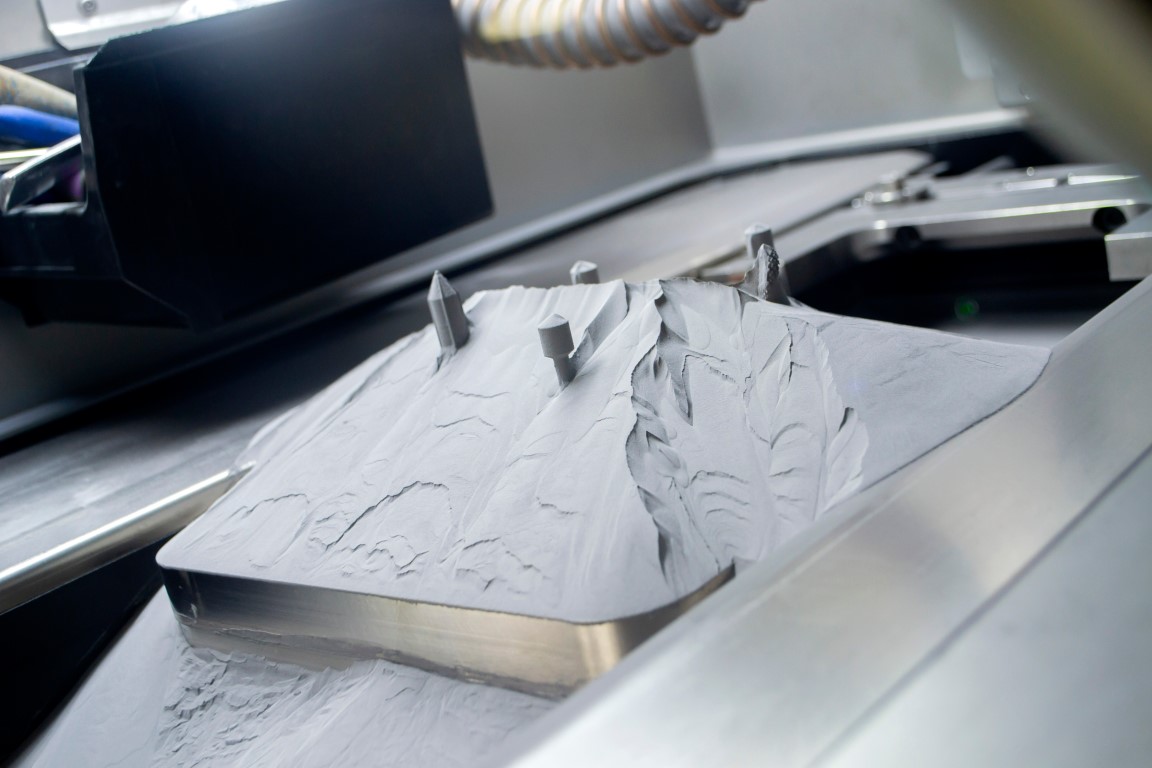

They improve the flowability, spreadability and surface quality of your parts and minimize porosity to ensure maximum material performance. Optimize your production with precisely matched metal powders for additive manufacturing.

Frequently asked questions (FAQs)

What are the advantages of Colibrium Additive’s metal powders?

The metal powders, produced by plasma atomization, offer improved flowability, spreadability and surface quality. They minimize porosity and maximize material performance, resulting in higher quality end products.

Which metals are available in powder form?

In addition to frequently used metals such as aluminum, titanium and a wide variety of steels and stainless steels, Inconel and copper are also possible. The list of materials that can be processed is constantly growing. Please feel free to ask one of our experts.

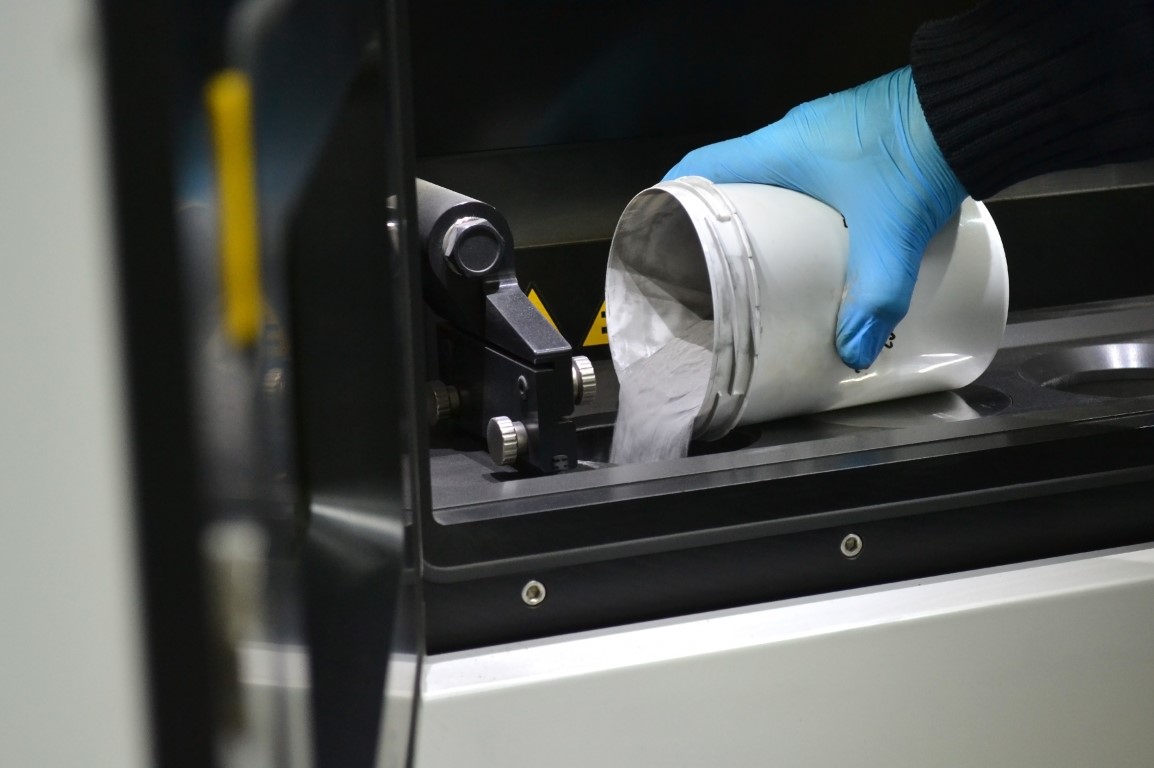

What safety aspects should be considered?

Powders can be divided into reactive (react especially with oxygen) and non-reactive materials.

The reactive materials require a higher safety standard as they must not come into contact with air.

Mechatronics & Robotics

Mechatronics & Robotics