Thanks to state-of-the-art technology, halcö Alfred Hörtnagl creates impressive prototypes of complete design families for fittings. The company is a traditional Tyrolean business that has stood for high-quality fittings and precise craftsmanship for generations. With state-of-the-art technology and a keen sense of design,

The challenge

From clay model to digital design model in the shortest possible time

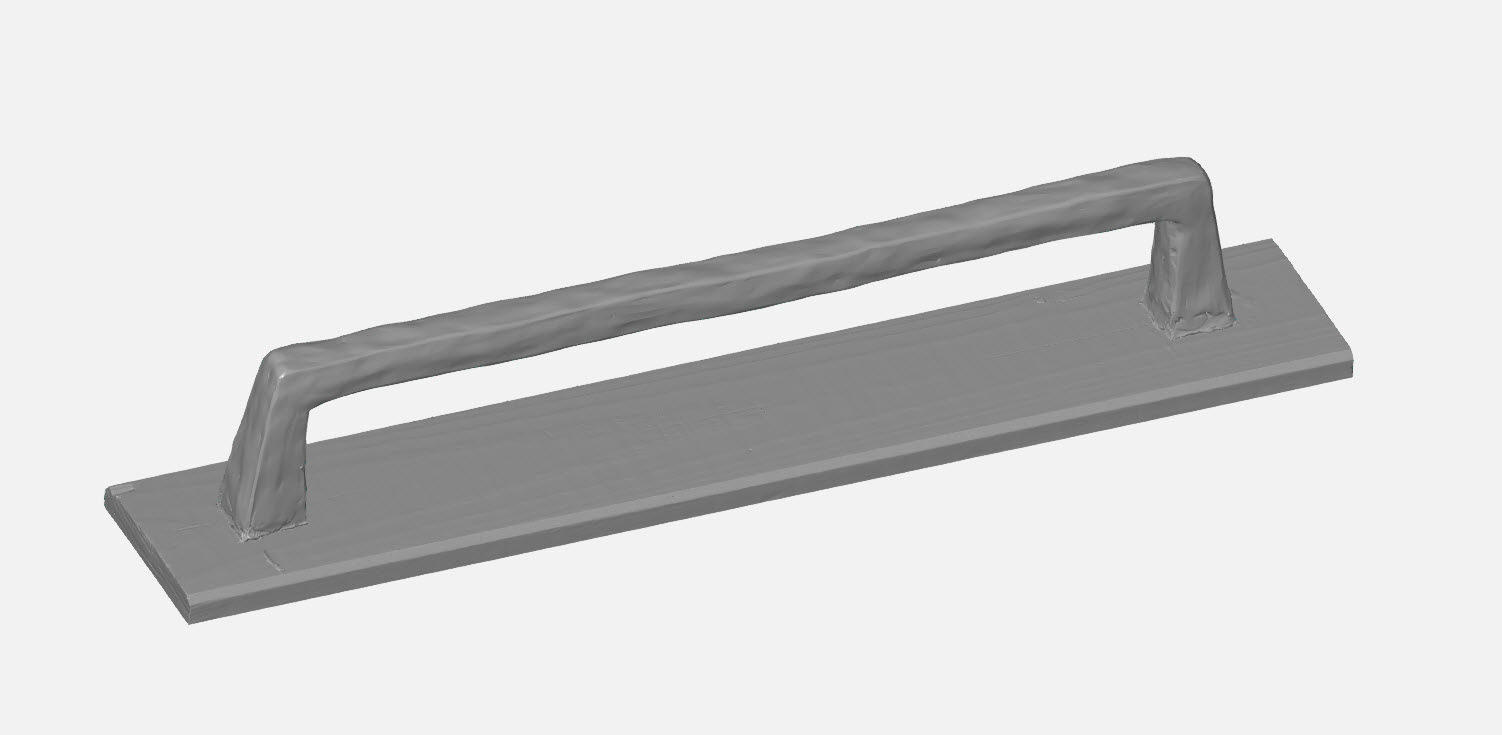

It all started with a hand-molded clay model, the shape of which had already been perfected. For halcö Alfred Hörtnagl GmbH, a traditional company with many years of experience in high-quality fittings, it was crucial to transfer this design efficiently into the digital world.

WESTCAM tackled the project together with halcö Alfred Hörtnagl GmbH under the motto “tradition meets high-tech”. State-of-the-art 3D scanning technology was used to create a detailed digital template. Based on this, designs for different fittings were developed and elaborated into a complete product family.

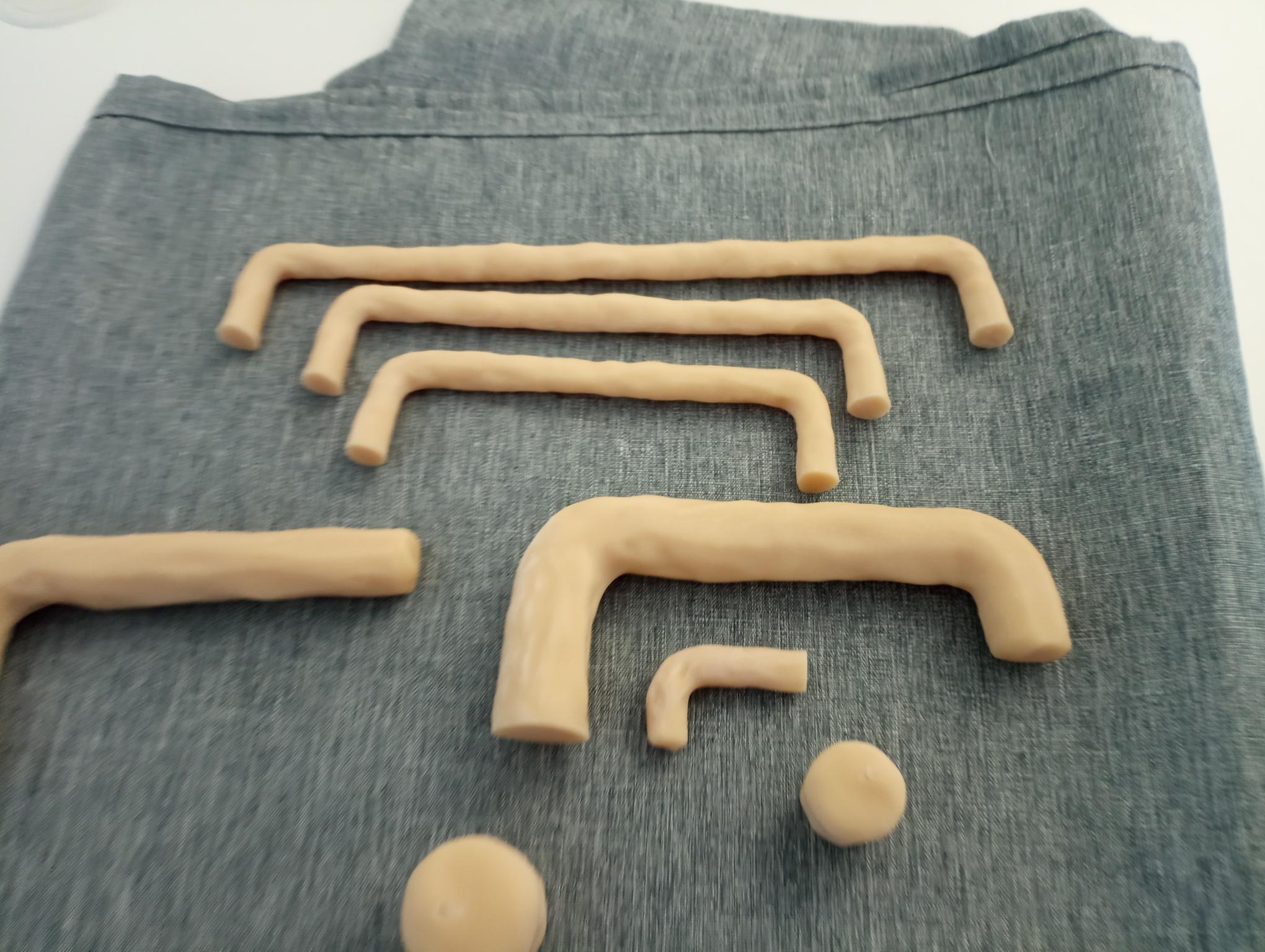

Fast prototypes through 3D printing

The decisive advantage became apparent in the next step: all of the designed models could be realized 1:1 using 3D printing. Thanks to

Advantages at a glance

Speed: As soon as the first draft is ready, the first prototypes can be produced within just a few hours

Cost efficiency: Low prototype costs also make several iterations economical

Tangible decisions: Full-size models convey a realistic sense of form, ergonomics and aesthetics

“Working with WESTCAM enabled us to quickly implement our models digitally and test prototypes directly. This allowed us to make design decisions quickly and prepare for production efficiently.”

The solution

3D scan & 3D print from WESTCAM:

This project is an impressive demonstration of how close cooperation between halcö Alfred Hörtnagl GmbH and WESTCAM accelerate the creative process and at the same time open up new possibilities for design and product development. The combination of traditional model making at halcö Alfred Hörtnagl GmbH and modern digitalization and fast 3D prototypes from WESTCAM paves the way for innovative, high-quality solutions – efficient, precise and tangible.

WESTCAM as your extended workbench

Our 3D printing service is ideal for pilot projects or individual productions. You can test your options flexibly and without risk:

Want to find out more about your options with 3D printing & 3D scanning?

Contact us now

Mechatronics & Robotics

Mechatronics & Robotics