In production, it’s not just what happens at the machine that counts – but also how quickly, clearly and thoughtfully the work gets there.

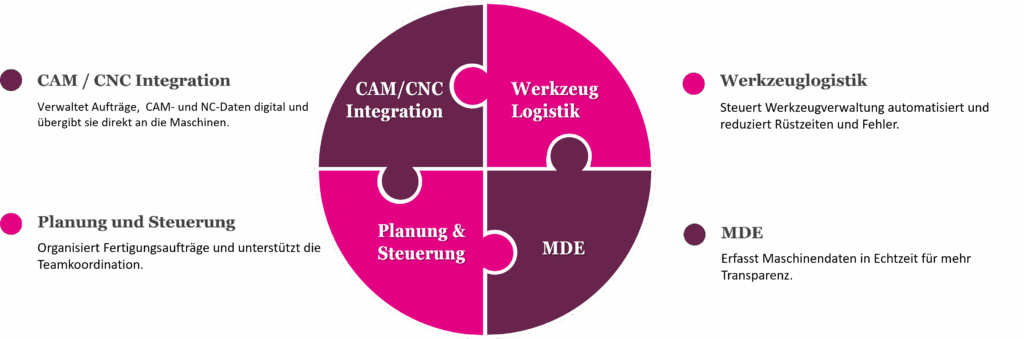

Many companies are already using hyperMILL, a very powerful solution for their CAM programming. But how do you turn well-programmed data into a smooth, productive manufacturing process? This is exactly where Hummingbird comes in: the agile Manufacturing Execution System (MES) that perfectly complements hyperMILL and digitally networks the entire production process – from planning to the machine to tool logistics. Our MES system has a modular structure, can be implemented quickly and grows flexibly in line with your current requirements. Hummingbird provides immediate transparency for work preparation and creates a fully integrated data flow. If you want to move away from Excel, paper routing slips and isolated processes, this is the right next step towards networked and transparent production.

How the combination of hyperMILL and Hummingbird works in practice, we recently showed together with Hans Georg Zwicker, founder and managing director of Hummingbird Systems, in two webinars recorded for you.

Module 1: CAM/CNC integration – a workflow that never stops

In many manufacturing companies, the CAM workstation remains a “digital island” – where high-quality programming takes place, but everything around it still requires a great deal of manual effort. With Hummingbird , this becomes a networked workflow that intelligently connects the planning of production orders, data provision and even machine control based on the production orders. Production projects are managed directly from hyperMILL and transferred digitally to the machine together with NC data, setup sheets and tool information.

The team can see where each job stands at all times and changes are immediately visible to everyone – without any manual updates. This provides work preparation, production management and even the machine operator with a shared, clear picture of individual orders and the entire production process.

Find out how this works in practice in our webinar on CAM/CNC integration with Hans Georg Zwicker:

Module 2: Tool logistics – everything where it’s needed

Tool logistics is often the stumbling block in an otherwise well-organized manufacturing process that is directly connected to hyperMILL .

Many companies have similar problems with tools and tool management – information is missing (e.g. previous usage time), set-up processes take too long or tools simply cannot be found. Hummingbird provides a systematic solution to this issue – and, as a central control element, takes over the complete handling: from storage and measurement to provision at the right time on the right machine.

Hummingbird is connected directly to the hyperMILL database, so there is no need to set up a separate tool database. This means that all data is available centrally right from the start.

Tools are uniquely identified by data matrix code or RFID, storage locations are digitally documented and all information flows automatically to where it is needed. This considerably reduces the workload – and with it the sources of error and costs for the tools.

There is also a separate webinar with Hans Georg Zwicker on this topic:

What’s next?

In addition to the two webinars already linked, we will also be holding webinars on the two other components of our modular MES system. Stay tuned to find out how you can drive digitalization and transparency in your manufacturing and production even further!

Curious?

If you find the webinars interesting and would like to discuss further ideas or specific requirements in your company, please get in touch with your contact person directly. We look forward to the exchange, your requirements and your ideas on the topic of Connected Manufacturing or MES at your company!

Mechatronics & Robotics

Mechatronics & Robotics