How state-of-the-art 3D scanning technology reveals new secrets from the da Vinci globe.

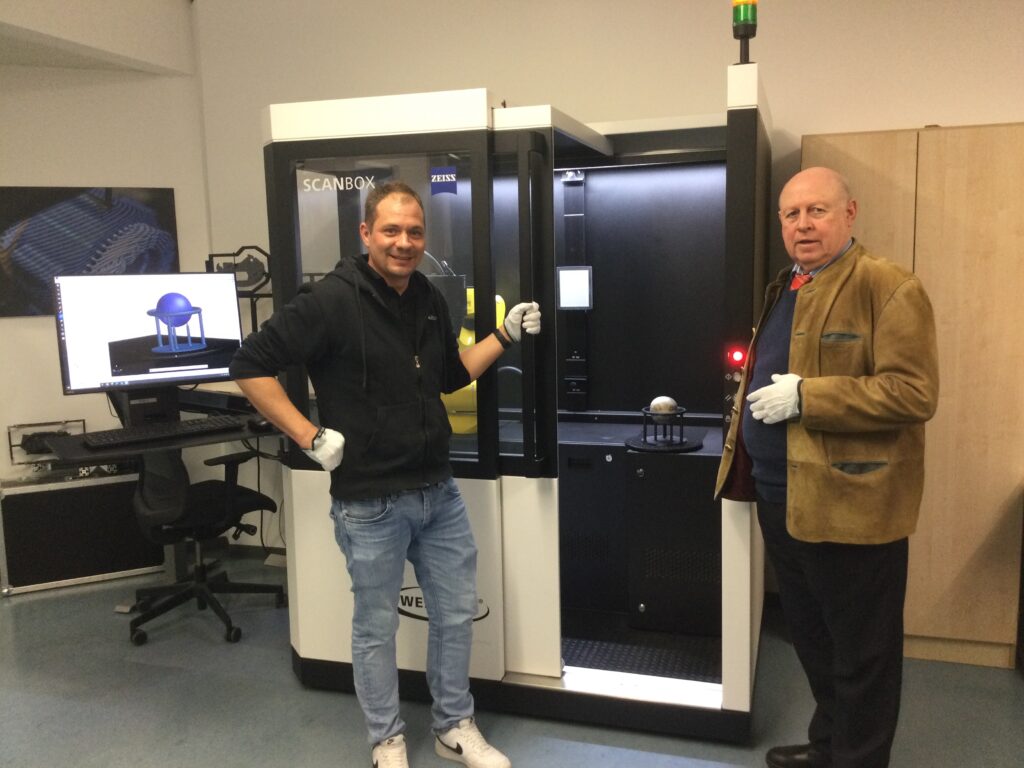

A palm-sized object, over 500 years old, made from two ostrich eggshells – and yet at the center of the latest high-tech research: the da Vinci globe from 1504 has been digitized for the first time worldwide using high-precision 3D scanning technology. This was made possible by our industrial 3D Metrology (ZEISS ScanBox). An exciting project that has also attracted media attention.

The challenge

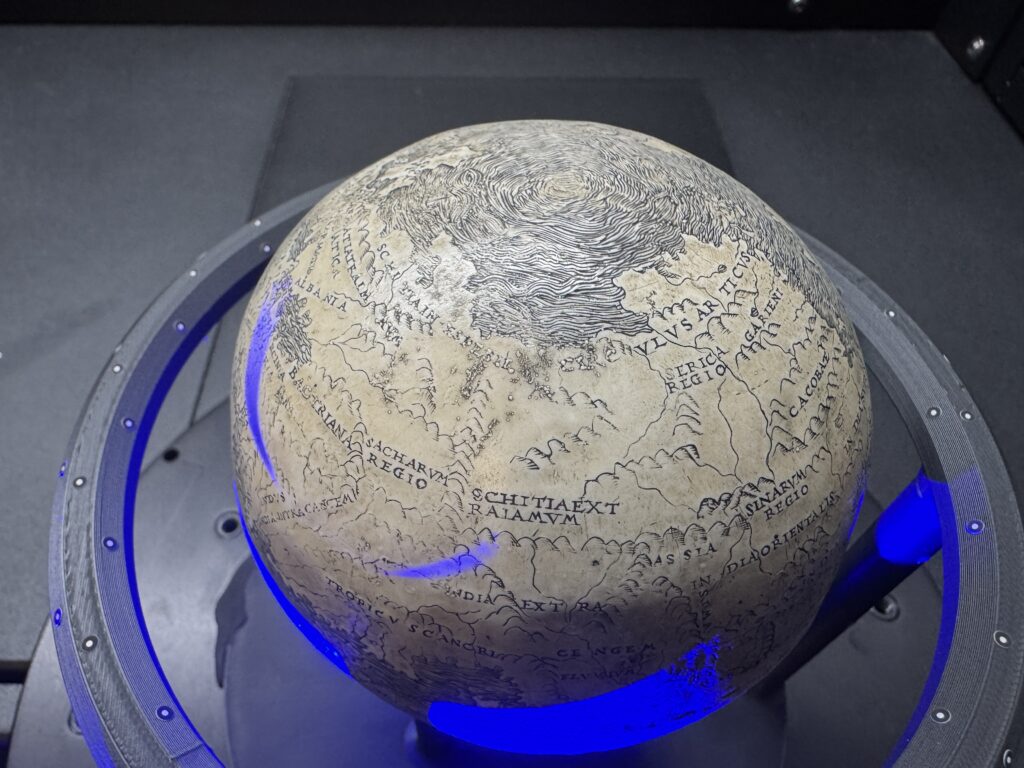

How do you research an object that is unique, extremely fragile and of inestimable historical value? The da Vinci globe from 1504 has a diameter of 11,2 cm tall and measures 1:80.000.000 and was made from two ostrich eggshells. Every touch involves risks, classical photography reaches its physical limits and many details remain hidden from the naked eye.

The central challenge was therefore:

How can the finest engravings, surface structures and manufacturing features be made visible without endangering the cultural object?

The da Vinci globe from 1504

The da Vinci globe is the oldest globe in the world where the New World (Mundus Novus) is shown for the first time. Its extraordinary choice of materials, precise cartography and artistic engravings have fascinated historians and globe researchers for decades.

But many questions remained unanswered: How precise are the continent lines? What traces of manufacture can be detected? And how were two fragile ostrich eggshells joined together so precisely over 500 years ago?

Why traditional methods are not enough

Photographs can depict shapes – but not haptics. They show surfaces, but no depth information. This two-dimensional view is not sufficient, especially for an object with micrometer-sized engravings.

“A photo cannot depict the haptic structure of an object – a 3D scan can.”

A non-contact, non-destructive and extremely precise approach was therefore needed to answer the unanswered questions.

Industrial 3D Metrology for a unique historical piece

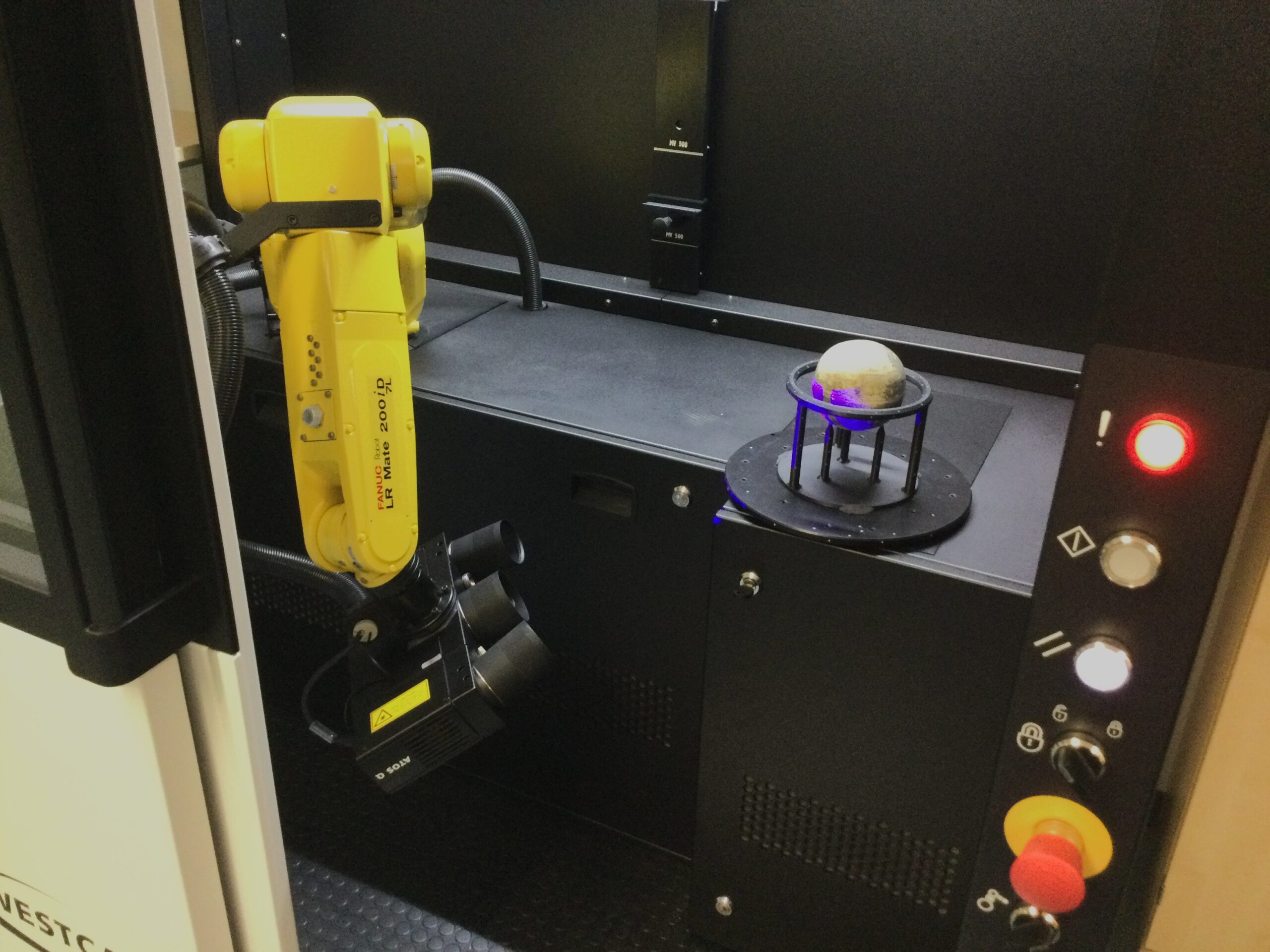

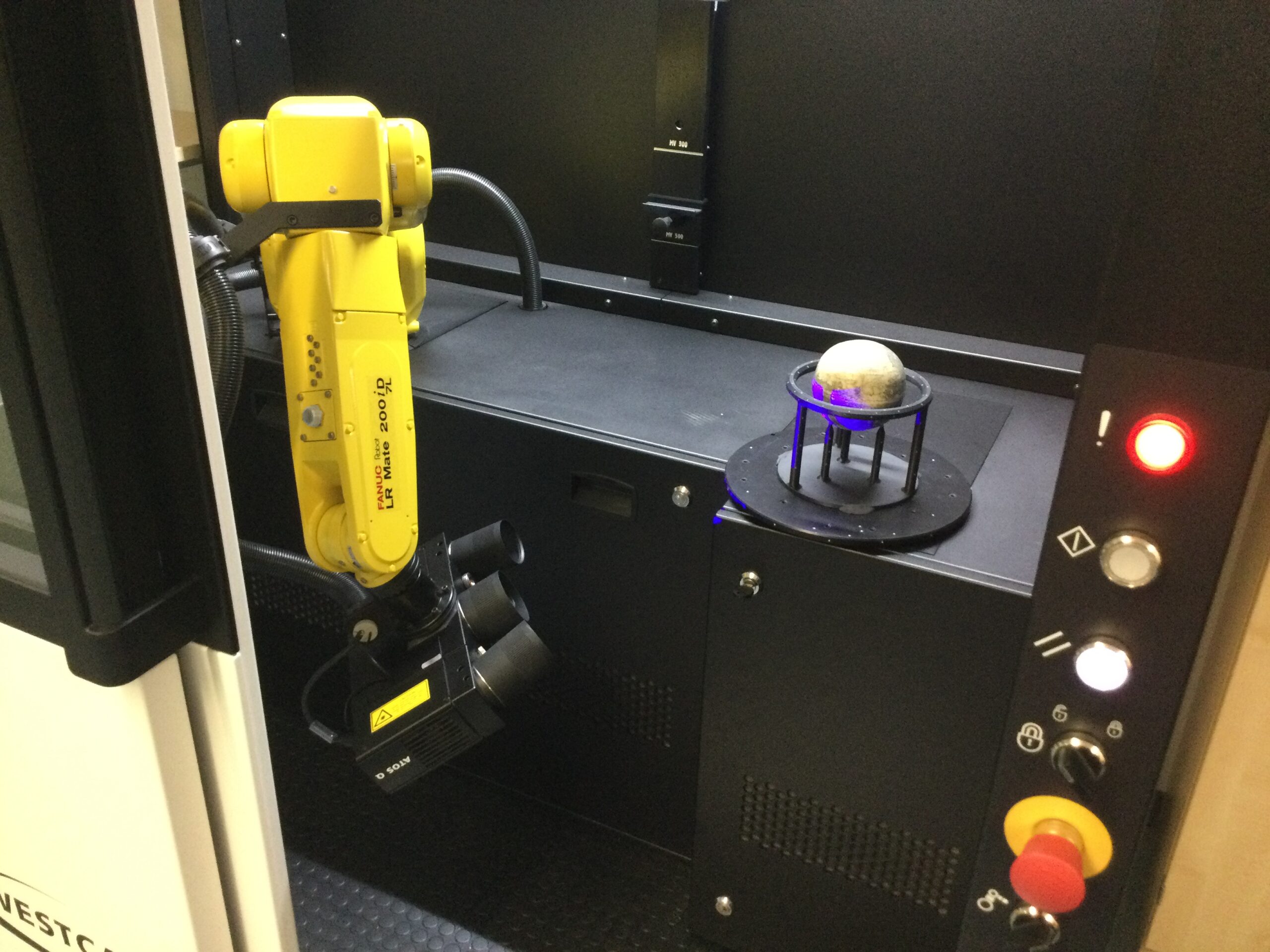

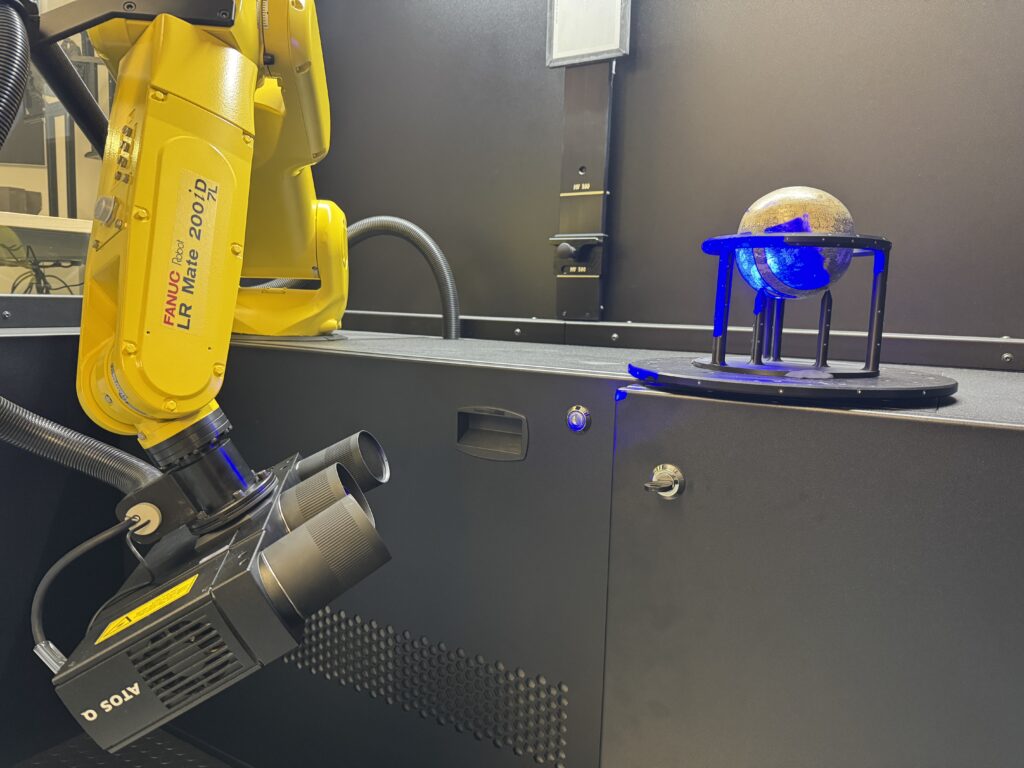

WESTCAM used state-of-the-art optical 3D Metrology for this extraordinary task – technology that is usually used in industrial quality inspection:

- ZEISS ScanBox 4105

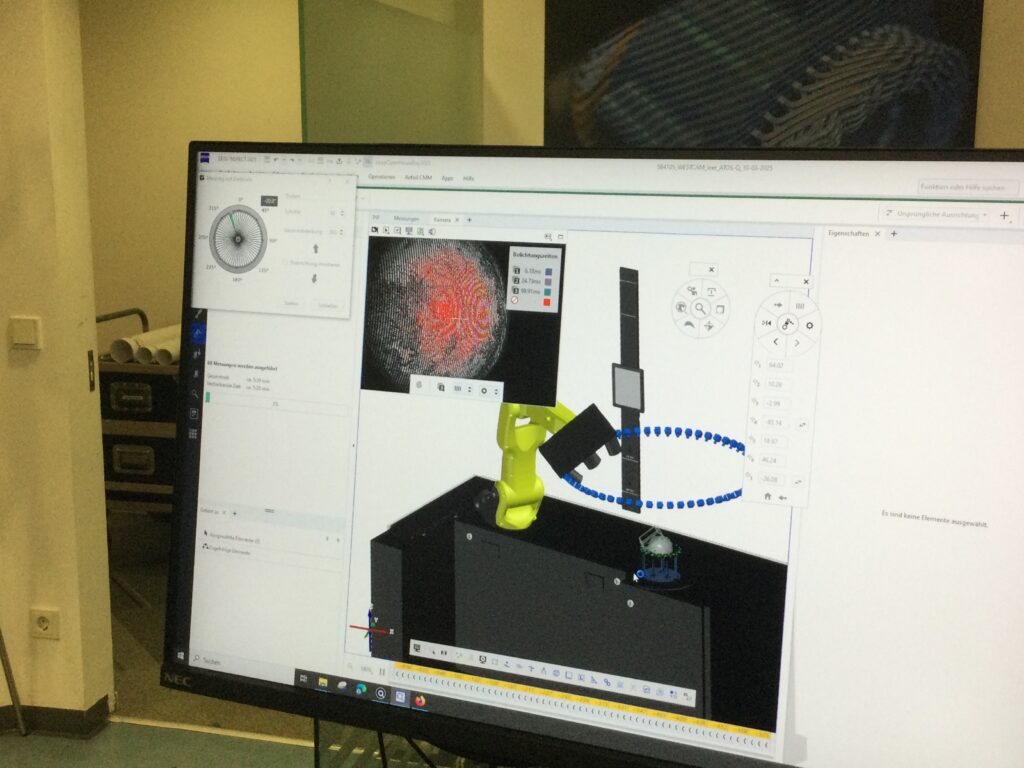

- ATOS Q high-performance 3D scanner with 2×12 megapixel cameras

- Scan resolution: 0,029 mm

- Measuring accuracy: up to 0,003 mm

This combination makes it possible to capture the finest surface structures in the micrometer range – exactly the level of detail required for scientific analysis.

For the scan, the globe was fixed on a specially developed, 3D-printed holding device. An automated robot in combination with a turntable module ensured that the sensitive surface could be captured completely and evenly – without mechanical stress.

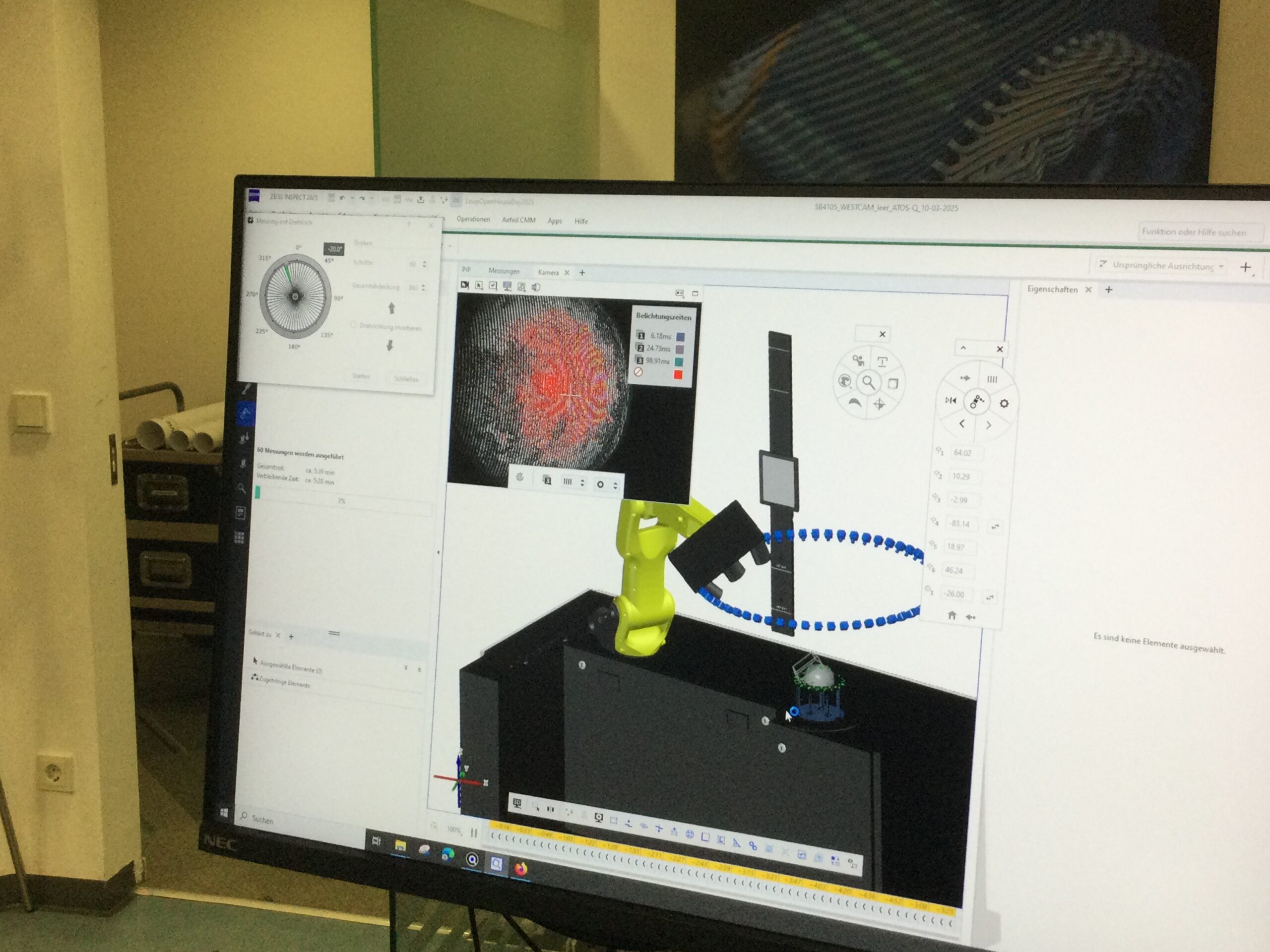

A photogrammetric measuring method with triangulation and bundle block adjustment was used, which enabled a complete and highly precise recording of the complex geometry.

New insights through digital precision

The resulting 3D data revealed details that were previously hidden:

- The position of the joint between the two ostrich egg shells.

- Extremely fine engraving structures in the range of a few micrometers

- Raised contours of contour lines, including South America

- Subtle traces of production that allow conclusions to be drawn about historical manufacturing processes

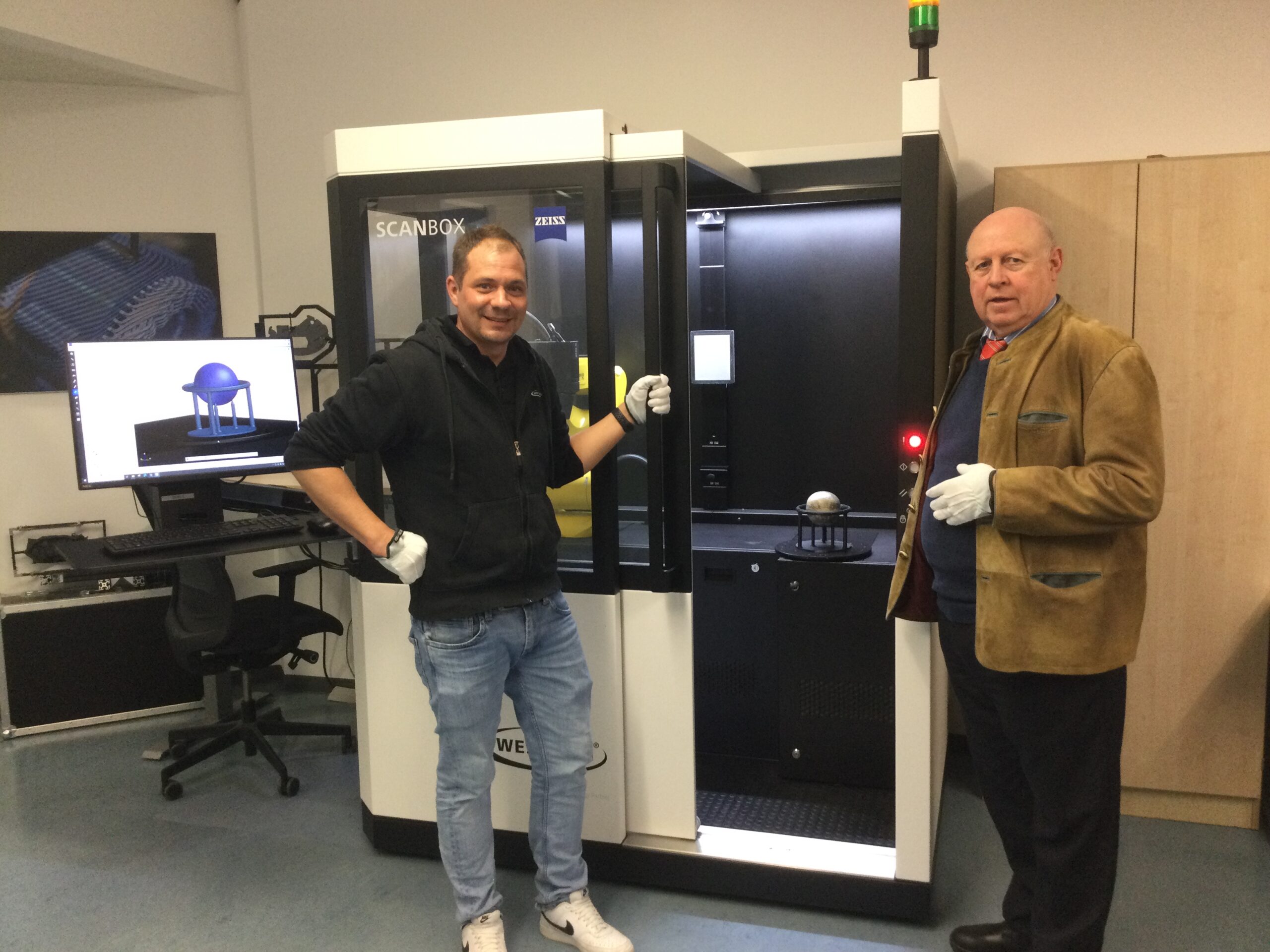

The survey was supervised by Prof. Dr. Stefaan Missinne, internationally renowned globe researcher and Fellow of the Royal Geographical Society.

This 3D scan brings to light scientific findings that were previously hidden.

The solution

When high-tech preserves cultural heritage

The world’s first high-precision 3D measurement of the da Vinci globe shows how modern industrial technology can solve key challenges in cultural heritage research.

What began as a seemingly unsolvable problem – making an extremely fragile object visible without touching it – finds its solution in the combination of high-tech, precision and scientific curiosity.

A project that provides impressive proof: The future of research often lies in the precise digitization of our past.

Click here for the ORF Tiol report

Mechatronics & Robotics

Mechatronics & Robotics