Competence: CAM Automatization

-

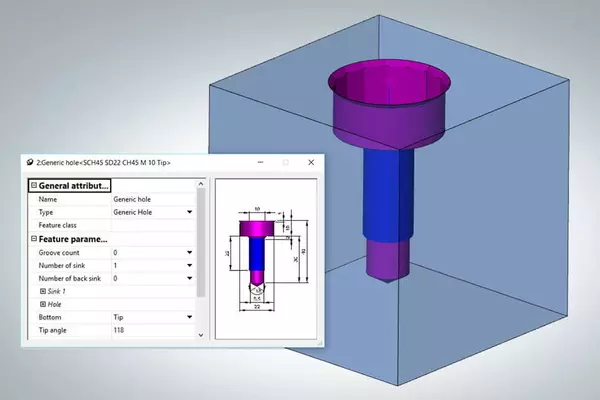

Automation with user-defined features | Advanced

Learning content A Customized Process Feature (CPF) is used when standard features for holes or pockets are no longer sufficient. CPFs can also be used to define company-specific standards for related geometries. This further automates the programming process. Proven workflows are saved as technology macros and can be reused for similar machining tasks. Course content:…

-

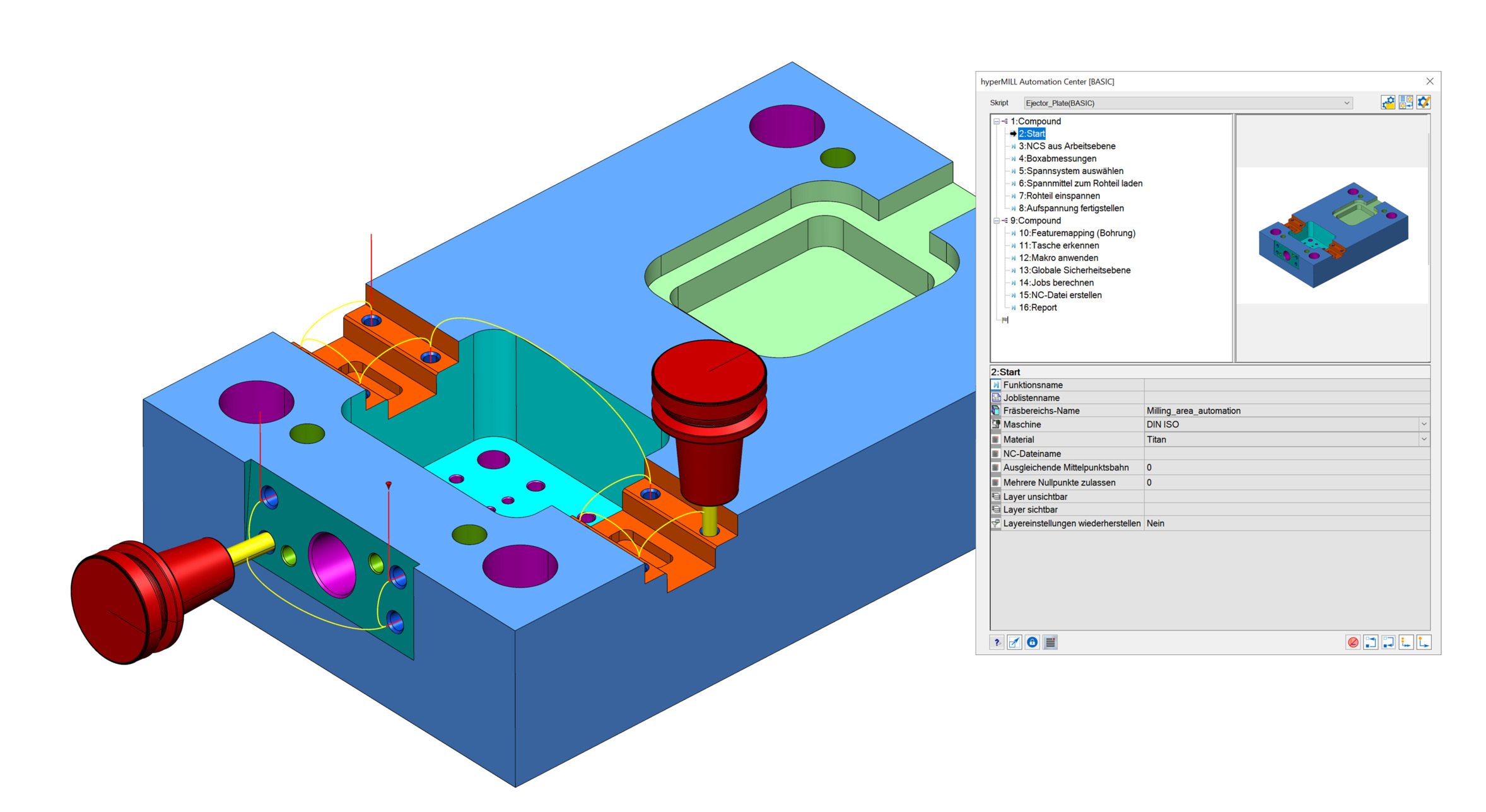

hyperMILL Virtual Tool (automatic tool search) | Advanced

Learning content The VIRTUAL Tool can not only determine the optimum tools based on various machining parameters, but also adapt the machining processes. For example, it decides whether thread forming, tapping or thread milling makes the most sense for the material in question. Machining processes are controlled by user-defined rules and automatically adapted to the…

-

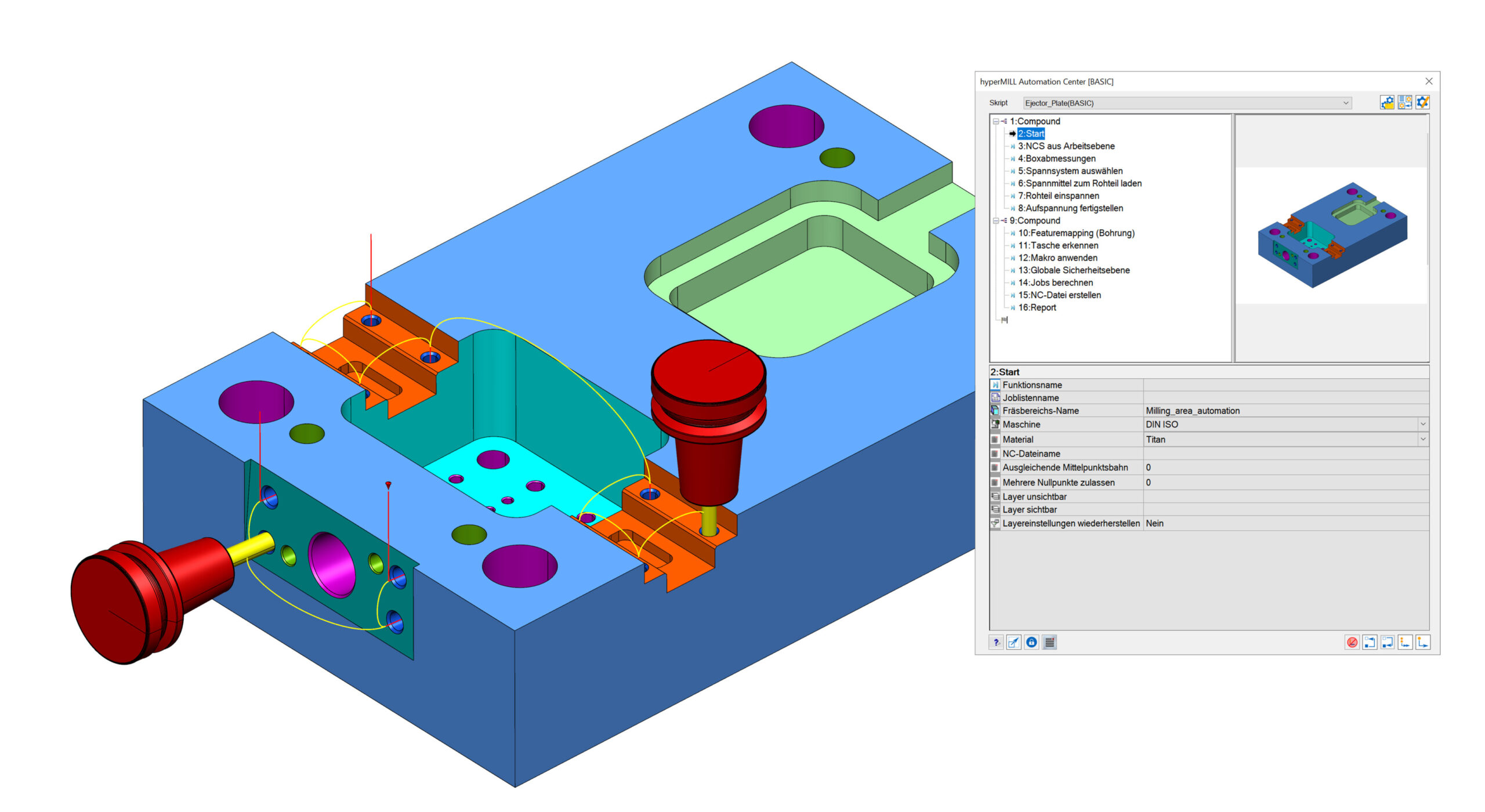

Automated programming (AC Basic) | Advanced

Learning content In this course you will learn how to automate various work steps in hyperMILL and thus significantly reduce the programming effort, e.g. automated programming of repetitive geometries (pockets, holes, etc.). Course content Training dates Gladly there for you Training overview

-

Automated programming (AC Basic) I Basic

Learning content In this course you will learn how to automate various work steps in hyperMILL and thus significantly reduce the programming effort, e.g. automated programming of repetitive geometries (pockets, holes, etc.). Course content Training dates Gladly there for you Training overview

-

Automation Center Advanced

Optimization of the entire workflow from CAD import to NC code output. Apply automation for future projects.

-

Automation Center Basic

The flexible modular system for basic CAM automation processes. Next Step: Automation Center Advanced.

-

Feature/macro programming

This reduces errors and automates recurring geometries with intelligent feature and macro technology.

-

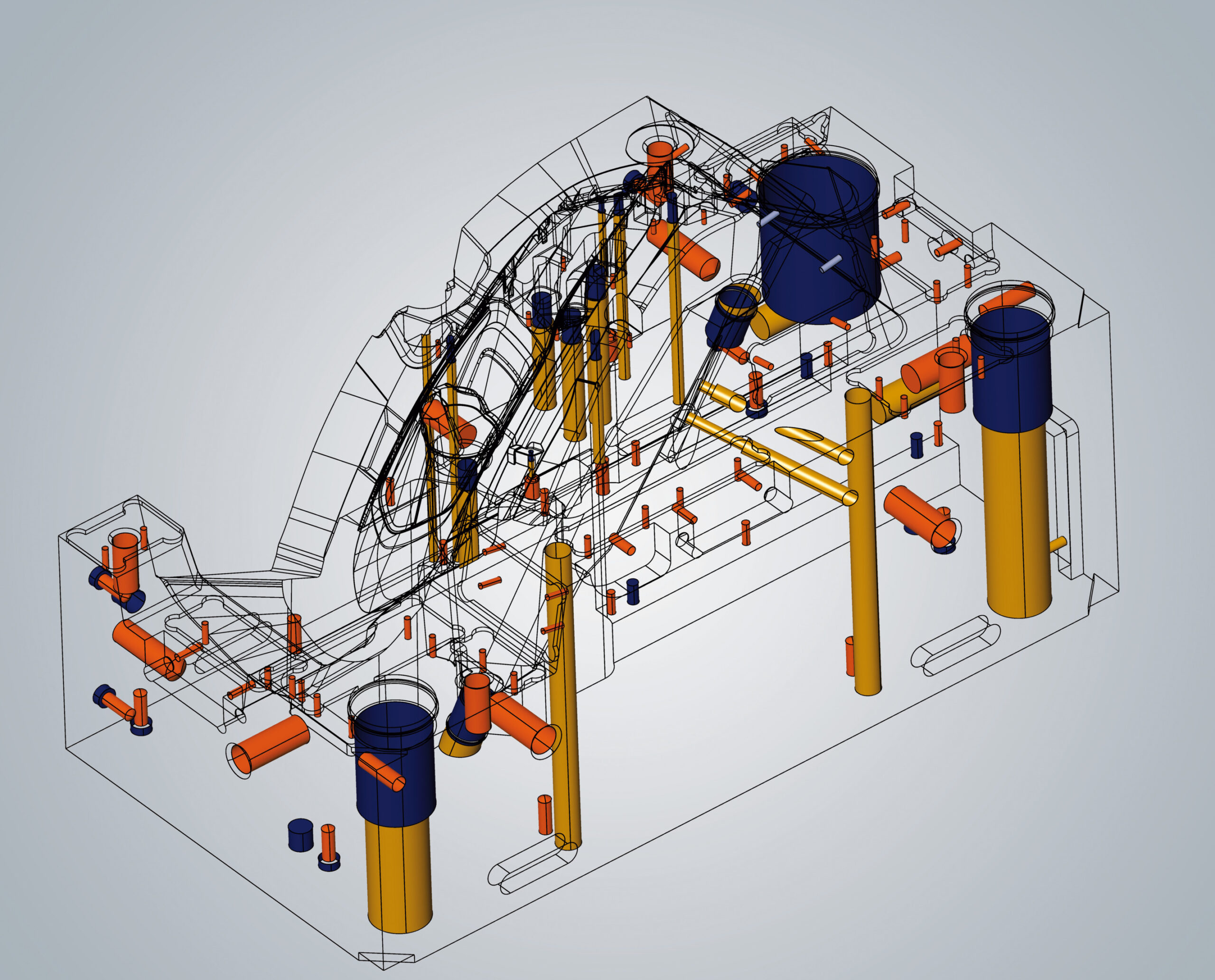

hyperMILL Automation

Comprehensive options for standardizing and optimizing NC programming. A clever opportunity to combat the shortage of skilled workers.

-

CAM automation

Making CAM processes fit for the future: Optimizing CNC programming with powerful tools for automation.

Mechatronics & Robotics

Mechatronics & Robotics