Competence: 3D Metrology

-

Metrology Software

The ZEISS Quality Suite combines powerful software tools that enable consistent and efficient quality control.

-

Industrial image processing

our offer in the field of 3dMetrology WORK IN PROGRESS Frequently asked questions

-

Industrial Image processing

Our solutions for industrial image processing offer you powerful tools for analyzing and processing visual data in real time.

-

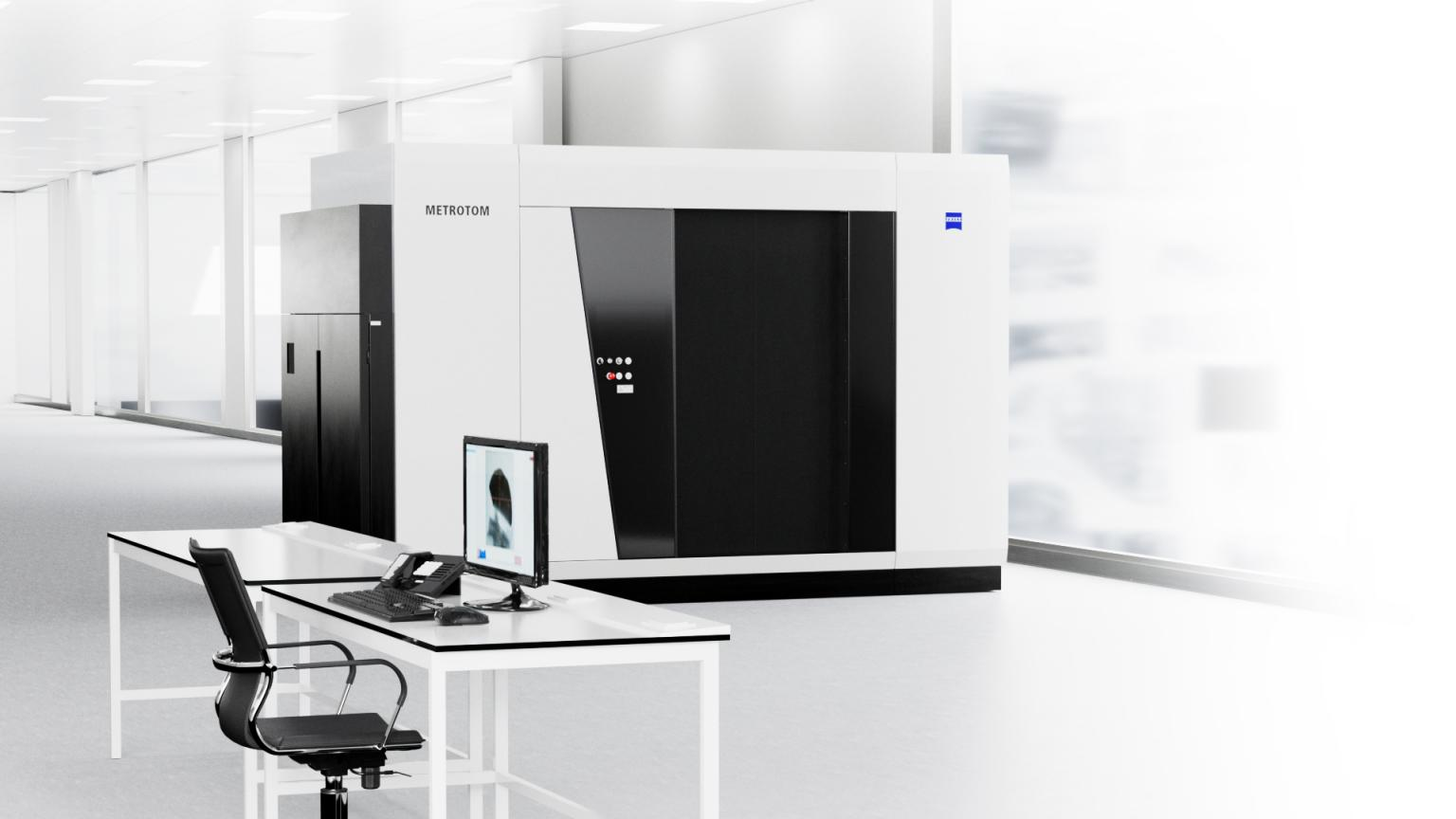

CT – Industrial computed tomography

The view into the component as state-of-the-art technology for geometry and volume evaluation of different components

-

Industrial computed tomography

Industrial computed tomography (CT) from ZEISS sets new standards in the non-destructive testing and analysis of components.

-

ScanBox for eMotors

The ZEISS ScanBox 4105 for eMotors enables efficient and specialized measurement and inspection of hairpins and stators.

-

ScanBox Series 7 & 8

The ZEISS ScanBoxes of the 7 & 8 series enable the 3D inspection of components up to 9 meters in size – with one, or even in parallel with 2 ATOS systems.

-

ScanBox Series 6

Depending on the series, the ZEISS ScanBox Series 6 can carry out 3D inspections of parts up to 3.5 meters in size in one or two measuring ranges.

Mechatronics & Robotics

Mechatronics & Robotics