3D scanning, reverse engineering and 3D printing create an end-to-end digital process from capture to the finished component.

This allows spare and wear parts to be manufactured faster, more precisely and independently of supply chains.

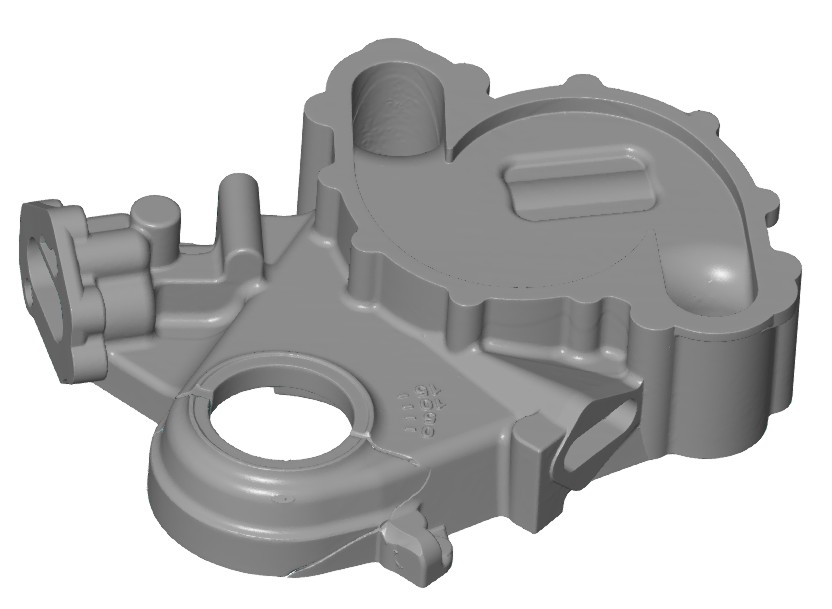

Practical example: defective timing belt cover was recorded, reconstructed and printed in optimized form in just one working day.

The challenge

In industrial production, a single defective component can bring entire systems to a standstill. But what can you do if original drawings are missing or the manufacturer has long since stopped supplying spare parts?

This is where the combination of 3D scanning, reverse engineering and 3D printing comes in – a digital process that radically simplifies the procurement of spare parts.

The process

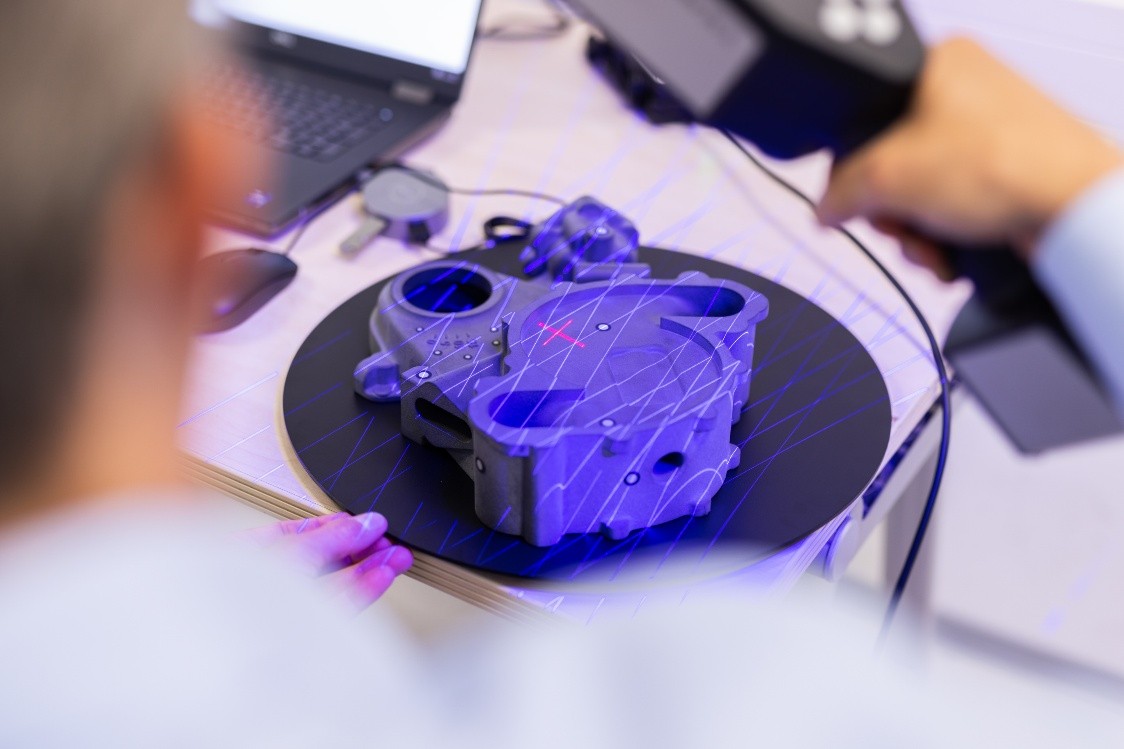

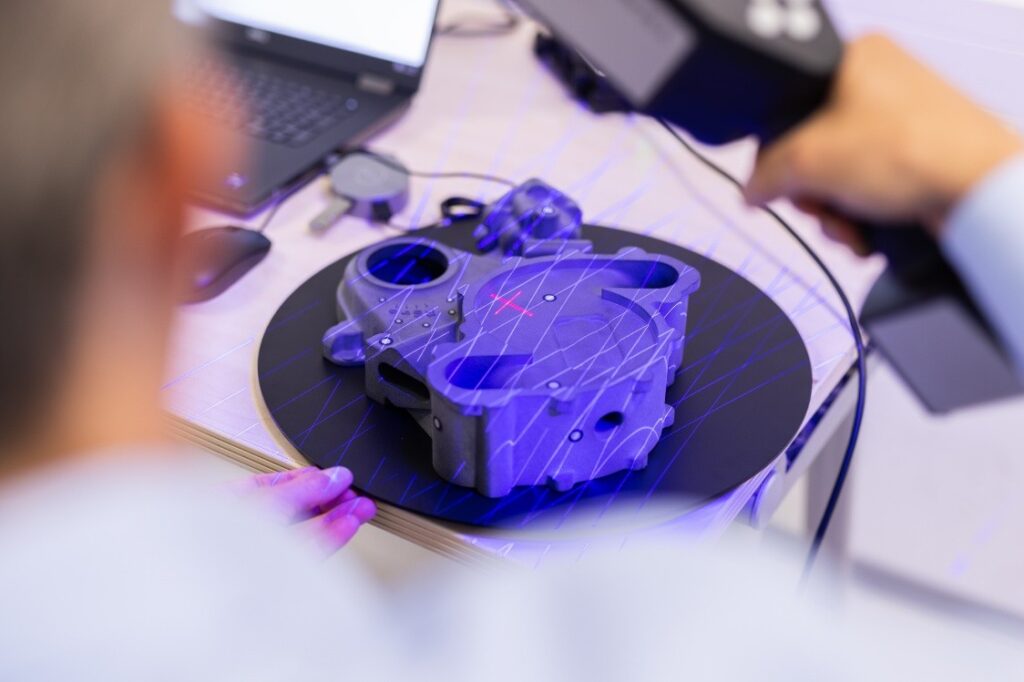

Step 1: 3D scan – the digital basis

Before anything can be printed, it must be available digitally.

High-precision 3D scanners are used to capture the existing part – even if it is damaged – to an accuracy of a hundredth of a millimetre. Different methods are used:

Laser scanners, Structured Light scanners or even CT scanners for internal structures.

This creates an exact digital image of the component within a few minutes.

The advantage: Even complex geometries or fine details can be reconstructed – regardless of whether CAD data exists or not.

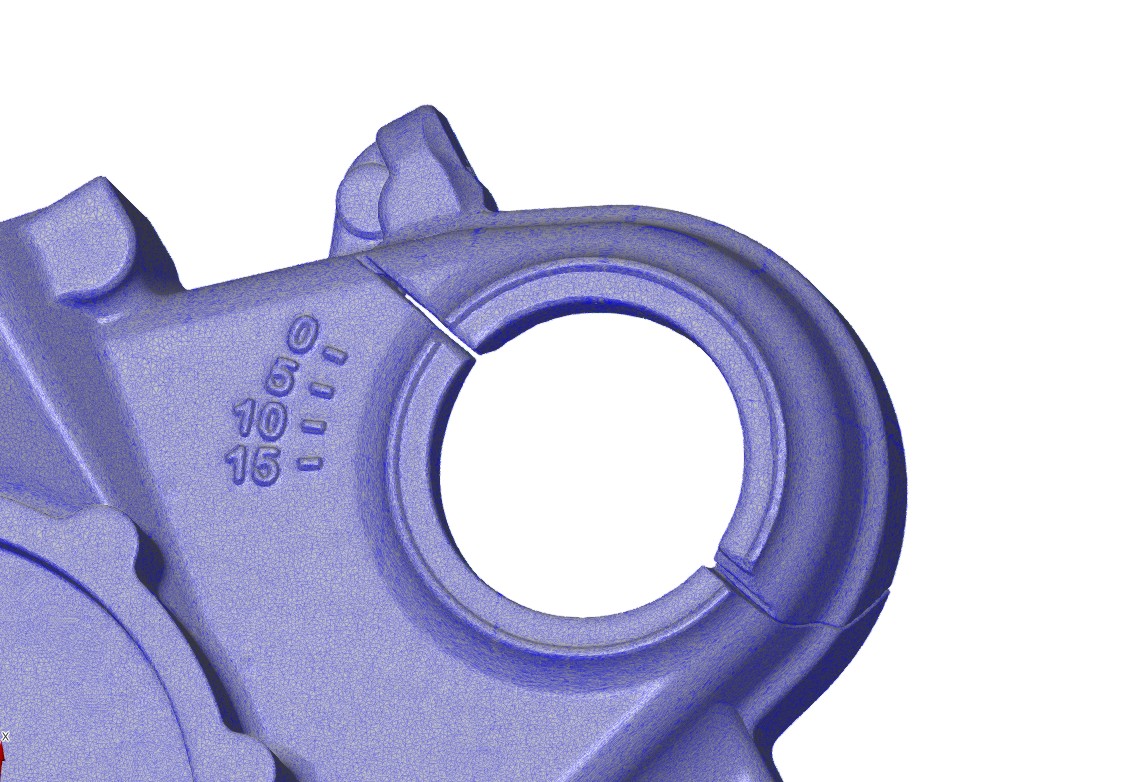

Step 2: Reverse engineering – from scan to model

Engineers digitally reconstruct the component based on the scan data. Missing geometries are added, weak points are identified and, if necessary, improved.

The result is a 3D model that can be used for design purposes and either corresponds to the original or has been specifically optimized – for example through topology optimizations or adaptations to operating conditions.

This makes reverse engineering the decisive link between reality and digital production.

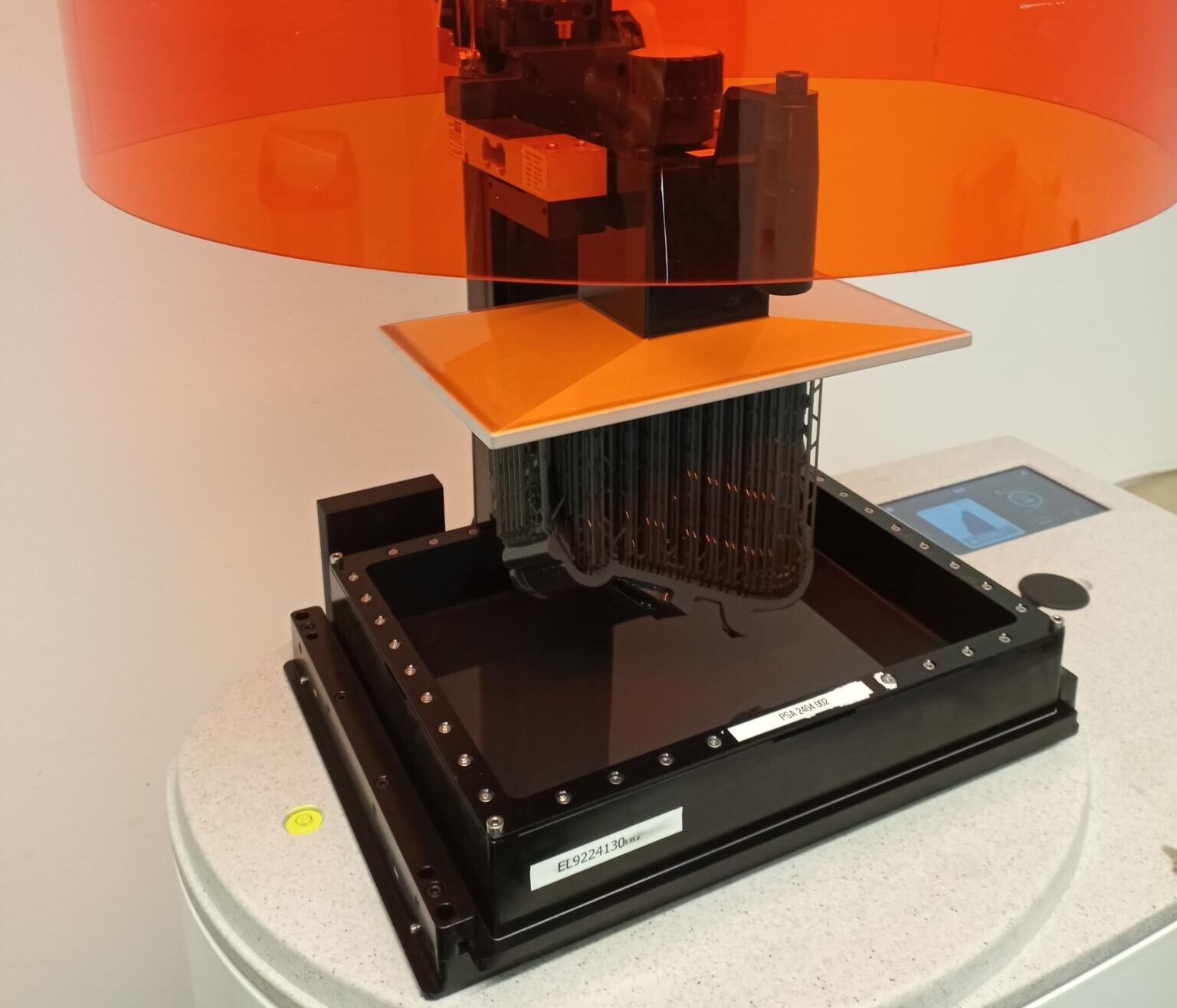

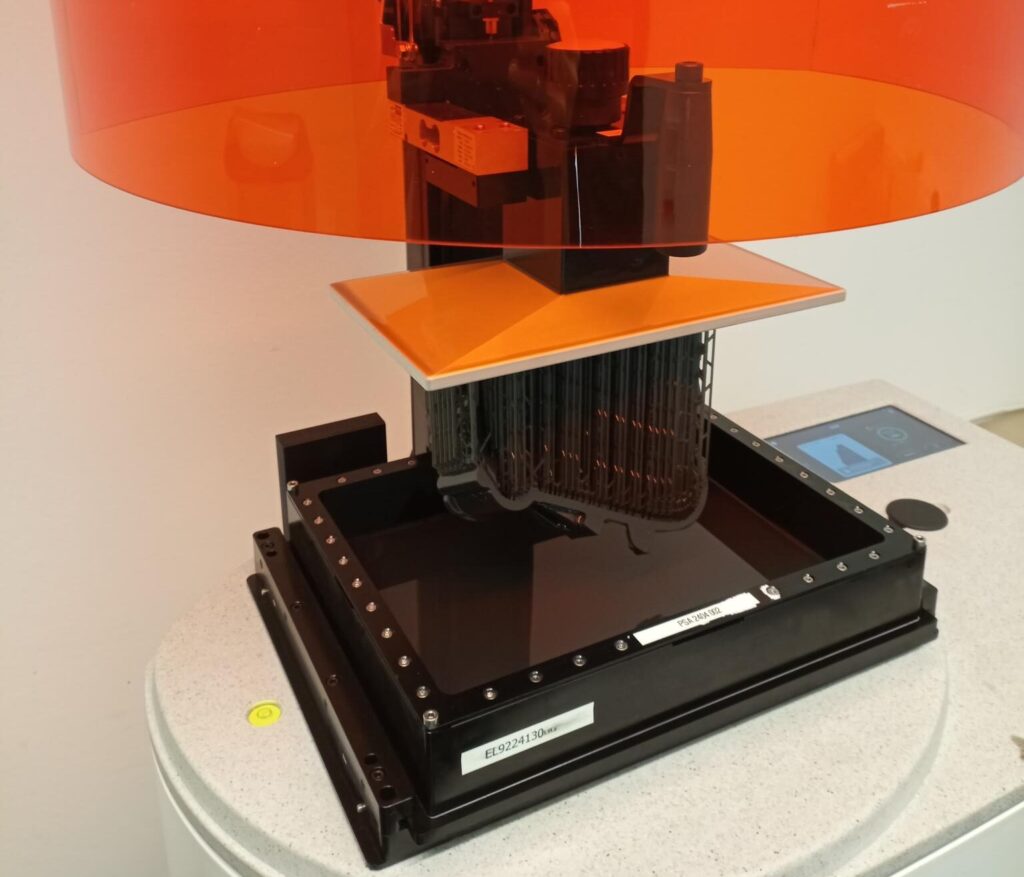

Step 3: 3D printing – from model to ready-to-use spare part

The physical component is then created from the digital model – layer by layer, precisely and functionally.

The right process is selected depending on the application:

From plastic printing processes such as FDM or SLS to metal-based technologies such as Laser Powder Bed Fusion or Electron Beam Melting.

The result: precisely fitting spare parts in the shortest possible time – without tool costs, without delivery bottlenecks, without downtime.

You want to reproduce your parts individually and quickly. This is possible with our 3D printing services:

The interplay: digital, fast, independent

The true strength lies in the interaction of these technologies.

A defective part is scanned → digitally reconstructed → optimized → and directly reprinted.

This creates a seamless, fully digital process that dissolves traditional supply chain dependencies and drastically reduces downtimes.

Thanks to the digitalized process of 3D scanning, reverse engineering and 3D printing, spare parts are not only produced faster and more independently, but are also much more resource-efficient. Materials are used in a targeted manner, transport routes are eliminated and existing components can be optimized instead of being completely redeveloped. The result is a sustainable form of spare parts production that combines efficiency and environmental awareness.

Our practical example shows what this looks like in reality:

A defective timing belt cover was replaced within a few hours using 3D scanning, reverse engineering and 3D printing – from capture to installation within one working day.

quickly and cost-effectively

Detailed information on the procedure can be found in our e-book “Spare & wear parts”.

Get your FREE e-book NOW:

Want even more practice?

WEBINAR: From ScAnning to the finished spare part: 3D technologies in use

Find out in just 42 minutes how you can use 3D scanning, reverse engineering and 3D printing to reproduce defective or unavailable spare and wear parts quickly, precisely and economically. Our experts will show you the entire process – from the damaged original part to the ready-to-use spare part – and the advantages that modern 3D technologies offer for your maintenance.

WESTCAM – Your partner for digital spare parts production

With decades of experience in 3D scanning, design and additive manufacturing, we support companies from the initial idea to the finished spare part. Whether a single piece or a small series – every part counts.

And if it is to be newly manufactured, then it should be better than the original.

Mechatronics & Robotics

Mechatronics & Robotics