A new innovative product often fails due to high tool costs and long lead times? HSS technology is your direct answer!

High Speed Sintering (HSS) stands out among all 3D printing processes due to its large build spaces, fast build speed and high recycling rate. It is the key to flexible, fast and cost-efficient production of polymer parts. Don’t hesitate to test us.

High Speed Sintering (HSS): The technology in detail

HSS is an advanced binder jet technology for processing plastics.

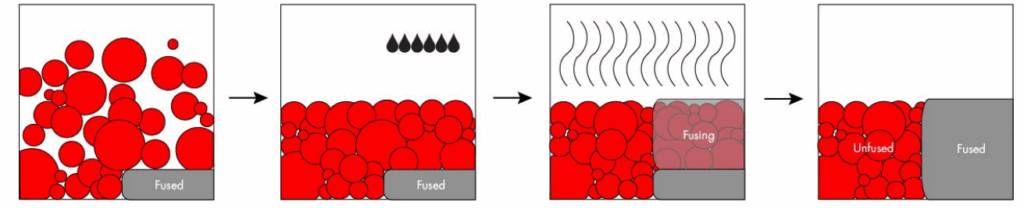

The process begins with the application of a thin layer of polymer powder, such as PA12 or thermoplastic polyurethane (TPU), onto a heated building platform.

An industrial inkjet print head moves over the powder bed and precisely applies an energy-absorbing binder (absorber) only in those areas that will later form the solid component.

After the absorber has been selectively applied, the entire powder layer is irradiated with infrared light . The areas previously printed with the absorber absorb the energy of the IR light more than the unprinted areas. They heat up beyond the melting point of the polymer and sinter together.

The unprinted powder areas, on the other hand, remain below the melting temperature and therefore loose. After this sintering process, the build platform is lowered by one layer thickness and the process starts again. Layer by layer, a high-precision component is created.

Large installation spaces, which are usually difficult to control with conventional laser processes, can be realized with BinderJetting in a stable and safe process. Small components in very large installation spaces achieve the highest productivity and the lowest price. The price difference compared to injection-molded components virtually disappears.

The unbeatable advantages of HSS for the production of your components

HSS technology is perfect for the industrial production of polymer parts – ideal for small batches and mass customization.

- Speed: We sinter entire layers simultaneously. For you, this means shorter throughput times and higher part output. Your

- Component properties: HSS parts impress with their high density, excellent strength and dimensionally accurate precision. Hardly any distortion, consistent results!

- Sustainable: We recycle almost 100 % of the non-sintered powder. This saves costs and is sustainable.

- Design freedom & functional integration: We realize complex geometries and lightweight structures. By directly integrating functions and combining several components in one, we reduce assembly and maintenance costs, which increases the cost-effectiveness of your product.

Find out more about the HSS process and 3D printing in our 3D printing Start2Print basic training

Your partner for the 3D printing challenge

HSS technology has enormous potential for innovative products and efficient manufacturing processes. But to fully exploit this potential, you need the right know-how and the right infrastructure. This is precisely where our services come in. We accept your 3D printing challenge!

- Engineering & data creation:

Do you have an idea that needs to be 3D printed? We are your partner from the concept to the finished 3D print file. Our experts will be happy to support you in designing your product for 3D printing. - Process and material selection:

Which material fulfills the required properties of my application? Which process delivers the desired material properties? These two essential questions already show that process and material are not always compatible. Sometimes the desired properties can only be achieved through appropriate post-processing. Our specialists will be happy to help you find the right production process to meet the requirements of the component. - Production: From individual parts to small series to series production:

Whether you need prototypes for testing, a small series for market launch or are planning series production of your products – we are your reliable partner. We guarantee reproducible results and can also take care of the necessary post-processing steps to give your parts the finishing touches.

WESTCAM as your extended workbench

Challenge us – we accept any 3D printing challenge and deliver precise, on-time and top-quality printed parts.

Our 3D printing service is ideal for pilot projects or individual productions. You can test your options flexibly and without risk:

Contact us today for a no-obligation consultation

We look forward to turning your 3D printing ideas into reality!

Mechatronics & Robotics

Mechatronics & Robotics