ETEC Envision One

ETEC Envision One – High-speed production of functional components

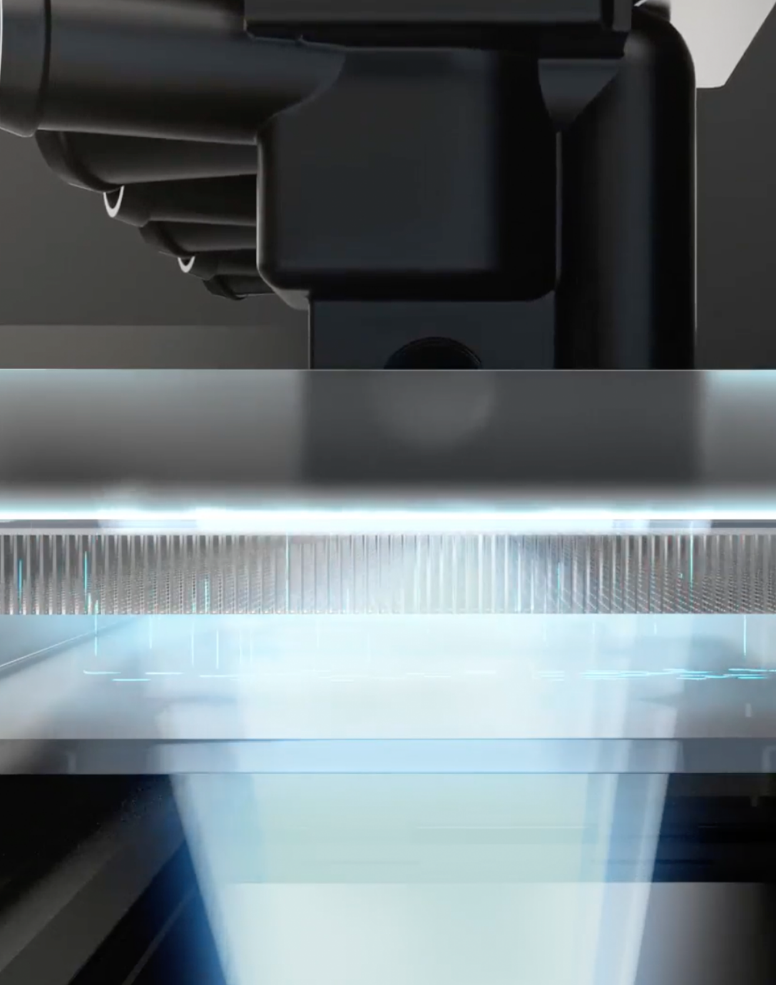

The Envision One features patented CDLM (Continuous Digital Light Manufacturing) technology, which enables continuous printing.

With little to no delay between layers, the Envision One delivers exceptional speed, print resolution, surface finish and part properties.

- High-speed 3D printing

- High accuracy and resolution

- Best-in-class parts performance

High-speed 3D printing

Complete a full 3-liter build volume in just 4.5 hours – 30% faster than competing systems and 10 times faster than desktop SLA.

High accuracy and resolution

With the patented “domeless” printing technology, the Envision One eliminates inaccuracies on the Z-axis that could affect the print result.

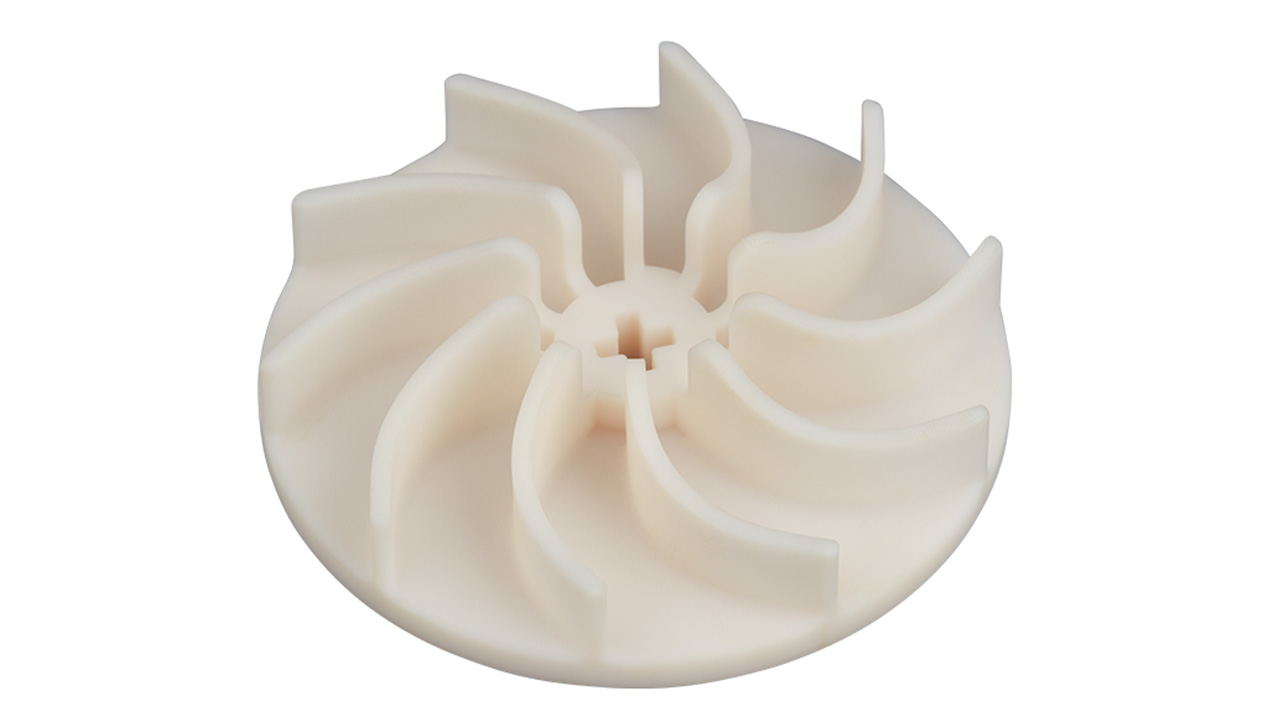

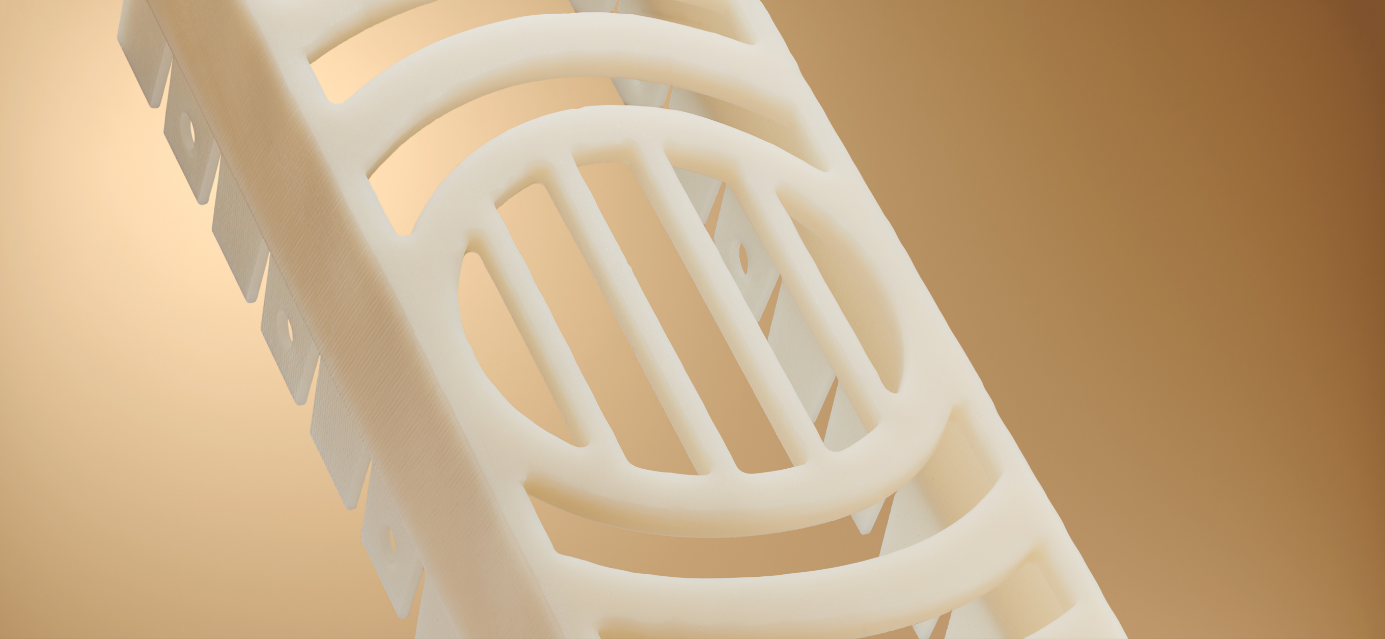

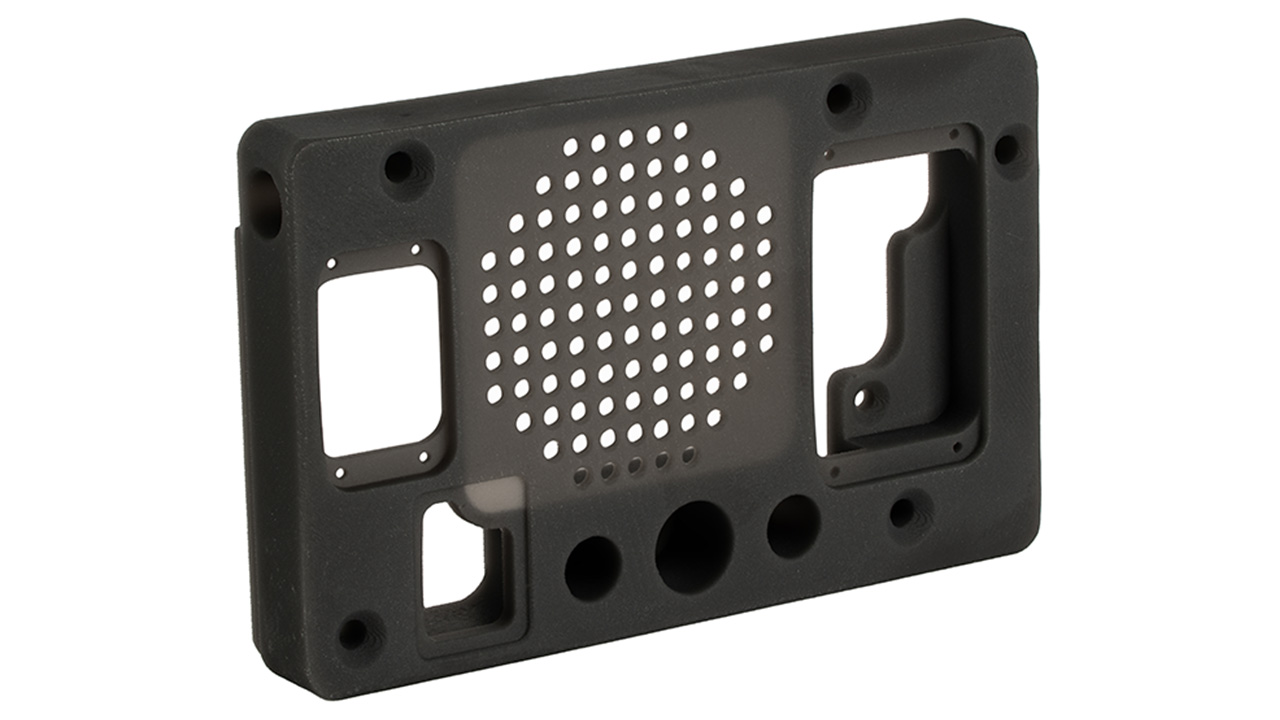

High-resolution (60 µm XY) printing and patented pixel tuning technology make it easy to create the fine features and smooth surfaces that are essential for end-use parts.

Best-in-class parts performance

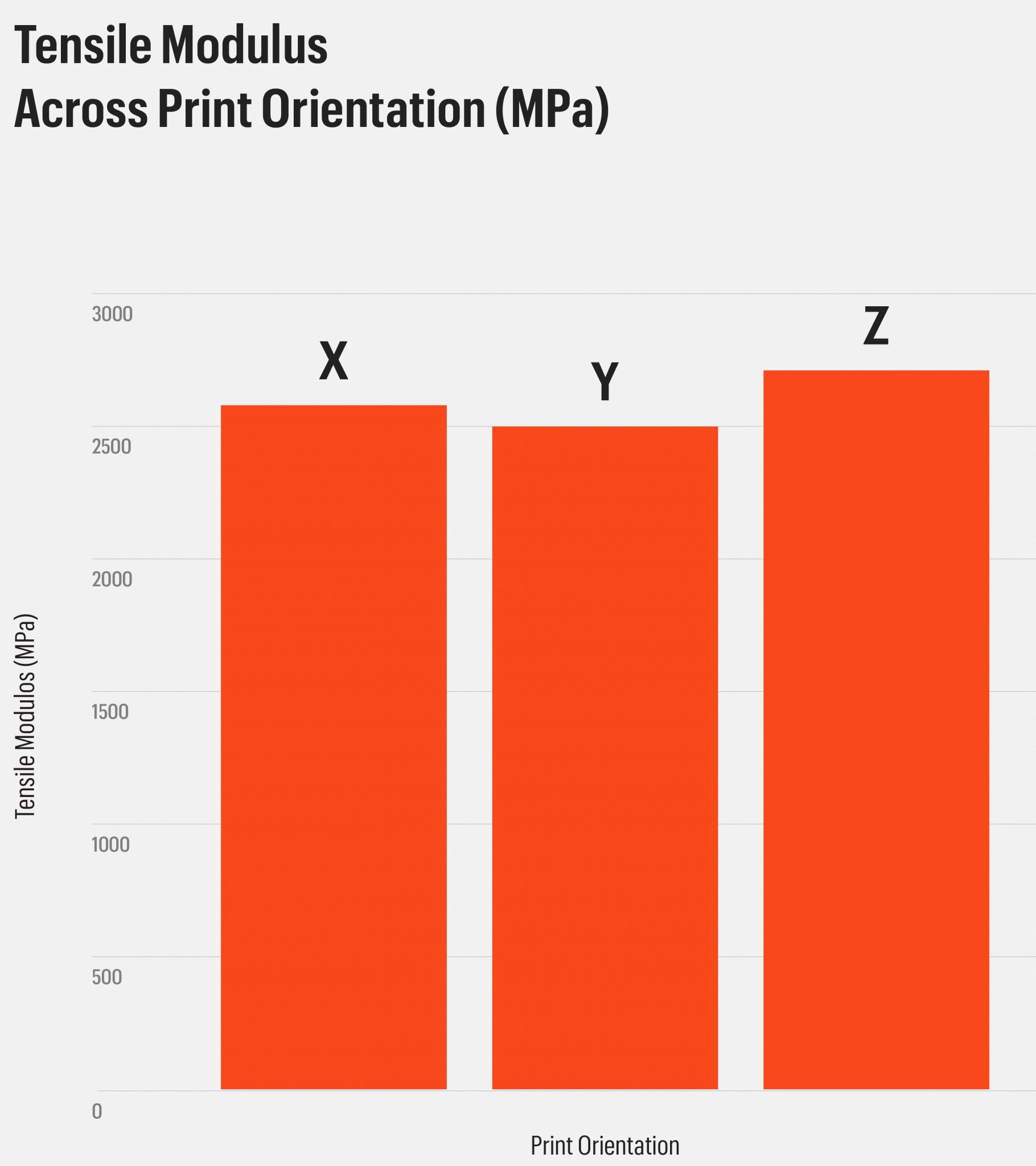

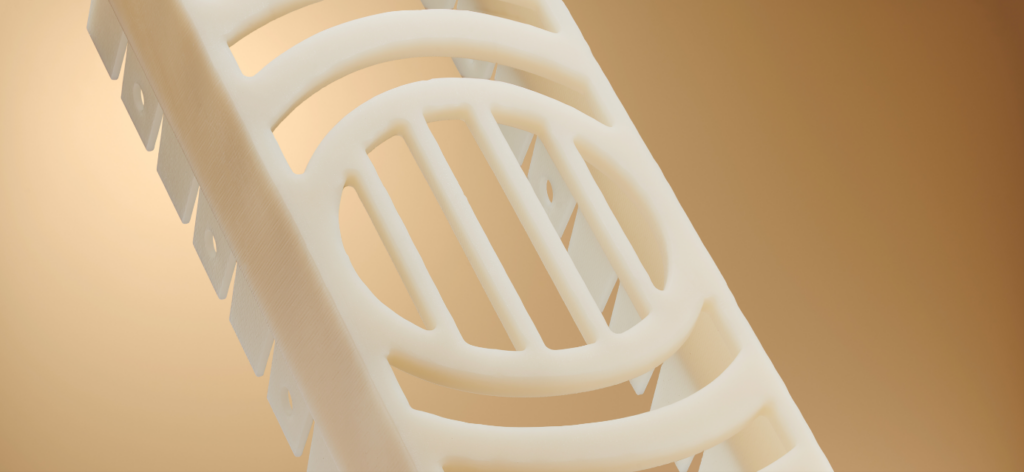

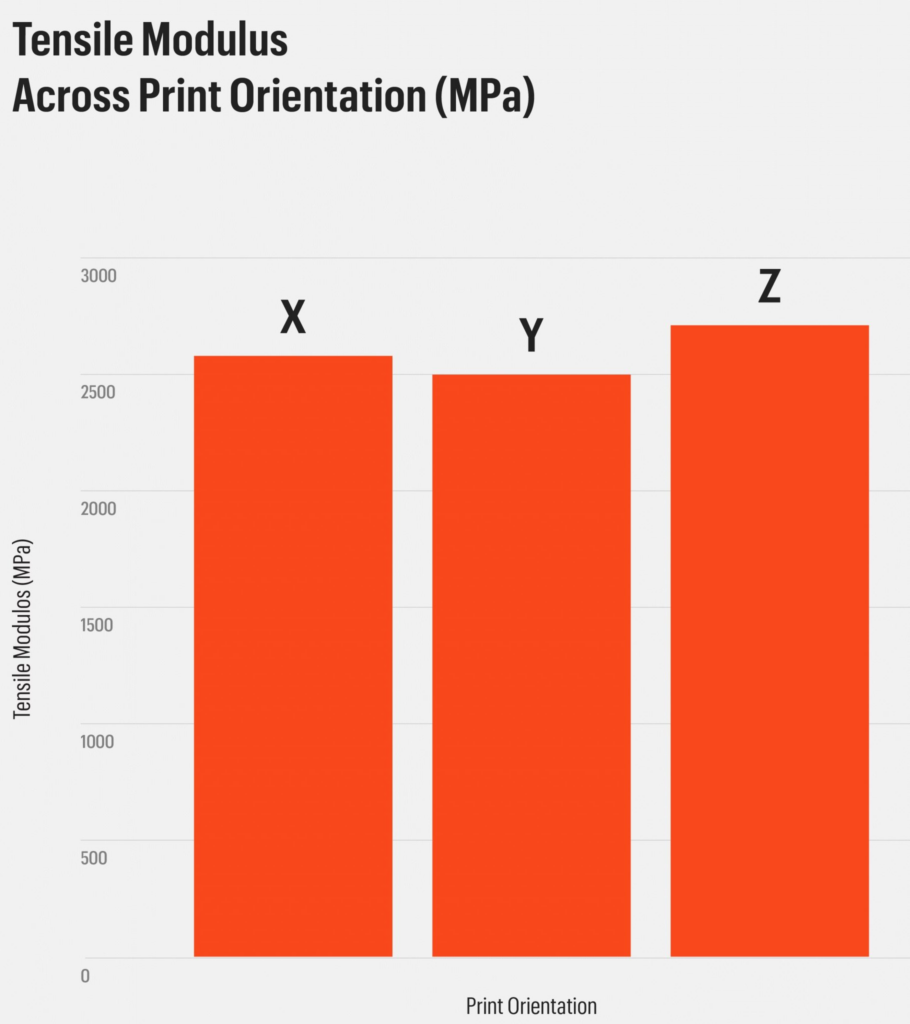

The Envision One uses the chemistry of long-chain polymers to produce strong, stable parts.

The result is isotropic parts that are suitable for end applications and can withstand the most demanding conditions.

Frequently asked questions (FAQs)

How fast can the ETEC Envision One produce objects, and what factors influence this speed?

The ETEC Envision One offers a high printing speed made possible by its advanced DLP technology. The speed depends on several factors, including the layer thickness and the materials used. The complexity of the components does not play a role for the Envision One. The printer utilizes digital light processor technology, which allows it to achieve fast exposure times for each layer, reducing overall production time. For exact print speed and further customization, consider the printer’s specifications and recommended print settings for your specific applications.

How does the ETEC Envision One ensure high print quality for complex parts?

The ETEC Envision One ensures high print quality thanks to its high resolution and DLP technology, which enables precise exposure of the print surface. The finest layer thicknesses and uniform exposure ensure that even complex and detailed parts are printed with high accuracy and a smooth surface.

Mechatronics & Robotics

Mechatronics & Robotics