- Component optimization & identification of faulty concepts at an early stage of development

- Reduced development costs

- Little waste of material

- Shorter time-to-market for product launches

- Better visualization & coordination internally between the individual departments

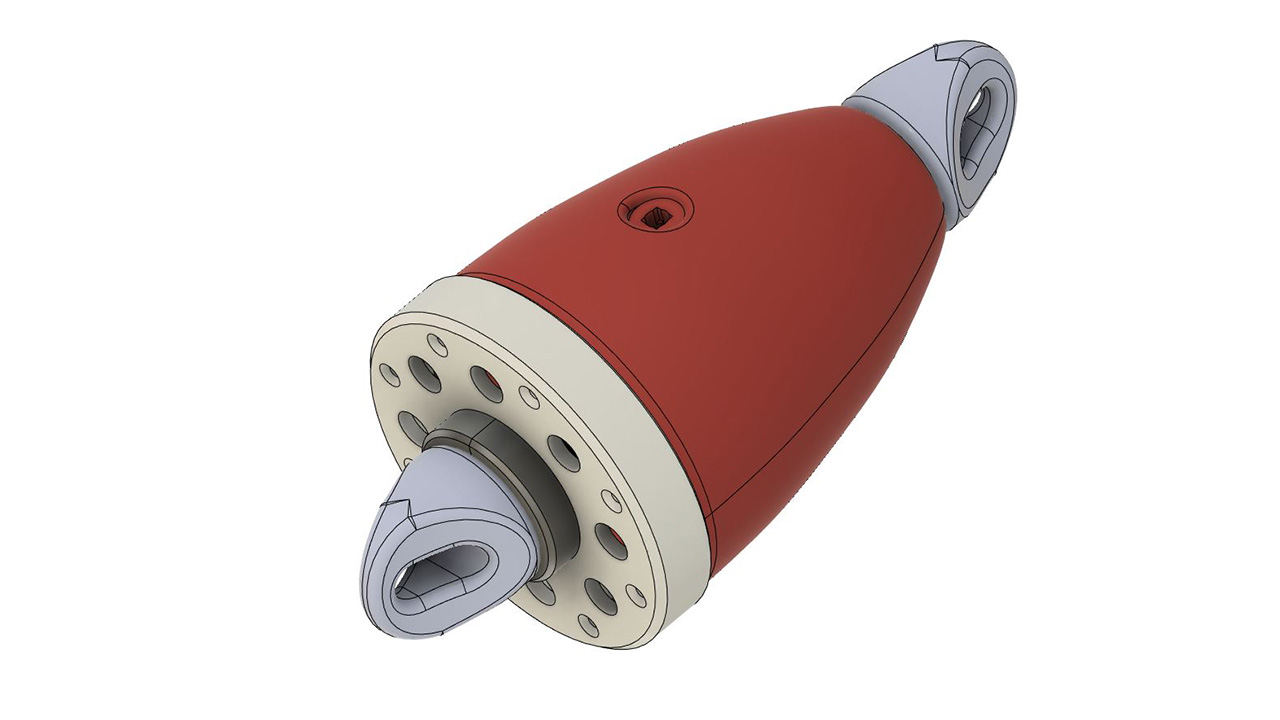

Individual parts & prototypes

No matter which industry you serve: Before your idea, product or component goes into series production, it must be tested in a variety of ways.

The best way to do this is to produce a functional prototype. This can be done particularly quickly and cost-effectively with the help of additive manufacturing.

Using a functional model from the 3D printer, you can check at an early stage of development:

- Are all moving parts working?

- Does the component achieve the desired values in terms of temperature resistance, breaking strength, etc.?

- Do all dimensions and contours fit?

- Are the proportions of the parts and the feel right?

- Can anything else be improved?

Thanks to functional prototypes, design and development can be checked and weak points identified at an early stage. This is because deficits and optimization potential often only become apparent on the actual object. Additional necessary design features can then be added for production in the next step and unnecessary parts can be eliminated.

WESTCAM supports you in the production of your technical prototypes. Take advantage of our many years of expertise and the diversity of our manufacturing options. We will find the optimum solution for your needs and will be happy to advise you.

Advantages of functional prototypes

The advantages of functional prototypes before series production are obvious:

- Component optimization & identification of faulty concepts at an early stage of development

- Reduced development costs

- Little waste of material

- Shorter time-to-market for product launches

- Better visualization & coordination internally between the individual departments

WESTCAM supports you in the production of your technical prototypes. Take advantage of our many years of expertise and the diversity of our manufacturing options. We will find the optimum solution for your needs and will be happy to advise you.

Frequently asked questions (FAQs)

Warum funktionale Prototypen aus dem 3D Drucker?

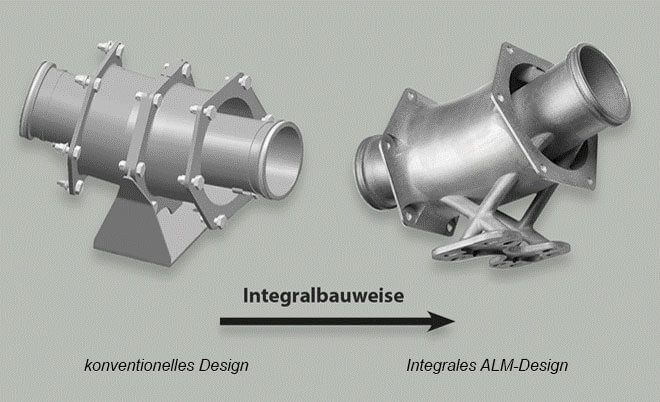

By using modern 3D printing technology, functional prototypes can be produced faster and more cost-effectively than with conventional manufacturing processes.

Prototypes and components from the 3D printer impress with their precision, level of detail, dimensional accuracy and thermal stability. Additive manufacturing can even be used to produce extremely intricate prototypes that would be impossible or very difficult to produce using other methods.

Was wird für die Herstellung eines Prototypens im 3D Drucker benötigt?

The basis for the production of a functional prototype is the 3D CAD model. You can provide us with your own model or let our WESTCAM 3D printing experts help you create the necessary data. We will be happy to help you adapt and optimize your data sets so that you can achieve the best possible printing result.

Welches 3D Druckverfahren wird für die Herstellung von funktionalen Prototypen verwendet?

There are different 3D printing processes. Which process is used for your functional prototype is highly individual. Our WESTCAM 3D printing experts will work with you to select the most suitable process and material for your prototype.

You can get an overview of the most important 3D printing processes here:

Welche Branchen profitieren von Prototypen aus dem 3D Drucker?

3D printing has become an integral part of many industries. Many companies benefit from the use of additive manufacturing in their production chain: from the concept model to the prototype to series production. Industries that benefit from functional prototypes from the 3D printer include the medical sector, aerospace, architecture, defense, the film industry and the automotive industry.

Mechatronics & Robotics

Mechatronics & Robotics